The brake rotor provides a surface for friction to stop the vehicle, while the hub assembly supports the wheel and bearings for smooth rotation. Together, they ensure safe and effective braking. Regular maintenance is essential to prevent issues.

Braking systems are arguably the most critical components of any vehicle. Among the many parts that contribute to safe and effective braking, the brake rotor and hub assembly are key players. These components, although often overlooked, ensure that a vehicle can stop quickly and efficiently.

In this article, we’ll dive into the intricacies of the brake rotor and hub assembly, including their functions, how they work, and why they are crucial to your vehicle’s safety and performance.

Contents

Brake Rotor and Hub Assembly

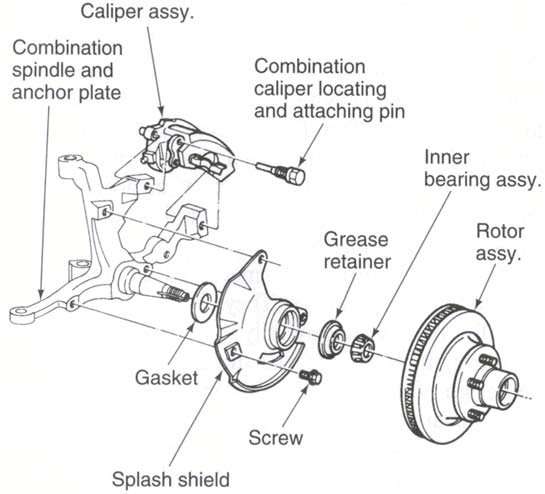

The brake rotor and hub assembly are part of the disc brake system, commonly used in modern vehicles. Disc brakes provide better heat dissipation and stopping power than older drum brakes. The assembly combines two essential parts:

- Brake Rotor (Disc): The brake rotor, also known as the brake disc, is a circular metal plate connected to the wheel hub. It spins along with the wheels. When the brake is applied, the calipers squeeze the brake pads against the rotor, creating friction to slow down or stop the wheel’s rotation.

- Hub Assembly: The hub assembly, also called the wheel hub or wheel hub unit, is the central part that houses the wheel bearings. It provides the mounting point for the brake rotor and the wheel, ensuring that the wheel stays connected to the vehicle’s axle and rotates smoothly. It also plays a role in maintaining the alignment and stability of the vehicle.

The brake rotor and hub assembly work in unison to ensure your vehicle stops safely and effectively.

Functions of the Brake Rotor and Hub Assembly

The brake rotor and hub assembly are essential components of a vehicle’s braking system. Here’s a breakdown of their individual functions:

Brake Rotor (Disc)

The brake rotor is responsible for providing the surface area on which the brake pads act to create friction and stop the vehicle. When you press the brake pedal, hydraulic pressure pushes the brake calipers, which in turn push the brake pads against the rotor. This friction generates heat, which is dissipated by the rotor’s design, preventing the brakes from overheating and maintaining their effectiveness.

- Heat Dissipation: High-quality brake rotors are designed with vents or grooves to allow better air circulation, which helps in dissipating heat. Overheating can lead to brake fade, where the brakes lose their effectiveness, so a well-designed rotor is crucial to maintaining braking performance during repeated or heavy use.

- Smooth Braking: A properly functioning brake rotor ensures smooth and consistent braking without vibrations. Warped or damaged rotors can cause vibrations when braking, leading to uncomfortable driving and reduced brake efficiency.

- Material and Durability: Brake rotors are typically made from cast iron due to its high thermal resistance and cost-effectiveness. However, for performance vehicles, rotors may be made of materials like carbon-ceramic, which offer even better heat resistance, reduced weight, and longer lifespan.

Hub Assembly

The hub assembly is responsible for several critical tasks related to the wheel’s attachment and the vehicle’s overall stability. It contains the wheel bearings, which allow the wheel to rotate freely and reduce friction.

- Wheel Alignment and Stability: The hub assembly plays a vital role in keeping the wheel aligned. If the hub assembly or the wheel bearings are damaged, the vehicle’s steering and alignment can be affected, leading to uneven tire wear or difficulty steering.

- Support for ABS Sensors: In modern vehicles, the hub assembly also supports the Anti-lock Braking System (ABS). It often contains a sensor or tone ring that monitors the wheel’s rotational speed, sending signals to the ABS to prevent the wheels from locking up during sudden stops.

- Bearing Support: The bearings within the hub assembly allow the wheel to rotate with minimal friction. Over time, wheel bearings can wear out, leading to noise, vibrations, and potential damage to the rotor and other suspension components.

Signs of a Failing Brake Rotor and Hub Assembly

Regular maintenance is essential to ensure the brake rotor and hub assembly remain in good condition. Here are some common signs that indicate potential issues:

Vibration While Braking

One of the most common signs of a warped brake rotor is a noticeable vibration when you press the brake pedal. This can be caused by uneven wear or heat spots on the rotor, leading to inconsistent friction during braking.

Squealing or Grinding Noise

A high-pitched squeal when braking can indicate that the brake pads are worn and need to be replaced. If left unaddressed, worn pads can grind against the rotor, causing deep grooves and necessitating rotor replacement.

ABS Light Illuminated

If the ABS light comes on, it could signal a problem with the hub assembly, particularly the ABS sensor or tone ring. In such cases, a diagnostic scan can identify whether the issue lies in the hub or elsewhere in the braking system.

Wheel Play or Wobble

Excessive wheel play or wobble can be a sign of a damaged hub assembly or worn wheel bearings. This issue can affect the vehicle’s alignment, causing steering issues and uneven tire wear.

Increased Stopping Distance

If it takes longer than usual to bring your vehicle to a stop, it could be a sign of warped rotors or worn hub assembly components. Reduced braking efficiency is dangerous and should be addressed immediately.

Causes of Brake Rotor and Hub Assembly Issues

Several factors can contribute to the wear and tear of the brake rotor and hub assembly. Understanding these causes can help you maintain the longevity of these components:

Overheating

Frequent hard braking, especially in performance or heavy-duty driving conditions, can cause the brake rotor to overheat. Over time, this can lead to warping or cracking.

Corrosion

Rust and corrosion can affect both the brake rotor and hub assembly, especially in regions with harsh weather conditions or where road salt is used. Corrosion can weaken the rotor’s structure and cause the bearings in the hub assembly to seize up.

Improper Installation

Improper installation of brake components, such as unevenly torquing the wheel nuts or using the wrong size rotor, can cause issues with both the rotor and hub assembly.

Lack of Maintenance

Neglecting regular brake inspections and maintenance, such as checking for worn brake pads, can lead to damage to the brake rotor. Likewise, ignoring worn wheel bearings can cause damage to the hub assembly.

Maintenance and Replacement

The maintenance and replacement of the brake rotor and hub assembly are important for ensuring the safety and efficiency of a vehicle’s braking system. Here’s a guide to proper maintenance and the steps for replacement.

Brake Rotor Maintenance: Regular inspections can help identify issues like warping, cracks, or excessive wear. If a rotor is warped but still has sufficient thickness, it may be possible to resurface it. However, if the rotor is worn beyond the manufacturer’s recommended thickness, it must be replaced.

Hub Assembly Maintenance: Unlike brake rotors, hub assemblies are not typically resurfaced but replaced when they fail. Wheel bearings within the hub assembly are subject to wear over time and can be replaced if necessary. Signs of a failing hub include noisy wheel bearings, excessive wheel play, and ABS sensor malfunctions.

Replacement Costs: The cost of replacing a brake rotor can vary widely based on the vehicle and rotor material. Standard cast-iron rotors are more affordable, while performance rotors like carbon-ceramic ones are more expensive. Hub assembly replacements are typically more expensive due to the complexity of the part and the labor involved.

Frequently Asked Questions

Here are some FAQs about brake rotor and hub assembly –

1. How long do brake rotors and hub assemblies last?

Brake rotors can last anywhere between 30,000 to 70,000 miles, depending on driving habits and conditions. Hub assemblies typically last 100,000 miles or more but may wear out sooner under heavy load conditions or if exposed to harsh environments.

2. Can I drive with a bad hub assembly?

Driving with a bad hub assembly is not recommended. A failing hub can cause steering and stability issues, and in extreme cases, the wheel may even detach from the vehicle. If you notice signs like wheel wobbling or strange noises, have it inspected immediately.

3. What causes brake rotors to warp?

Brake rotors typically warp due to excessive heat. This can happen from frequent hard braking, towing heavy loads, or driving in mountainous areas. Warping causes uneven wear, leading to vibrations during braking.

4. What happens if you don’t replace a bad wheel bearing?

Ignoring a worn or failing wheel bearing can lead to wheel instability, increased wear on tires, and eventually cause the wheel to seize up, which can be extremely dangerous.

5. Can I replace just the brake rotor without replacing the hub assembly?

Yes, you can replace the brake rotor without replacing the hub assembly, provided the hub is still in good condition. However, if the hub assembly is worn or damaged, it’s wise to replace both components simultaneously to ensure optimal performance.

Conclusion

The brake rotor and hub assembly are fundamental components in your vehicle’s braking system, contributing to both safety and performance. Understanding their functions, how to identify potential issues, and how to maintain them properly can extend their lifespan and improve overall vehicle performance. Regular maintenance and prompt attention to signs of wear can prevent costly repairs and ensure your vehicle operates safely.