Engine Control Module (ECM) problems can lead to poor performance, starting issues, and stalling. Common causes include faulty sensors, electrical shorts, or water damage. Diagnosing and fixing ECM issues may involve repair or replacement, which can be costly. Addressing these problems promptly is crucial for optimal vehicle operation.

The Engine Control Module (ECM), also known as the Engine Control Unit (ECU), is one of the most critical components of modern vehicles. It acts as the brain of the engine, managing various functions such as fuel injection, ignition timing, air-fuel mixture, and emissions control. When the ECM experiences problems, it can lead to various performance issues, or in severe cases, make the vehicle inoperable.

In this comprehensive blog post, we will explore the common problems associated with the ECM, their symptoms, causes, and possible solutions.

Contents

- 1 What is an Engine Control Module (ECM)?

- 2 Common Engine Control Module Problems

- 3 Diagnosing ECM Problems

- 4 ECM Repair and Replacement Costs

- 5 Preventing ECM Problems

- 6 Frequently Asked Questions

- 7 Conclusion

What is an Engine Control Module (ECM)?

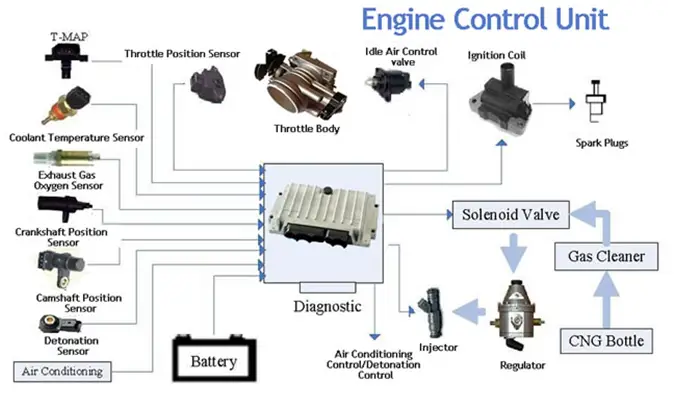

The ECM is a computer system that monitors and controls engine performance. It receives data from various sensors, processes the information, and sends commands to different actuators to optimize engine functions. The goal of the ECM is to ensure that the engine operates efficiently while meeting emission standards.

Key Functions of the ECM

The Engine Control Module (ECM) plays a critical role in vehicle performance by managing various engine functions. Here are the key functions of the ECM:

- Fuel Injection Control: The ECM regulates the amount of fuel injected into the engine based on real-time data from various sensors, optimizing fuel efficiency and performance.

- Ignition Timing: It controls the timing of the spark plug firing, ensuring proper ignition of the air-fuel mixture for efficient combustion.

- Air-Fuel Mixture Regulation: The ECM monitors and adjusts the air-fuel ratio to maintain optimal combustion conditions, enhancing engine efficiency and reducing emissions.

- Emissions Control: It manages the operation of emissions control systems, such as the catalytic converter, to comply with environmental regulations and minimize harmful exhaust emissions.

- Monitoring Engine Performance: The ECM continuously monitors various engine parameters, including temperature, pressure, and RPM, to ensure the engine operates within specified limits.

- Diagnostics and Error Codes: It detects malfunctions in engine systems and stores trouble codes that can be read using an OBD-II scanner, helping mechanics diagnose issues effectively.

By performing these functions, the ECM ensures that the engine operates efficiently, safely, and in compliance with emissions standards.

Common Engine Control Module Problems

Here are some common problems associated with the Engine Control Module (ECM):

1. Corrosion or Water Damage

One of the most common causes of ECM failure is exposure to moisture. Water can seep into the ECM housing due to leaks, condensation, or improper seals. When water or moisture gets inside, it can cause electrical shorts, corrode connections, and damage sensitive electronic components.

Symptoms:

- Erratic engine behavior

- Unpredictable stalling or starting issues

- Fault codes related to multiple systems

- Complete failure of the ECM to function

Solution:

Check for signs of water ingress near the ECM unit. If water damage is found, the ECM may need to be replaced, and the source of the leak must be fixed to prevent future issues.

2. Electrical Overload or Short Circuit

An ECM can be damaged by electrical surges or shorts in the vehicle’s electrical system. This can occur due to faulty wiring, a failing alternator, or issues with other electrical components.

Symptoms:

- Blown fuses

- Persistent engine misfires

- Irregular warning lights

- The engine fails to start

Solution:

Diagnose the vehicle’s electrical system to find the source of the overload or short. A professional mechanic may use a multimeter to check for wiring issues, blown fuses, or component failures that need repair before replacing the ECM.

3. Faulty Sensors or Actuators

The ECM relies on data from various sensors (such as oxygen sensors, MAF sensors, and temperature sensors) to make decisions about fuel injection, ignition, and emissions control. If one of these sensors fails or provides inaccurate data, it can cause the ECM to make incorrect adjustments, leading to performance problems.

Symptoms:

- Poor engine performance (loss of power, rough idle)

- Increased fuel consumption

- Trouble codes related to sensor malfunctions

- Check engine light (CEL) illuminates

Solution:

Use an OBD-II scanner to retrieve trouble codes and identify the faulty sensor(s). Replacing the defective sensor usually resolves the issue. In some cases, reprogramming the ECM may also be necessary.

4. Software Glitches or Firmware Issues

The ECM operates using complex software that governs all its functions. Over time, bugs in the software or corrupt firmware can lead to problems with how the ECM processes data and controls the engine. In such cases, the ECM may start sending incorrect commands to various systems.

Symptoms:

- Sudden engine power loss

- Transmission shifting issues

- CEL comes on intermittently

- Inconsistent or random performance issues

Solution:

Reflashing or updating the ECM software is often the solution to software-related issues. This involves resetting the ECM to its original factory settings or applying a software update provided by the manufacturer.

5. ECM Power Supply Problems

The ECM needs a consistent and stable power supply to function properly. If the ECM doesn’t receive adequate voltage due to issues with the battery, alternator, or wiring, it may not function correctly or may fail completely.

Symptoms:

- The engine won’t start or is hard to start

- Flickering dashboard lights

- Low battery voltage warning

- ECM malfunctions when other electrical systems are in use

Solution:

Check the vehicle’s battery, alternator, and wiring harness for faults. If the power supply to the ECM is interrupted or inconsistent, addressing these issues should restore normal ECM function.

6. ECM Hardware Failure

Over time, internal components of the ECM, such as the capacitors, transistors, or circuits, may fail due to wear and tear or exposure to extreme temperatures. Hardware failure is usually a more severe issue and may require ECM replacement.

Symptoms:

- No communication with diagnostic scanners

- Complete engine shutdown

- Total loss of drivability

Solution:

If hardware failure is confirmed, the ECM will likely need to be replaced or rebuilt. ECM replacement can be expensive but is necessary to restore the vehicle’s operation.

Diagnosing ECM Problems

Diagnosing ECM problems requires both specialized tools and knowledge. Here are the steps usually followed by mechanics:

- OBD-II Scan: Mechanics use an OBD-II scanner to retrieve error codes from the ECM. These codes help identify which systems or sensors are malfunctioning.

- Visual Inspection: The mechanic checks for signs of corrosion, water damage, or burnt electrical components.

- Voltage and Ground Checks: Ensuring that the ECM receives proper voltage and is grounded correctly is critical. Faulty wiring can lead to improper ECM function.

- Sensor Testing: Testing individual sensors, such as the oxygen sensor, throttle position sensor, or MAF sensor, helps identify whether a faulty sensor is causing ECM issues.

- ECM Reflash or Replacement: If all other systems are working correctly, and the ECM itself is found to be faulty, it may need to be reprogrammed or replaced.

ECM Repair and Replacement Costs

The cost of repairing or replacing an Engine Control Module (ECM) can vary widely based on several factors, including the vehicle make and model, labor rates, and the extent of the damage. Here’s a detailed breakdown of ECM repair and replacement costs:

ECM Repair Costs

Repairing an ECM is possible if the damage is limited to components like sensors or minor software glitches. ECM repair costs can range from $300 to $800, depending on the nature of the issue. Labor charges and diagnostic fees may also apply.

ECM Replacement Costs

If the ECM is severely damaged and cannot be repaired, replacement is necessary. Replacing an ECM can be costly, with prices ranging between $500 to $1,500, including parts and labor. The exact cost will depend on the vehicle make and model, as ECMs are specific to each type of car.

Reprogramming the ECM

In some cases, replacing the ECM will require reprogramming it to communicate with the vehicle’s sensors and actuators. Reprogramming fees may range from $80 to $200, depending on the complexity and dealership rates.

Preventing ECM Problems

While ECM failures can sometimes be unpredictable, there are a few steps you can take to prevent common problems:

- Regular Maintenance: Keeping up with regular vehicle maintenance, including oil changes, checking the electrical system, and ensuring proper sensor function, can prevent ECM issues.

- Avoid Water Exposure: Ensure that the ECM is protected from moisture by regularly inspecting seals and gaskets in the engine compartment.

- Check Electrical Systems: Periodically inspect the vehicle’s wiring, battery, and alternator to avoid power surges that could damage the ECM.

- Replace Faulty Sensors Promptly: Replacing faulty sensors at the first sign of trouble can prevent the ECM from receiving incorrect data, which could lead to malfunctions.

Frequently Asked Questions

Here are some FAQs about engine control module (ECM) problems –

1. What are the symptoms of a failing ECM?

Common symptoms of a failing ECM include poor engine performance, trouble starting the vehicle, erratic engine behavior, stalling, and the check engine light staying on. A diagnostic scan can help pinpoint ECM issues.

2. Can a car run with a faulty ECM?

While some cars may continue to run with a faulty ECM, performance will be compromised. You may experience engine misfires, reduced fuel efficiency, and trouble starting. In severe cases, the vehicle may not run at all.

3. How long does an ECM last?

An ECM is designed to last the life of the vehicle, but environmental factors such as water exposure, extreme heat, or electrical surges can shorten its lifespan. On average, an ECM may last 100,000 to 150,000 miles or longer with proper care.

4. Can an ECM be repaired, or does it need to be replaced?

In some cases, an ECM can be repaired if the damage is minor or related to software issues. However, if the internal components or circuits are damaged, replacement may be necessary.

5. Is ECM replacement covered by warranty?

ECM replacement is often covered under the vehicle’s powertrain or emissions warranty, especially if the failure occurs early in the vehicle’s life. Check with your manufacturer or dealership for specific warranty details.

Conclusion

The Engine Control Module (ECM) plays a vital role in keeping your vehicle running smoothly, making it crucial to address any ECM issues promptly. Understanding the symptoms, causes, and solutions to ECM problems can help you maintain your vehicle’s performance and avoid costly repairs. By taking preventive measures, staying on top of maintenance, and addressing electrical or sensor issues early, you can ensure the longevity of your vehicle’s ECM.