To bend an exhaust pipe, use a pipe bender and apply steady pressure to avoid kinks. Mark the bend area, and for tough materials, heat the pipe or fill it with sand for support. Always wear safety gear and work carefully for precise results.

When customizing or repairing an exhaust system, bending exhaust pipes is often necessary to achieve the perfect fit. This process requires precision, the right tools, and a good understanding of the materials involved. Whether you’re a DIY enthusiast or a seasoned mechanic, learning how to bend exhaust pipes correctly ensures your system remains efficient and durable.

In this guide, we’ll cover the tools, techniques, and tips for bending exhaust pipes successfully. Additionally, we’ll address common FAQs to help you troubleshoot any issues along the way.

Contents

- 1 Exhaust Pipe Bending

- 2 How to Bend Exhaust Pipe

- 3 Tips for Successful Exhaust Pipe Bending

- 4 Common Challenges and Solutions

- 4.1 1. Kinking or Flattening of the Pipe

- 4.2 2. Cracking or Splitting

- 4.3 3. Misalignment of the Bend

- 4.4 4. Over-Bending

- 4.5 5. Weak Spots at the Bend

- 4.6 6. Uneven Bends

- 4.7 7. Surface Damage

- 4.8 8. Difficulty Bending Thick-Walled or Stainless Steel Pipes

- 4.9 9. Limited Access to Proper Tools

- 4.10 10. Safety Hazards

- 4.11 Safety Precautions

- 5 Frequently Asked Questions

- 6 Conclusion

Exhaust Pipe Bending

Exhaust pipes are typically made from materials like mild steel, aluminized steel, or stainless steel. These metals are durable and corrosion-resistant but can deform or crack if bent improperly. Here’s what you need to know:

- Pipe Size and Thickness: Pipes come in various diameters and thicknesses. Thin-walled pipes are easier to bend but are more prone to kinks.

- Types of Bends: Common bends include 45-degree, 90-degree, and custom angles, depending on the design of the exhaust system.

- Bending Tools: Choosing the right tool is critical for achieving smooth, uniform bends.

How to Bend Exhaust Pipe

Bending an exhaust pipe is a task that requires precision to maintain the structural integrity of the pipe and ensure smooth exhaust flow.

Tools for Bending Exhaust Pipes

The tools you select will depend on the budget, skill level, and the complexity of the bend. Here are the main options:

- Manual Pipe Bender: Ideal for simple bends, a manual pipe bender uses a lever and die to shape the pipe. It’s cost-effective and works best for smaller projects.

- Hydraulic Pipe Bender: A more powerful option, hydraulic benders are suitable for thicker pipes and larger-scale projects. They provide precise and smooth bends.

- Exhaust Pipe Expander and Clamps: These tools help reshape ends or adjust diameters to fit joints after bending.

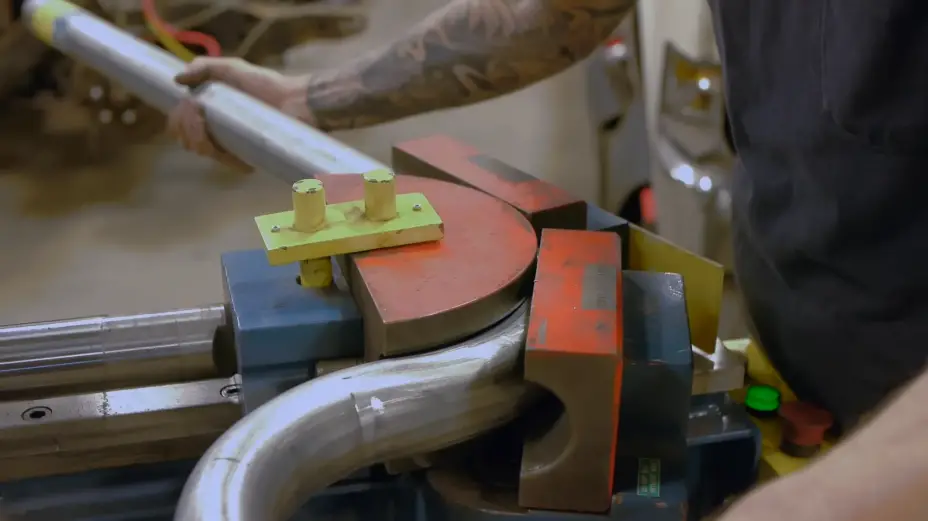

- Mandrel Bender: For professional-quality bends, a mandrel bender is unmatched. It prevents kinking and oval deformation by inserting a flexible mandrel inside the pipe.

- Heat Sources: A propane torch or similar heat source softens the metal for easier bending, reducing the risk of cracks.

- Templates and Measurement Tools: Using a bending template ensures accuracy, while protractors and markers help maintain consistent angles.

Step-by-Step Process to Bend an Exhaust Pipe

Here’s a step-by-step guide:

1. Plan and Measure

- Determine the Bend Angle: Use a protractor or an angle gauge to mark the required bend.

- Mark the Bend Area: Clearly indicate where the bend starts and ends to avoid over-bending.

2. Prepare the Pipe

- Inspect the Material: Ensure the pipe is free of rust, cracks, or impurities.

- Cut to Size: Use a pipe cutter for precise cuts if the pipe needs resizing.

- Fill the Pipe (Optional): To prevent kinking, fill the pipe with fine sand and seal both ends using duct tape or plugs.

3. Heat the Pipe (Optional)

For tougher metals like stainless steel, apply heat using a propane torch. This makes the metal pliable and reduces the likelihood of fractures. Avoid overheating, as it can weaken the pipe.

4. Use the Bender

- Setup the Tool: Secure the pipe in the bender, aligning it with the marked area.

- Start Bending: Apply consistent pressure. If using a manual or hydraulic bender, operate the lever slowly to avoid sudden movements.

- Check Progress: Regularly compare the pipe to your template or desired angle.

5. Cool Down and Inspect

Allow the pipe to cool naturally to retain its structural integrity. Inspect the bend for uniformity and adjust as needed.

6. Test Fit and Adjust

Fit the bent pipe into the exhaust system to ensure it aligns properly. Make minor adjustments if necessary.

Tips for Successful Exhaust Pipe Bending

Here are some practical tips for successfully bending exhaust pipes:

- Use the Right Die Size: Dies must match the pipe’s diameter to ensure smooth bends.

- Avoid Over-Bending: Stretching the pipe too far can cause fractures or thinning.

- Practice on Scrap Material: Before bending your actual pipe, test the process on a scrap piece to refine your technique.

- Maintain Steady Pressure: Apply pressure consistently to avoid abrupt bends or kinks.

- Work in Small Increments: For precision, bend the pipe gradually and check frequently against your template.

Common Challenges and Solutions

When bending exhaust pipes, various challenges can arise, potentially affecting the quality of the bend or the functionality of the exhaust system. Below are some common challenges and their solutions:

1. Kinking or Flattening of the Pipe

- Challenge: The pipe deforms instead of bending smoothly, restricting exhaust flow.

- Solution:

- Use a pipe bender with the correct die size for the pipe diameter.

- Pack the pipe with sand and seal the ends tightly to provide internal support.

- Use a mandrel if precision is critical, especially for tight-radius bends.

2. Cracking or Splitting

- Challenge: The pipe cracks due to excessive force or improper material handling.

- Solution:

- Heat the pipe evenly before bending to reduce stress on the metal.

- Ensure the pipe is free of rust or defects before starting.

- Avoid bending pipes at extreme angles or too quickly.

3. Misalignment of the Bend

- Challenge: The bend is not at the correct angle or location, leading to fitment issues.

- Solution:

- Carefully measure and mark the bend location using a marker and protractor.

- Perform trial fits during the bending process to confirm accuracy.

- Use bending templates for complex angles.

4. Over-Bending

- Challenge: The bend exceeds the desired angle, making it unusable.

- Solution:

- Bend the pipe incrementally and check the angle frequently.

- Use a bending guide with marked angles to track progress.

5. Weak Spots at the Bend

- Challenge: The pipe weakens at the bend, increasing the risk of failure under heat or pressure.

- Solution:

- Avoid excessive heating, which can weaken the metal.

- Use gradual bends rather than sharp angles.

- Choose high-quality materials that can withstand bending stress.

6. Uneven Bends

- Challenge: The pipe bends unevenly, causing a wavy or lopsided appearance.

- Solution:

- Ensure the pipe is centered correctly in the bender.

- Apply force evenly and slowly during bending.

- Use a high-quality bender with precise controls.

7. Surface Damage

- Challenge: Scratches, dents, or other surface damage occur during bending.

- Solution:

- Clean the pipe thoroughly before bending to remove debris that might cause scratches.

- Use padding or protective covers on the bender clamps.

8. Difficulty Bending Thick-Walled or Stainless Steel Pipes

- Challenge: Thick or stainless steel pipes require more force and are prone to cracking or incomplete bends.

- Solution:

- Use a hydraulic bender for greater force.

- Apply heat to make the pipe more pliable.

- Work slowly to avoid stressing the material.

9. Limited Access to Proper Tools

- Challenge: Without the right tools, bends may be imprecise or cause damage to the pipe.

- Solution:

- Rent or borrow a pipe bender if you don’t own one.

- For occasional projects, consider having the pipe bent at a professional exhaust shop.

10. Safety Hazards

- Challenge: Burns, cuts, or other injuries can occur during the bending process.

- Solution:

- Wear appropriate protective gear, including gloves and safety glasses.

- Keep your workspace clean and free of tripping hazards.

- Follow the equipment manufacturer’s safety guidelines.

By addressing these challenges proactively, you can achieve smooth and professional-looking bends while avoiding costly mistakes.

Safety Precautions

Bending exhaust pipes involves handling tools, heat, and potentially heavy materials, so prioritizing safety is essential. Below are key safety precautions to follow:

- Wear Protective Gear: Use gloves, safety glasses, and steel-toed boots to protect yourself from sharp edges and hot metal.

- Ventilation: Work in a well-ventilated area, especially when using heat.

- Secure the Pipe: Ensure the pipe is firmly clamped to prevent movement during bending.

- Avoid Overheating: Excessive heat can weaken the metal and create weak spots.

Related Article

How to Separate Exhaust Pipes

How To Weld Exhaust Pipe

Frequently Asked Questions

Here are some FAQs about bending exhaust pipes

1. Can I bend an exhaust pipe without special tools?

Yes, but it’s challenging. You can use improvised methods like filling the pipe with sand and bending it over a sturdy object. However, this may not produce professional results.

2. What’s the best material for exhaust pipes?

Stainless steel is ideal for durability and corrosion resistance, though aluminized steel is a more budget-friendly alternative.

3. How do I avoid kinking when bending?

To prevent kinking, use a mandrel bender or fill the pipe with sand. Slow, steady pressure also helps.

4. Can I heat the pipe with a regular blowtorch?

Yes, a propane blowtorch works well for most exhaust pipe materials. However, ensure the heat is evenly distributed.

5. How much does a professional pipe bender cost?

Prices range from $200 for manual benders to over $5,000 for high-end mandrel benders. Renting equipment is a cost-effective alternative for occasional use.

Conclusion

Bending exhaust pipes is a practical skill that enhances your ability to customize and repair exhaust systems. With the right tools, preparation, and techniques, you can achieve professional results without compromising the pipe’s structural integrity. Remember to take safety precautions and practice on scrap material to refine your skills. However you’re upgrading a car’s exhaust system or building one from scratch, proper pipe bending ensures a perfect fit and optimal performance.