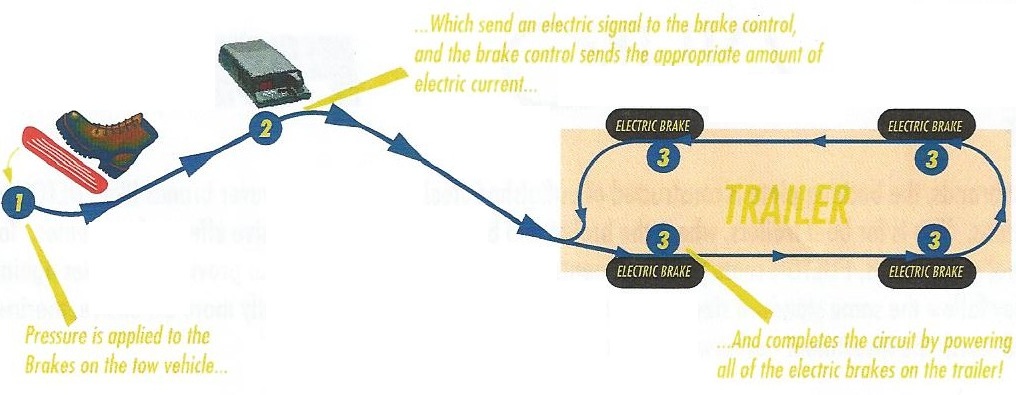

Electric trailer brakes work when the brake pedal in the towing vehicle sends an electrical signal to the brake controller, which then activates the trailer brakes. The brake controller regulates the braking force applied to the trailer’s wheels, helping to slow down the entire rig smoothly and safely.

Towing a trailer, whether it’s for recreational purposes, work, or transportation, requires an added layer of control and safety. One of the most critical components for safely towing trailers is the braking system. Electric trailer brakes are a popular choice for many trailer owners due to their efficiency, responsiveness, and ease of integration with modern vehicles.

Understanding how electric trailer brakes work is crucial for anyone who regularly tows trailers, as it ensures safer and more efficient braking performance.

Contents

What Are Electric Trailer Brakes?

Electric trailer brakes are braking systems that use electrical power to engage the trailer’s brakes. Unlike hydraulic brakes that rely on fluid pressure, electric brakes use electromagnetic force to provide stopping power. This allows the brakes to be directly controlled by the driver via an electric brake controller installed in the towing vehicle.

Electric brakes are commonly found on trailers designed for heavy loads, such as travel trailers, cargo trailers, and horse trailers. They offer greater control and braking precision, especially when used in conjunction with the vehicle’s brake system.

Key Components of Electric Trailer Brakes

To understand how electric trailer brakes work, it’s important to know the major components involved in the system:

- Brake Controller: This device is installed in the towing vehicle and controls the activation of the trailer’s electric brakes. The brake controller senses the braking intensity of the vehicle and sends the corresponding electrical signal to the trailer’s brakes.

- Brake Magnets: The electric brake system uses brake magnets to create the necessary force to engage the brakes. When power is applied to the magnets, they generate a magnetic field that pulls on a rotating drum (the brake drum), applying pressure to brake shoes or pads.

- Brake Shoes: Brake shoes are curved pieces of metal with a friction material lining that presses against the brake drum to create friction and slow down the wheel. When the brake magnets engage, the brake shoes expand outward, pressing against the drum and causing the trailer to slow down.

- Brake Drum: The brake drum is a cylindrical component that rotates with the trailer’s wheel. When the brake shoes press against the inner surface of the drum, the friction slows the wheel down, ultimately bringing the trailer to a stop.

- Wiring Harness: This set of electrical wires connects the brake controller in the towing vehicle to the electric brakes on the trailer. It carries the signals and power needed to activate the brakes.

- Breakaway Switch: In case the trailer disconnects from the towing vehicle while in motion, the breakaway switch activates the trailer brakes to prevent uncontrolled movement. This is a vital safety feature for preventing runaway trailers.

How Electric Trailer Brakes Work

The operation of electric trailer brakes is a relatively simple process, but it is highly effective for towing heavy loads. Here’s a step-by-step breakdown of how they work:

1. Brake Controller Activation

The brake controller installed in the towing vehicle is connected to the trailer via the wiring harness. When the driver applies the vehicle’s brakes, the brake controller detects the force applied through the brake pedal. Depending on the type of brake controller (proportional or time-delayed), the controller will either match the force of the vehicle’s brakes or apply a pre-set braking force to the trailer brakes.

2. Electrical Signal Sent to the Trailer

Once the brake controller senses braking, it sends an electrical signal to the trailer’s brakes. This signal is transmitted through the wiring harness and reaches the brake magnets located inside the trailer’s braking system.

3. Magnetic Force Engages the Brakes

The brake magnets are the heart of the electric trailer brake system. When they receive the electrical current from the brake controller, the magnets create a strong magnetic field. This field pulls on the armature, which causes the brake shoes to press outward against the rotating brake drum.

4. Friction Slows the Trailer

As the brake shoes press against the inside of the drum, friction is created between the two surfaces. This friction slows the rotation of the drum and, consequently, the trailer’s wheels. The more braking force applied by the controller, the harder the brake shoes press against the drum, increasing the braking power.

5. Stopping the Trailer

The electric trailer brake system works in tandem with the towing vehicle’s brakes. The amount of braking applied to the trailer can be adjusted using the brake controller, allowing the driver to balance the braking forces between the trailer and the vehicle. This ensures smooth, controlled stops, even when hauling heavy loads.

Credit: www.hitchweb.com

Types of Electric Trailer Brake Controllers

The brake controller plays a critical role in managing the trailer’s braking system. There are two primary types of brake controllers: proportional and time-delayed.

1. Proportional Brake Controllers

Proportional brake controllers, also known as inertia-based controllers, offer more precise control by sensing the deceleration of the towing vehicle. They apply the same amount of braking force to the trailer’s brakes as the towing vehicle’s brakes. This results in smoother stops and better coordination between the vehicle and trailer, particularly during emergency braking situations.

2. Time-Delayed Brake Controllers

Time-delayed brake controllers, on the other hand, work by applying a pre-set amount of braking force to the trailer brakes regardless of the towing vehicle’s deceleration. The braking force is applied after a short delay, which can be adjusted by the driver. While more affordable and easier to install than proportional controllers, time-delayed controllers offer less precise braking and may result in jerky stops or uneven braking distribution.

Importance of Maintaining Electric Trailer Brakes

Proper maintenance of your electric trailer brakes is essential for safe towing. Here are some key maintenance tips:

- Check the Brake Controller: Regularly test the brake controller to ensure it’s properly calibrated and delivering the right amount of braking force. If the controller is not working correctly, it can lead to over-braking or under-braking.

- Inspect Brake Magnets: The brake magnets should be checked periodically for wear. If the magnets are damaged or excessively worn, they may not generate enough force to properly engage the brakes.

- Examine Brake Shoes and Drums: Just like the brakes on your vehicle, the brake shoes and drums on your trailer wear down over time. Regularly inspect these components for signs of wear or damage and replace them when necessary.

- Check Wiring Connections: Ensure that the wiring harness connecting the trailer to the vehicle is in good condition and free from corrosion or fraying. Damaged wiring can lead to poor brake performance or complete failure.

- Test the Breakaway Switch: The breakaway switch should be tested regularly to ensure it functions correctly in case of an emergency.

Frequently Asked Questions

Here are some FAQs about electric trailer brakes –

1. Do all trailers have electric brakes?

No, not all trailers come equipped with electric brakes. Smaller trailers may use mechanical or hydraulic braking systems, while larger trailers designed for heavy loads are more likely to have electric brakes. Many states and provinces require trailers over a certain weight to be equipped with their own braking systems.

2. Do I need a brake controller to use electric trailer brakes?

Yes, a brake controller is necessary to operate electric trailer brakes. Without a brake controller, there is no way to send the electrical signal from the towing vehicle to the trailer’s brakes. The brake controller allows the driver to adjust the braking force applied to the trailer for smooth, controlled stops.

3. What is the difference between electric brakes and surge brakes?

Electric brakes rely on an electrical signal from the towing vehicle’s brake controller, while surge brakes are hydraulic and operate based on the trailer’s forward momentum. Surge brakes don’t require a brake controller but are less responsive and harder to adjust than electric brakes.

4. Can I adjust the braking power of my electric trailer brakes?

Yes, the braking power of electric trailer brakes can be adjusted using the brake controller. Proportional controllers automatically adjust braking power based on vehicle deceleration, while time-delayed controllers allow the driver to manually set the amount of braking force applied to the trailer.

5. How often should I service my electric trailer brakes?

It’s recommended to service electric trailer brakes every 12,000 miles or once a year, whichever comes first. However, if you frequently tow heavy loads or drive in harsh conditions, more frequent inspections and servicing may be necessary.

Conclusion

Electric trailer brakes are a crucial component for towing safety, providing effective braking power for trailers of all sizes. By understanding how they work and ensuring they are properly maintained, you can tow confidently, knowing your trailer will stop smoothly and safely every time. Whether you’re towing a lightweight camper or a heavy-duty cargo trailer, electric brakes offer the precision and control necessary for a safe and stress-free towing experience.