The intake manifold directs the air-fuel mixture from the throttle body to the engine’s cylinders, ensuring each cylinder receives an equal amount for balanced combustion. It consists of a plenum and runners that distribute this mixture efficiently. Proper functioning of the intake manifold is essential for smooth engine performance, optimal power output, and fuel efficiency.

The intake manifold is a critical component of an internal combustion engine, playing a pivotal role in ensuring that your engine runs efficiently and smoothly. Despite its significance, it often goes unnoticed until a problem arises. Understanding how the intake manifold works is essential for anyone interested in automotive mechanics or seeking to optimize their vehicle’s performance.

Contents

What is the Intake Manifold?

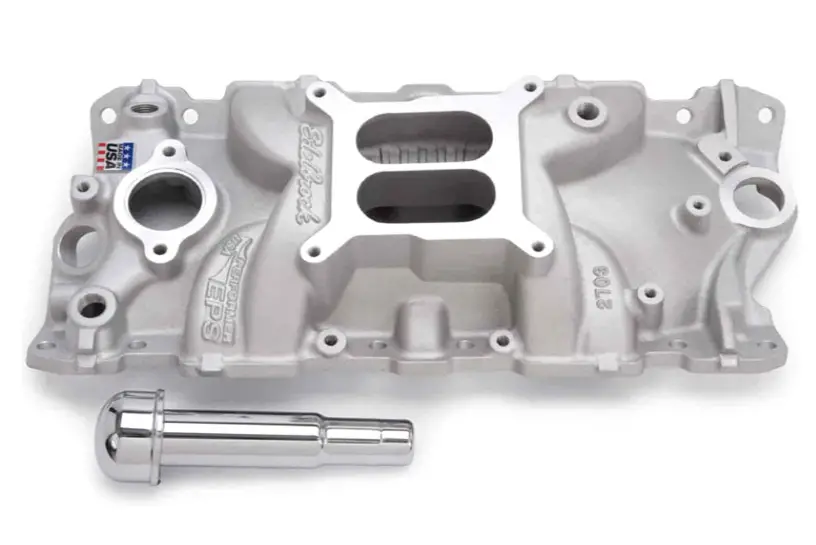

The intake manifold is a system of passages that directs the air-fuel mixture from the throttle body to the engine’s cylinders. It is typically made of aluminum, plastic, or a combination of both, depending on the design and requirements of the engine. The manifold ensures that each cylinder receives an equal amount of air-fuel mixture, which is crucial for balanced combustion and optimal engine performance.

The Role of the Intake Manifold in the Engine

The primary function of the intake manifold is to evenly distribute the air-fuel mixture to each cylinder. This process begins when air enters the engine through the air filter, passes through the throttle body, and enters the intake manifold. The manifold then channels this air, mixing it with fuel (in fuel-injected engines) before it reaches the intake valves of each cylinder.

This even distribution is vital for several reasons:

- Balanced Combustion: For the engine to run smoothly, each cylinder must receive an equal amount of the air-fuel mixture. Any imbalance can lead to rough idling, misfires, or even engine damage.

- Optimal Power Output: A consistent air-fuel mixture ensures that each cylinder produces the same amount of power, leading to smoother acceleration and better overall performance.

- Efficient Fuel Consumption: By providing each cylinder with the correct amount of air and fuel, the intake manifold helps optimize fuel efficiency, reducing waste and emissions.

Components of the Intake Manifold

Understanding the various components of the intake manifold can help clarify how it performs its crucial functions. Here are the key parts:

- Plenum: The plenum is the central chamber in the intake manifold where air accumulates after passing through the throttle body. It acts as a reservoir, ensuring that a sufficient volume of air is available to be distributed to the cylinders.

- Runners: These are the individual passages that connect the plenum to each cylinder. The length and diameter of the runners are carefully engineered to optimize air flow and ensure that each cylinder receives the correct amount of air.

- Gaskets: The intake manifold is sealed to the engine block using gaskets, which prevent air and fuel from leaking out. These gaskets must maintain a tight seal to ensure that the engine runs efficiently.

- Throttle Body: Although not technically a part of the intake manifold, the throttle body is closely related. It regulates the amount of air entering the intake manifold and, consequently, the engine.

- Intake Valves: These valves are located at the end of each runner and control the timing and amount of air-fuel mixture that enters the cylinder. They play a crucial role in the engine’s combustion process.

How the Intake Manifold Operates

The operation of the intake manifold is closely tied to the engine’s four-stroke cycle: intake, compression, power, and exhaust. Here’s a step-by-step breakdown of how the intake manifold works during each phase:

- Intake Stroke: As the piston moves downwards in the cylinder, the intake valve opens, creating a vacuum that draws the air-fuel mixture from the intake manifold into the cylinder. The manifold ensures that the mixture is evenly distributed and enters the cylinder smoothly.

- Compression Stroke: The intake valve closes, and the piston moves upward, compressing the air-fuel mixture. This compression is crucial for generating the power needed to propel the vehicle.

- Power Stroke: The compressed air-fuel mixture is ignited by a spark plug, causing an explosion that forces the piston downward. This movement generates the power that drives the engine.

- Exhaust Stroke: The exhaust valve opens, and the piston moves upward again, pushing the burnt gases out of the cylinder and into the exhaust manifold. The cycle then repeats.

Throughout these stages, the intake manifold ensures that the air-fuel mixture is delivered efficiently and consistently to each cylinder, enabling the engine to produce power smoothly and effectively.

Types of Intake Manifolds

There are several different designs of intake manifolds, each tailored to specific engine configurations and performance needs:

- Single Plane Manifold: Also known as a “360-degree” manifold, this design has a single large plenum that feeds all the cylinders. It is often used in high-performance engines because it allows for better airflow at high RPMs.

- Dual Plane Manifold: This manifold has two separate plenums, each feeding a different set of cylinders. It is designed for low to mid-RPM ranges, providing better torque and smoother acceleration.

- Tuned Port Injection (TPI) Manifold: This design uses long runners to improve torque at low RPMs. It is common in engines designed for fuel efficiency and smooth power delivery.

- Variable Intake Manifold: Some modern engines use variable intake manifolds that can adjust the length of the runners based on engine speed. This allows for optimized performance across a wide range of RPMs.

Common Issues with Intake Manifolds

While the intake manifold is a robust component, it is not immune to problems. Common issues include:

- Vacuum Leaks: Over time, the gaskets that seal the intake manifold can deteriorate, leading to vacuum leaks. This can cause rough idling, poor fuel economy, and even engine stalling.

- Carbon Build-Up: Carbon deposits can accumulate inside the intake manifold, restricting airflow and reducing engine performance. Regular cleaning can help mitigate this issue.

- Cracks or Warping: In some cases, the intake manifold itself can crack or warp due to heat and pressure. This can lead to air leaks and poor engine performance.

- Coolant Leaks: In some engines, the intake manifold also routes coolant. A damaged manifold can cause coolant leaks, leading to overheating and potential engine damage.

Maintenance Tips for the Intake Manifold

Proper maintenance of the intake manifold can prolong its lifespan and ensure your engine runs efficiently. Here are some tips:

- Regular Inspection: Periodically inspect the intake manifold and its gaskets for signs of wear or damage. Address any issues promptly to prevent further damage.

- Cleaning: Carbon build-up can be mitigated by using a fuel system cleaner or by manually cleaning the intake manifold. This should be done regularly, especially in high-mileage vehicles.

- Gasket Replacement: If you notice signs of a vacuum or coolant leak, replace the intake manifold gaskets as soon as possible to prevent further damage.

- Check for Cracks: Inspect the manifold for cracks or warping, especially if you experience performance issues or coolant leaks. Replace the manifold if necessary.

Frequently Asked Questions

Here are some FAQs about the intake manifold performance –

1. How does the intake manifold affect engine performance?

The intake manifold plays a critical role in engine performance by ensuring that each cylinder receives an equal and consistent amount of air-fuel mixture. This balance is essential for smooth operation, optimal power output, and fuel efficiency.

2. Can a damaged intake manifold cause engine misfires?

Yes, a damaged intake manifold, particularly if it has a vacuum leak, can cause engine misfires. This is because the air-fuel mixture may become unbalanced, leading to incomplete combustion in one or more cylinders.

3. How can I tell if my intake manifold is leaking?

Common symptoms of an intake manifold leak include rough idling, poor fuel economy, engine stalling, and a check engine light. You may also notice a hissing sound coming from the engine bay.

4. Is it possible to repair a cracked intake manifold?

In some cases, a cracked intake manifold can be repaired using specialized sealants or by welding. However, it is often more reliable to replace the manifold, especially if the damage is extensive.

5. How often should the intake manifold be cleaned?

The frequency of cleaning depends on your vehicle’s usage and condition. For most vehicles, cleaning the intake manifold every 30,000 to 50,000 miles is recommended, or sooner if you notice performance issues.

Conclusion

The intake manifold is a vital component of an internal combustion engine, playing a crucial role in delivering the air-fuel mixture to the cylinders. By understanding how it works, you can better appreciate its importance and take steps to maintain it, ensuring your engine runs smoothly and efficiently. Regular inspection, cleaning, and prompt repairs can extend the life of your intake manifold and contribute to the overall health of your engine.