Exhaust pipe wall thickness, usually 1.2–3 mm, impacts durability, heat resistance, and performance. Thicker pipes are stronger but heavier, while thinner ones are lighter but less durable. The ideal thickness depends on the vehicle type and usage.

The exhaust system in a vehicle plays a crucial role in controlling emissions, enhancing performance, and ensuring smooth engine operation. One often overlooked but critical aspect of this system is the wall thickness of the exhaust pipe. The thickness of exhaust pipes impacts their durability, performance, and the overall efficiency of the exhaust system.

In this blog, we will explore the importance of exhaust pipe wall thickness, factors influencing its selection, typical standards, materials used, and considerations for choosing the right thickness for specific applications.

Contents

- 1 What Is Exhaust Pipe Wall Thickness?

- 2 Importance of Exhaust Pipe Wall Thickness

- 3 Factors Influencing Exhaust Pipe Wall Thickness

- 4 Industry Standards and Measurements

- 5 Pros and Cons of Different Wall Thicknesses

- 6 Considerations for Choosing the Right Wall Thickness

- 7 Frequently Asked Questions

- 8 Conclusion

What Is Exhaust Pipe Wall Thickness?

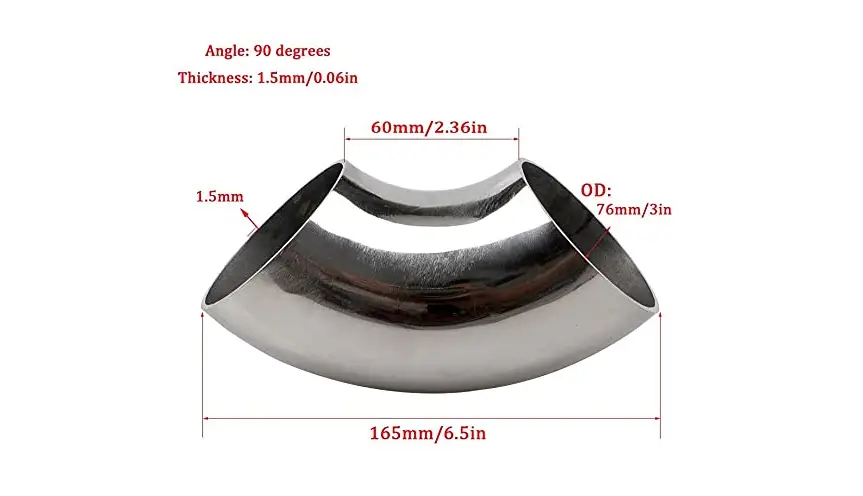

Exhaust pipe wall thickness refers to the thickness of the metal used to construct the pipes in a vehicle’s exhaust system. It is usually measured in millimeters (mm) or inches and varies depending on the type of vehicle, exhaust system design, and intended use. Commonly, the wall thickness ranges between 1.2 mm to 3 mm (0.047–0.118 inches), though specialized systems might use thicker or thinner pipes.

Importance of Exhaust Pipe Wall Thickness

Exhaust pipe wall thickness plays a critical role in the performance, durability, and safety of a vehicle’s exhaust system. Here’s why it is important:

1. Durability and Longevity

Thicker pipes are more resistant to external damage, corrosion, and wear. They can withstand higher temperatures and vibrations, making them suitable for heavy-duty or high-performance applications.

2. Thermal and Acoustic Insulation

The thickness of an exhaust pipe can influence its thermal and acoustic properties. Thicker walls tend to absorb and retain heat better, reducing external heat dissipation. This property is especially beneficial in maintaining exhaust gas temperatures, improving catalytic converter efficiency, and reducing noise levels.

3. Weight Considerations

While thicker pipes are more robust, they also add weight to the vehicle. In applications where weight reduction is critical, such as racing or aerospace, thinner pipes are preferred, provided they meet structural and thermal requirements.

4. Performance Implications

Wall thickness affects the flow of exhaust gases. Pipes that are too thick may disrupt the internal flow due to uneven heating or distortion under thermal stress. On the other hand, pipes that are too thin may fail under high pressure or repeated thermal cycles.

Factors Influencing Exhaust Pipe Wall Thickness

Several factors influence the optimal wall thickness of exhaust pipes. These considerations ensure the exhaust system balances durability, weight, performance, and cost. Here’s a breakdown of the most significant factors:

1. Vehicle Type and Use

- Passenger Cars: Standard passenger vehicles typically use pipes with a thickness of 1.2–2 mm to balance cost, performance, and durability.

- Commercial Vehicles: Trucks and heavy machinery often use thicker pipes (2–3 mm) to handle higher loads and harsh conditions.

- High-Performance Vehicles: Racing cars and performance vehicles may use specialized pipes with optimized thickness to reduce weight without compromising performance.

2. Material Used

The material of the exhaust pipe significantly impacts the required wall thickness:

- Mild Steel: Requires thicker walls due to lower resistance to corrosion and heat.

- Stainless Steel: Often used in 1.2–2 mm thickness, as it provides superior resistance to corrosion and high temperatures.

- Aluminized Steel: Offers a balance of cost and performance, with wall thickness similar to stainless steel.

- Titanium and Inconel: High-performance materials that allow for thinner walls due to their strength-to-weight ratio.

3. Environmental Conditions

Vehicles operating in harsh environments (e.g., off-road or coastal areas) may require thicker walls to withstand exposure to salt, debris, and extreme temperatures.

4. Exhaust System Design

Complex systems with bends and joints may require pipes with greater wall thickness to maintain structural integrity under thermal and mechanical stress.

Industry Standards and Measurements

Exhaust pipe wall thickness is standardized across the automotive industry to ensure safety, durability, and performance. These standards are based on factors like material type, vehicle application, and regulatory compliance. Here’s a comprehensive look at the common industry standards and typical measurements:

Common Standards

- SAE (Society of Automotive Engineers) and ASTM (American Society for Testing and Materials) set guidelines for exhaust pipe materials and thickness.

- Typical recommendations suggest 1.5 mm for standard applications and 2.0–3.0 mm for heavy-duty use.

Measuring Wall Thickness

Wall thickness is measured using calipers or ultrasonic thickness gauges. Regular measurement is crucial in maintenance to identify thinning due to corrosion or wear.

Pros and Cons of Different Wall Thicknesses

The wall thickness of an exhaust pipe significantly impacts its performance, durability, and cost. Below is a detailed look at the pros and cons of using thinner and thicker wall exhaust pipes:

| Wall Thickness | Advantages | Disadvantages |

|---|---|---|

| Thin (1.0–1.5 mm) | Lightweight, cost-effective, suitable for low-stress applications. | Less durable, prone to deformation and corrosion. |

| Moderate (1.5–2.5 mm) | Balanced durability and performance, ideal for most vehicles. | Slightly heavier, higher cost than thinner pipes. |

| Thick (2.5–3.0 mm) | Maximum durability, resistant to extreme conditions. | Heavy, expensive, may reduce fuel efficiency. |

Considerations for Choosing the Right Wall Thickness

Choosing the right wall thickness for an exhaust pipe involves balancing performance, durability, cost, and application-specific requirements. Below are the key considerations to help make the best choice:

- Application Requirements: Consider the type of vehicle, its usage, and the expected lifespan of the exhaust system.

- Budget: Thicker pipes generally cost more due to higher material usage.

- Weight Constraints: Thicker pipes add weight, which can impact fuel efficiency and vehicle dynamics.

- Material Choice: High-strength materials like stainless steel or titanium may allow for reduced thickness without compromising durability.

- Customization Needs: For custom exhaust systems, consulting with professionals or manufacturers ensures the best fit for your specific requirements.

Related Article

Exhaust Pipe Paint

Water in Exhaust Pipe

How To Weld Exhaust Pipe

Frequently Asked Questions

Here are some FAQs about exhaust pipe wall thickness –

1. What is the standard exhaust pipe wall thickness for most passenger cars?

The standard wall thickness for passenger cars typically ranges from 1.5 mm to 2 mm, depending on the material used and design requirements.

2. How does wall thickness affect exhaust system performance?

Wall thickness influences durability, thermal insulation, noise reduction, and the overall weight of the exhaust system. Thicker pipes improve durability but may add weight, whereas thinner pipes are lighter but less durable.

3. Can I use thinner exhaust pipes for a high-performance car?

Yes, but the choice of material is critical. High-strength materials like titanium or Inconel can compensate for reduced thickness while maintaining performance and durability.

4. How can I measure the wall thickness of an exhaust pipe?

You can measure wall thickness using calipers for accessible sections or ultrasonic thickness gauges for a non-invasive method.

5. What is the best material for exhaust pipes in terms of wall thickness?

Stainless steel is one of the best materials due to its balance of strength, corrosion resistance, and heat tolerance. For high-performance applications, titanium or Inconel is preferred due to their superior strength-to-weight ratios.

Conclusion

The wall thickness of an exhaust pipe plays a pivotal role in the durability, performance, and efficiency of an exhaust system. While there is no one-size-fits-all solution, understanding the factors that influence the selection of wall thickness—such as material, application, and environmental conditions—can help ensure optimal performance.

Whenever you’re designing a custom exhaust system or maintaining a factory-installed one, paying attention to pipe wall thickness is essential for long-term reliability and efficiency.

If you’re unsure about what wall thickness suits the vehicle, consult with an automotive specialist or exhaust system manufacturer to make an informed decision.