Exhaust manifold bolts often come loose due to thermal expansion and contraction, engine vibrations, or improper torque during installation. Over time, these factors can cause the bolts to back out, leading to exhaust leaks and performance issues. To prevent this, use proper torque specifications, high-temperature thread lockers, and consider upgrading to more durable bolts or studs designed for high-heat environments.

When it comes to vehicle maintenance, one common issue that can frustrate even the most experienced mechanics and car owners is the problem of exhaust manifold bolts constantly coming loose. These bolts play a critical role in securing the exhaust manifold to the engine’s cylinder head. If they become loose, it can lead to significant performance issues, including exhaust leaks, increased noise, and even engine damage over time.

Contents

Why Do Exhaust Manifold Bolts Keep Coming Loose?

There are several reasons of exhaust manifold bolts keep coming loose, including –

- Thermal Expansion and Contraction One of the primary reasons exhaust manifold bolts come loose is the continuous cycle of heating and cooling. As the engine operates, the exhaust manifold reaches extremely high temperatures. This causes the metal to expand. When the engine cools down, the metal contracts. Over time, this repeated expansion and contraction can cause the bolts to loosen.

- Vibration The vibrations generated by the engine, especially in high-performance or off-road vehicles, can also contribute to the loosening of manifold bolts. When combined with the heat-induced expansion and contraction, vibrations can gradually back the bolts out of their threaded holes.

- Improper Torque Installing exhaust manifold bolts without tightening them to the manufacturer’s recommended torque specification can lead to issues. Bolts that are too loose won’t hold under the stress, while bolts that are too tight can stretch and weaken, increasing the likelihood of them backing out.

- Corrosion and Rust Exhaust systems are constantly exposed to moisture and other corrosive elements, which can cause bolts to rust. Corrosion weakens the bolt and its threads, reducing the friction that keeps the bolt in place. Once rust has eaten away at the bolt’s surface, it’s more likely to come loose over time.

- Gasket Failure The gasket between the exhaust manifold and the cylinder head plays a critical role in sealing the connection. If the gasket fails or becomes damaged, it can cause uneven pressure on the bolts, making them more prone to loosening.

- Bolt Stretch or Fatigue Exhaust manifold bolts are subject to extreme forces, and over time, they can stretch or experience metal fatigue. This weakens the bolt, reducing its clamping force, and eventually leads to the bolt backing out of the manifold.

How to Fix Exhaust Manifold Bolts Coming Loose Issue

To fix the issue follow the guide below –

- Re-Torquing the Bolts One of the simplest solutions is to periodically check and re-torque the exhaust manifold bolts. Using a torque wrench, ensure the bolts are tightened to the manufacturer’s specifications. Be sure to do this when the engine is cold to avoid over-tightening due to thermal expansion.

- Use of High-Temperature Thread Lockers Thread lockers, such as Loctite, are adhesives designed to prevent bolts from loosening due to vibrations. For exhaust manifold bolts, you need a high-temperature thread locker that can withstand the extreme heat generated by the engine.

- Locking Tab Washers Another option is to use locking tab washers, which can help secure the bolts in place. These washers are designed to prevent rotation, even under high-vibration conditions.

- Replace Worn or Damaged Bolts If the bolts have become corroded or fatigued, they should be replaced with high-quality, heat-resistant bolts. Some manufacturers offer upgraded manifold bolts made from stronger materials that are less prone to stretching or corrosion.

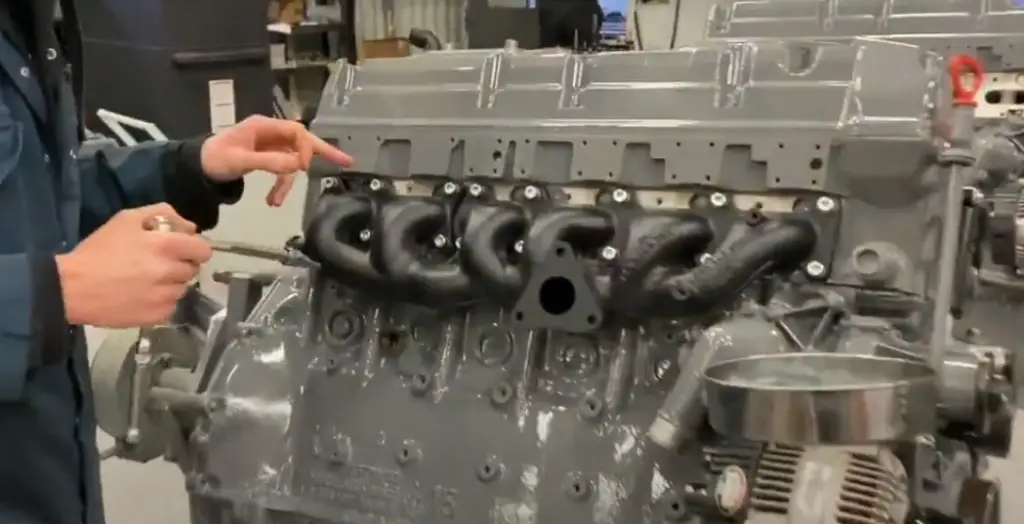

- Install Exhaust Manifold Studs Replacing bolts with exhaust manifold studs can provide a more secure solution. Studs are installed into the cylinder head, and nuts are used to fasten the manifold to the studs. This setup tends to be more resistant to loosening because the stud threads into the head more securely than bolts, and the nut can be torqued down to the correct specification.

- Inspect and Replace the Exhaust Manifold Gasket If the gasket is worn, damaged, or improperly installed, it can place uneven pressure on the manifold bolts, leading to loosening. Inspect the gasket for wear, and replace it if necessary. Be sure to choose a high-quality gasket that can withstand extreme temperatures and pressure.

- Regular Maintenance and Inspections Regularly inspecting the exhaust manifold and bolts as part of your vehicle’s maintenance routine can prevent problems before they escalate. Early detection of issues such as rust, loose bolts, or gasket failure will help you address the problem before it causes significant damage.

How to prevent Exhaust Manifold Bolts from Coming Loose

To prevent the problem follow the instruction below –

- Proper Torque Settings Always ensure that the exhaust manifold bolts are torqued to the manufacturer’s specifications. Using a torque wrench is critical for accuracy. Over-tightening or under-tightening can lead to issues with bolts coming loose.

- Heat Shields and Insulation Installing heat shields or thermal wraps around the exhaust manifold can help reduce the extreme temperatures that contribute to bolt loosening. By minimizing the heat cycling, you can extend the life of both the manifold and its bolts.

- Upgrade to High-Quality Fasteners Standard exhaust manifold bolts may not always be up to the task, especially in high-performance or heavy-duty applications. Upgrading to high-strength fasteners made from materials such as Inconel or titanium can provide better resistance to thermal expansion, stretching, and corrosion.

- Vibration Dampeners If your vehicle experiences excessive vibration, consider installing engine or exhaust vibration dampeners. These devices help reduce vibrations that can cause bolts to loosen over time.

- Regular Re-Tightening Schedule Even with the best installation practices, it’s a good idea to check the torque on your exhaust manifold bolts periodically, especially after hard driving or significant engine work. A regular re-tightening schedule can prevent bolts from loosening due to thermal cycling and vibration.

Related Article

Why Do Exhaust Manifold Bolts Break?

How to Remove Exhaust Manifold Bolts

Stripped Exhaust Manifold Bolt Holes

Are Exhaust Manifold Bolts Special?

Frequently Asked Questions

Here are some FAQs about exhaust manifold bolts –

Why do my exhaust manifold bolts keep coming loose?

The most common reasons for exhaust manifold bolts coming loose include thermal expansion and contraction, engine vibrations, improper torque settings, corrosion, and gasket failure.

Can I use a thread locker on exhaust manifold bolts?

Yes, you can use a high-temperature thread locker on exhaust manifold bolts to prevent them from loosening. Ensure that the product you choose is rated for the extreme temperatures encountered in exhaust systems.

How often should I check my exhaust manifold bolts?

It’s a good practice to check your exhaust manifold bolts during routine vehicle maintenance or after any significant engine work. For high-performance or off-road vehicles, more frequent checks may be necessary due to increased stress on the exhaust system.

What happens if I don’t fix loose exhaust manifold bolts?

If loose exhaust manifold bolts are not addressed, they can lead to exhaust leaks, increased noise, reduced engine performance, and potentially more severe damage to the cylinder head or exhaust system over time.

Should I replace the gasket if my manifold bolts are loose?

It’s a good idea to inspect the exhaust manifold gasket if the bolts are coming loose. A damaged or worn gasket can place uneven pressure on the bolts, contributing to the problem. If the gasket shows signs of wear, it should be replaced.

Conclusion

Exhaust manifold bolts coming loose is a problem that can have significant consequences if not addressed. Understanding the causes and implementing the right solutions, such as re-torquing bolts, using thread lockers, and upgrading to higher-quality fasteners, can help keep your exhaust manifold secure. By incorporating preventative measures like proper torque, regular inspections, and addressing vibration issues, you can reduce the likelihood of facing this issue again in the future.