Yes, a faulty crankshaft position sensor can cause a no-spark condition. The sensor provides crucial data to the ECU for controlling ignition timing, and if it fails or sends incorrect signals, the ECU may not trigger the ignition system properly. This can prevent the spark plugs from firing, leading to a no-start situation.

The crankshaft position sensor (CKP sensor) is one of the most critical components in modern internal combustion engines. It plays a crucial role in ensuring that the engine runs efficiently by monitoring the position and rotational speed of the crankshaft. This information is then relayed to the engine control unit (ECU), which uses it to regulate ignition timing and fuel injection.

A malfunctioning CKP sensor can lead to a variety of engine issues, including a no-spark condition, which prevents the engine from starting or running properly.

Contents

Can Crankshaft Position Sensor Cause No Spark?

A no-spark condition occurs when the spark plugs fail to ignite the air-fuel mixture in the engine cylinders. This can be caused by several factors, including issues with the ignition system, fuel delivery, or sensor malfunctions. Here’s how a faulty CKP sensor can lead to a no-spark condition:

- No Signal to ECU: The CKP sensor provides the ECU with the information needed to determine the crankshaft’s position. If the sensor fails completely, it may stop sending signals to the ECU. Without this information, the ECU cannot determine when to trigger the ignition coils, leading to a no-spark condition.

- Incorrect Timing Signals: If the CKP sensor is sending erratic or inaccurate signals, the ECU may misinterpret the crankshaft’s position, causing the ignition system to fire at the wrong time or not at all. This can result in no spark reaching the spark plugs, preventing the engine from starting.

- Interruption in Ignition Sequence: The CKP sensor is responsible for synchronizing the ignition sequence with the crankshaft’s rotation. A faulty sensor can disrupt this synchronization, leading to missed or erratic ignition events. In severe cases, this can cause the engine to stall or fail to start due to no spark.

- Impact on Other Engine Sensors: The CKP sensor works in conjunction with other engine sensors, such as the camshaft position sensor (CMP sensor), to provide the ECU with accurate data. If the CKP sensor fails, it can cause the ECU to disregard signals from other sensors, further contributing to a no-spark condition.

- Fail-Safe Mode: Some modern vehicles have a fail-safe mode that the ECU enters when it detects a critical sensor failure, like that of the CKP sensor. In this mode, the ECU may cut off the ignition system to prevent potential engine damage, leading to a no-spark condition.

Preventing Crankshaft Position Sensor Cause No Spark Issues

While it’s not always possible to prevent a CKP sensor from failing, regular maintenance and timely repairs can help reduce the risk:

- Routine Inspections: Have the CKP sensor and its wiring inspected regularly during routine maintenance to catch potential issues early.

- Address Symptoms Early: If you notice symptoms like engine stalling, no start condition, or a check engine light, address them promptly to avoid more serious problems.

- Use High-Quality Parts: When replace crankshaft position sensor, use high-quality OEM or equivalent parts to ensure reliability and longevity.

Frequently Asked Questions

Here are some FAQs about the no spark issues –

1. What happens if the crankshaft position sensor goes bad?

If the crankshaft position sensor is bad, the ECU may not receive the necessary data to time the ignition and fuel injection correctly, leading to no spark, engine stalling, or a no-start condition.

2. Can a bad crankshaft position sensor cause intermittent starting issues?

Yes, a faulty CKP sensor can cause intermittent starting issues due to erratic signals being sent to the ECU, leading to inconsistent ignition timing and spark delivery.

3. How do you test a crankshaft position sensor?

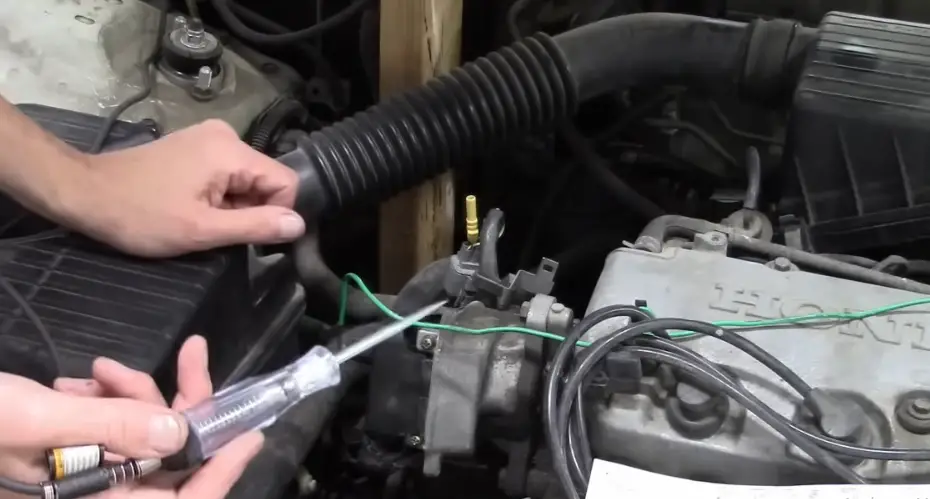

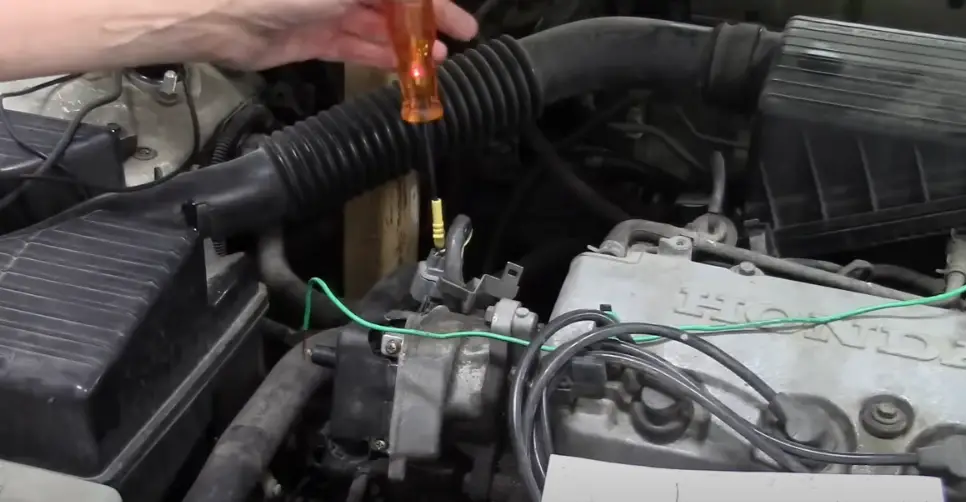

A CKP sensor can be tested using a multimeter to check its resistance and output signal. In some cases, an oscilloscope may be used to analyze the sensor’s signal waveform.

4. Is it safe to drive with a failing crankshaft position sensor?

Driving with a failing CKP sensor is not recommended, as it can lead to engine misfires, stalling, and a no-spark condition, potentially leaving you stranded.

5. How much does it cost to replace a crankshaft position sensor?

The cost of replacing a crankshaft position sensor typically ranges from $100 to $250, depending on the vehicle make and model, including parts and labor.

Conclusion

The crankshaft position sensor is a vital component of the engine’s ignition system. When it fails, it can lead to a no-spark condition, preventing the engine from starting or running properly. Understanding the role of the CKP sensor, recognizing the symptoms of its failure, and knowing how to diagnose and replace it can help you address no-spark issues promptly and keep your engine running smoothly.