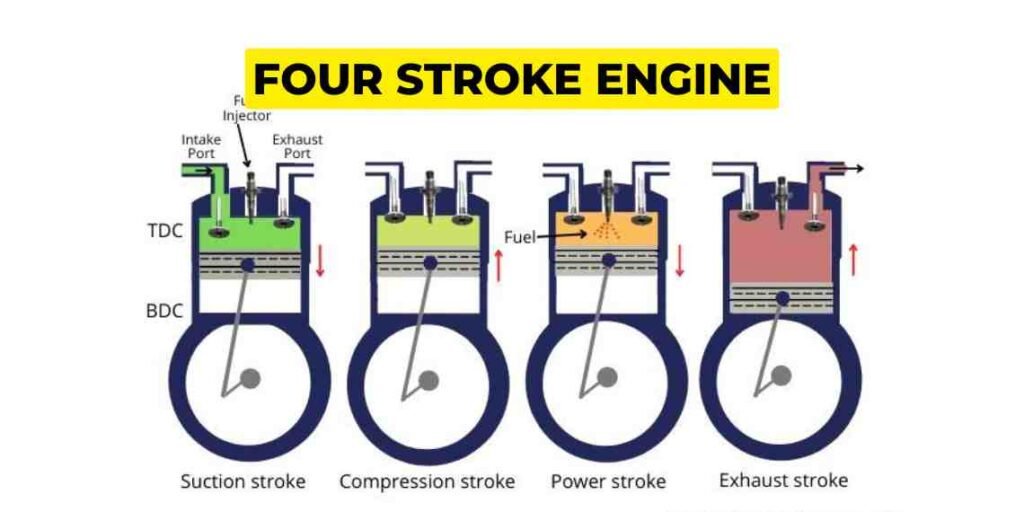

The four different strokes of an engine are intake, compression, power, and exhaust. They move the piston to produce energy and expel gases in a repeating cycle.

Pistons in an internal combustion engine perform four distinct operations: intake, compression, power, and exhaust. For example, in a four-stroke engine, the piston must move up and down twice (two complete revolutions of the crankshaft) in order to complete one cycle of these strokes. Each cycle consists of (in order) the intake of a fresh air/fuel mixture, compression of that mixture in preparation for combustion, and the clearing of the exhaust gases.

These four operations must all work in tight coordination to valve and crankshaft timing. Modern fuels and emissions technology focus on the benefits of this four-stroke cycle. This cycle is the backbone of all gasoline and diesel engine technologies.

Contents

What Are the 4 Different Strokes of an Engine?

Knowing each distinct stroke explains the method of energy formation in the engine. The piston movement, valve openings, and changes in pressure work together to create energy that can be usefully converted to mechanical work on a fuel.

1. Intake Stroke

The intake stroke begins as the piston moves down from TDC to BDC. During this movement, the intake valve opens, and the exhaust valve closes. This drop creates lower pressure in the combustion chamber, allowing the fresh air-fuel mixture to be drawn in from the intake manifold. This mixture’s quantity and quality directly influence the engine’s performance and efficiency, and the intake stroke sets the stage for what will be compressed and ignited before.

In modern engines, fuel = is precisely metered by fuel injectors during this phase. This way, the combustion chamber gets the desired air-fuel ratio for complete combustion. This leaves no room for oscillating in quality or timing of the mixture. Otherwise, these lead to unwanted engine power and emissions.

2. Compression Stroke

Once the intake stroke is finished, the piston begins the compression stroke. The intake and exhaust valves are closed. The piston starts BDC and moves towards TDC. This will increase the pressure and temperature of the air-fuel mixture as the volume is decreased. The higher the compression. the better combustion will be. Designers of the engines have to decide the compression ratios that best fit the performance and fuel needs.

This is important as compression determines how quickly the fuel can be burned. If compression is too high then knocking or pinging can begin, and if too low then the engines power will be low and the fuel will be wasted.

3. Power Stroke

The power stroke is the most important stroke of the four strokes because this is the stroke that is producing usable energy. When the compression stroke finishes and TDC is reached, the mixture is ignited. In diesel engines, this is done by compression heat, while in gas engines this is done by a spark plug. Because of this high rapid rise in heat and pressure from the burning gases, the piston is driven back down towards BDC and is done so forcefully.

That downward movement transfers flowed energy through the connecting rod to the crankshaft, and torque is produced that ultimately moves the vehicle or drives the machine. Therefore, the power stroke is also known as the “combustion stroke”.

Due to the modern engines, there are advanced control systems added to the fuel injection and ignition timing, which, in turn, helps to provide the maximum power for that stroke. Under various loads, control units help to avoid knocking and control spark timing for the optimal operational efficiency.

4. Exhaust Stroke

The vertical position of the piston after combustion should be in a position such that it should push out the exhaust gases to leave space for the new mixture to come in. During the exhaust stroke, the piston moves from the bottom dead center (BDC) position to the top dead center (TDC) position and during this process, the exhaust valve opens and as a result of this process, the used gases are expelled out of the cylinder and through the exhaust system.

It is important to have properly working exhaust scavenging because unburnt or partially burnt gases can weaken the power of the combustion charge and increase the exhaust. Some High performance vehicles use exhaust valves that are slightly opened more to improve the combustion process.

How it Works as a Whole

The four distinct strokes of the engine piston are highly synchronized with the camshaft and crankshaft of the engine. Each stroke represents a 180 degree rotation of the crankshaft. Thus, a complete four-stroke cycle requires two full revolutions (720 degrees) of the crankshaft. During this cycle, the combustion chamber mixture is allowed to enter and exit at the correct cycles, the camshaft opens and closes the valves at the correct times.

Only the power stroke generates useable energy. The other three strokes prepare and clear the combustion chamber; therefore, power can be produced repeatedly, and the cycle continues thousands of times per minute whenever the engine is running.

Why the Four Strokes Matter

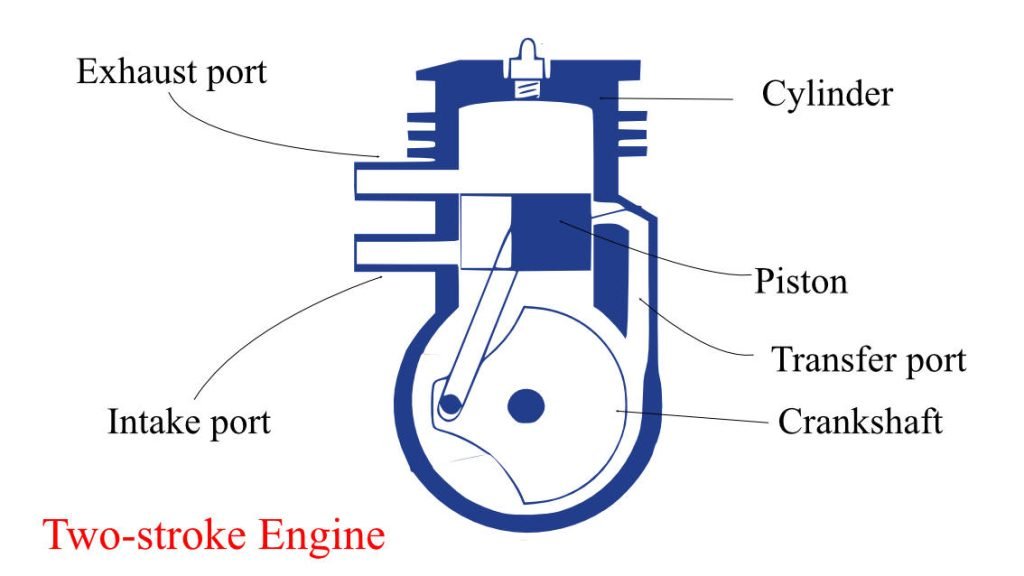

The four different strokes of an engine provide a balanced and effective way to produce mechanical work from the chemical energy stored in fuel. Four stroke engines provide cleaner exhaust, better fuel economy, and a longer life than two stroke engines. The clear separation of tasks–intake, compression, power, exhaust–allows for better performance and better emissions.

Real-World Examples of Four-Stroke Engines

A good balance of efficiency, power, and cost is why four-stroke engines are used in most passenger cars, trucks, and motorcycles. In cars, multiple cylinders perform the same cycle, but are staggered to ensure smooth power delivery at all speeds. The same cycle is also used in small engines of lawn equipment and generators to provide consistent motion.

Engine Design and Components

To make the four different strokes of an engine work, several major components must interact:

- Cylinder: where combustion occurs.

- Piston: moves up and down inside the cylinder.

- Crankshaft: converts piston motion into rotation.

- Camshaft: opens and closes valves.

- Valves: control intake and exhaust flows.

- Spark Plug or Injector: initiates combustion.

Together, these parts make sure the right mixture enters, gets compressed, burns, and is then expelled.

Engine Valve Timing and Overlap

The opening and closing of valves are synced with the piston strokes, and piston strokes are dead center endpoints. To enhance gas flow, engineers allow valve events to start and end before and after piston strokes. An overlap between intake and exhaust valves can provide better efficiency, and performance of engines, but, excessive overlap can negatively affect low and mid-speed performance of an engine.

Adjusting valve timing makes it possible to achieve the desired balance of performance, emissions, and reliability.

Engine Thermodynamics and the Four Strokes

Each of an engine’s four strokes can also be analyzed using the thermodynamic principles of the Otto cycle. In the Otto cycle, heat and work transfer occur at specific locations of piston movement. In the intake and exhaust strokes, pressure changes occur with very little heating or cooling (temperature). In the compression and power stroke, there is a significant change in both pressure and temperature.

This cycle essentially describes the process of converting the chemical energy in fuel to mechanical energy, and it is among the most important concepts for engineers in the field of automobiles.

Related Article

How Many Strokes Are in a 2 Cycle Engine?

Frequently Asked Questions

Here are some common questions about a four stroke engine –

1. Why do you need two revolutions of the crankshaft for each four-stroke cycle?

One full cycle of the crankshaft is accomplished by each of the four strokes: intake, compression, power, and exhaust. That is a total of 720 degrees of shaft rotation.

2. Are the four strokes made during the cycle all power strokes?

Not all the strokes create power. Only the power stroke gives effectual mechanical energy. The intake, exhaust, and compression strokes make room for clearers of the combustion chambe.

3. What is the effect of having valves open at the wrong times?

This can lead to an increase in the power that is being used, an increase in the waste products that are being produced , and a increase in the diseased parts of the engine.

4. Why Are four Stroke Engines More Common Than Two-Stroke Engines?

This is the result of the four-stroke engine being overall less expensive for the consumer. Although the four-stroke engine has more design and manufacturing costs compared to the two-stroke engine.

Conclusion

The four stages of an engine illustrate the cyclical phenomenon of transforming chemical energy into mechanical energy in an internal combustion engine. Each cycle consists of intake, compression, power, and exhaust strokes, where a carefully controlled sequence of actions fuels air mixture, compresses it to enhance combustion, forces exhaust fluid from the gas, and clears exhaust fluid. The cycle balances power, efficiency, and emission control, and therefore it is the benchmark for modern automotive and small-engine design.