Internal combustion engines are an integral part of many machines we encounter daily, from cars and motorcycles to lawn equipment and chainsaws. Among the most common types of these engines is the 2-cycle engine, also known as a 2-stroke engine. These engines are distinct from their 4-stroke counterparts due to their simpler design, smaller size, and unique operation.

One of the most frequently asked questions about 2-cycle engines is, “How many strokes does a 2-cycle engine have?” In this detailed blog post, we will explore what a stroke means in the context of an engine, how a 2-cycle engine operates, and why this engine type is often favored in certain applications.

By the end, you’ll have a clear understanding of how 2-cycle engines work, what makes them different from other engines, and why they remain popular in specific uses despite being less common in vehicles today.

Contents

Engine Strokes

To understand the concept of strokes in a 2-cycle engine, let’s first break down what a stroke is in internal combustion engines.

A stroke refers to the movement of the piston in the cylinder of an engine. In any internal combustion engine, the piston moves up and down inside the cylinder to create mechanical energy. Each complete movement of the piston in one direction is called a stroke. In a traditional engine, this movement is used to:

- Compress fuel and air to create combustion.

- Expel exhaust gases after combustion.

In a 2-cycle engine, as the name suggests, there are only two strokes involved in a full cycle of combustion and power production, which sets it apart from the 4-stroke engine.

How a 2-Cycle Engine Operates

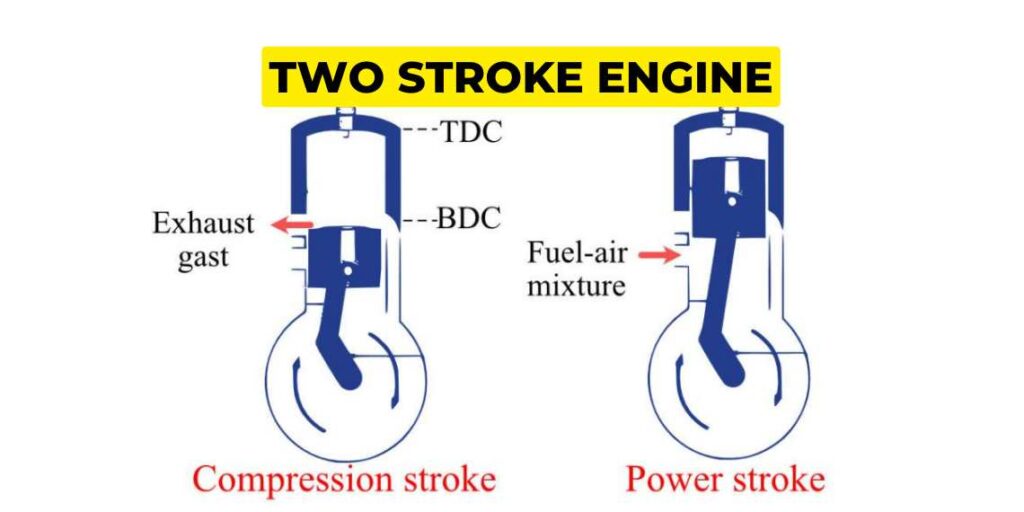

The 2-cycle engine completes its power generation process in just two strokes:

1. First Stroke: Combustion and Exhaust

- Compression: In the first stroke, the piston moves upward in the cylinder, compressing a mixture of fuel and air that was introduced earlier. This compression increases the pressure and temperature of the fuel-air mixture, preparing it for combustion.

- Ignition and Power: When the piston reaches the top of the cylinder, a spark plug ignites the compressed fuel-air mixture. The resulting explosion forces the piston back down, generating power that moves the vehicle or machine forward. This downward movement is the start of the second part of the first stroke.

- Exhaust: As the piston moves down, it uncovers an exhaust port, allowing the burnt gases from combustion to exit the cylinder. This is the second major task of the first stroke: getting rid of waste gases.

2. Second Stroke: Intake and Compression

- Scavenging: While the piston continues its downward motion after combustion, it also uncovers intake ports. These allow a fresh mixture of air and fuel to be drawn into the cylinder as the burnt exhaust gases leave through the exhaust port. This process is called scavenging, where new air-fuel replaces the old gases.

- Compression (again): As the piston moves back upward to complete the second stroke, it compresses the newly introduced air-fuel mixture, preparing it for the next combustion cycle.

And just like that, with only two strokes—one upward and one downward—the engine has completed a full combustion cycle and is ready to start again. This simplicity makes 2-cycle engines much smaller and lighter compared to 4-stroke engines, which require four separate strokes for the same process (intake, compression, power, and exhaust).

Why 2 Cycle Engines Are Used

2-cycle engines have some distinct advantages that make them useful in specific applications:

1. Simplicity and Lightweight Design

With fewer moving parts, 2-cycle engines are typically smaller and lighter than 4-stroke engines. This makes them ideal for handheld devices like chainsaws, leaf blowers, and motorcycles, where weight is a critical factor. Fewer parts also mean there’s less that can go wrong mechanically, resulting in easier maintenance and less frequent repairs.

2. Higher Power-to-Weight Ratio

Because 2-cycle engines produce a power stroke every revolution of the crankshaft (as opposed to every two revolutions in a 4-stroke engine), they can generate more power relative to their size. This gives them a better power-to-weight ratio, making them more efficient for high-demand tasks like off-road biking or powering small equipment.

3. Simple Lubrication

2-cycle engines typically mix oil with fuel, which lubricates the engine as it runs. This eliminates the need for a separate lubrication system like the one in 4-stroke engines, further simplifying the engine’s design.

4. Cost-Effectiveness

Due to their simpler design and fewer parts, 2-cycle engines are often cheaper to manufacture and repair, making them a cost-effective choice for many small engine applications.

Disadvantages of 2-Cycle Engines

Despite their advantages, 2-cycle engines also come with some significant drawbacks, which is why they’ve largely been replaced by 4-stroke engines in modern vehicles.

1. Less Fuel-Efficient

Due to their simplistic design and lack of precise control over fuel intake, 2-cycle engines tend to burn more fuel than 4-stroke engines. This makes them less fuel-efficient, especially in applications requiring long-term operation.

2. Higher Emissions

Because of the way fuel and oil are mixed and combusted in a 2-cycle engine, these engines produce more emissions compared to their 4-stroke counterparts. Unburnt fuel can escape through the exhaust during scavenging, contributing to pollution. This is one of the main reasons 2-stroke engines are being phased out in many countries with strict emissions regulations.

3. Shorter Lifespan

The continuous combustion process in a 2-cycle engine generates more heat and wear on engine components, which can reduce the overall lifespan of the engine compared to a 4-stroke engine. Additionally, the lack of a separate lubrication system means that 2-cycle engines may not be as well-protected against wear and tear.

Comparison Between 2-Cycle and 4-Cycle Engines

To better understand the differences, let’s compare the 2-cycle and 4-cycle engines side by side:

| Feature | 2-Cycle Engine | 4-Cycle Engine |

|---|---|---|

| Number of Strokes | 2 strokes (up and down) | 4 strokes (intake, compression, power, exhaust) |

| Power Generation | Power stroke every revolution of the crankshaft | Power stroke every two revolutions of the crankshaft |

| Size and Weight | Smaller, lighter | Larger, heavier |

| Fuel Efficiency | Less fuel-efficient | More fuel-efficient |

| Emissions | Higher emissions | Lower emissions |

| Lubrication | Oil mixed with fuel | Separate lubrication system |

| Maintenance | Simple, fewer parts | More parts, more complex maintenance |

| Typical Applications | Chainsaws, leaf blowers, motorcycles | Cars, trucks, lawn mowers, generators |

Frequently Asked Questions

Here are some FAQs about 2 cycle engines –

1. Why are 2-cycle engines often used in small equipment?

2-cycle engines are favored in small equipment because they are lightweight, compact, and have fewer moving parts, making them easier to maintain. Their high power-to-weight ratio is ideal for tools like chainsaws and leaf blowers.

2. What type of fuel do 2-cycle engines use?

2-cycle engines typically require a mixture of gasoline and oil. The oil serves as a lubricant for the engine’s internal parts, as 2-cycle engines lack a separate lubrication system.

3. Are 2-cycle engines less fuel-efficient than 4-cycle engines?

Yes, 2-cycle engines tend to be less fuel-efficient because they complete a power stroke every revolution, leading to incomplete combustion and higher fuel consumption. Additionally, some unburnt fuel may escape during the scavenging process.

4. Can a 2-cycle engine run on regular gasoline?

No, 2-cycle engines require a mixture of oil and gasoline to function properly. Using regular gasoline without oil can result in engine failure, as the necessary lubrication for the engine’s moving parts would be absent.

5. Why are 2-cycle engines being phased out in some applications?

Due to their high emissions and inefficiency compared to 4-cycle engines, 2-cycle engines are being phased out in applications where stricter environmental regulations apply, particularly in vehicles and larger machinery.

Conclusion

A 2-cycle engine completes its power generation process in just two strokes: one for combustion and exhaust, and another for intake and compression. This design allows for a simpler, lighter engine with a higher power-to-weight ratio, making it ideal for certain applications.

However, the disadvantages-such as higher emissions and lower fuel efficiency-have led to the decline of 2-cycle engines in many industries. Understanding the strengths and weaknesses of these engines is essential when determining whether they are suitable for your needs.