To check pinion depth without a tool, apply gear marking compound and inspect the contact pattern on the gear teeth. Adjust the depth using shims until the pattern is centered. This approach relies on careful observation and patience.

Setting the correct pinion depth is critical when installing or rebuilding a differential. Proper pinion depth ensures that the pinion gear meshes correctly with the ring gear, which is vital for the longevity and performance of your vehicle’s drivetrain. While specialized tools like a pinion depth gauge are typically used to measure and set pinion depth accurately, it’s possible to check and adjust pinion depth without these tools using some basic techniques and a lot of care.

This guide will walk you through the process of checking pinion depth without a dedicated tool, providing you with practical steps and tips to ensure your differential is set up correctly.

Contents

Pinion Depth

Pinion depth refers to the distance between the centerline of the ring gear and the tip of the pinion gear’s teeth. This measurement is crucial because it determines how the gears mesh together. If the pinion depth is too shallow or too deep, it can lead to improper gear contact, resulting in noise, premature wear, or even catastrophic failure of the differential.

The ideal pinion depth varies depending on the differential and gear set, and it’s usually specified by the manufacturer. However, in the absence of specialized tools, you can use a more hands-on approach to approximate and adjust the pinion depth.

How to Check Pinion Depth Without Tool

First of all you should gather some basic tools listed below –

- Pinion Shim Kit: Shims are used to adjust the depth of the pinion gear.

- Marking Compound: Also known as gear marking compound, this is used to visually inspect the gear contact pattern.

- Dial Indicator (Optional): While not strictly necessary, a dial indicator can help measure backlash and confirm gear alignment.

- Basic Hand Tools: Wrenches, sockets, and a torque wrench for assembling and disassembling the differential.

- Feeler Gauges (Optional): Can be used to measure gaps during assembly.

- Notepad and Pen: For taking notes on the adjustments you make.

Step-by-Step Guide to Checking Pinion Depth Without a Tool

Follow the steps below to check pinion depth –

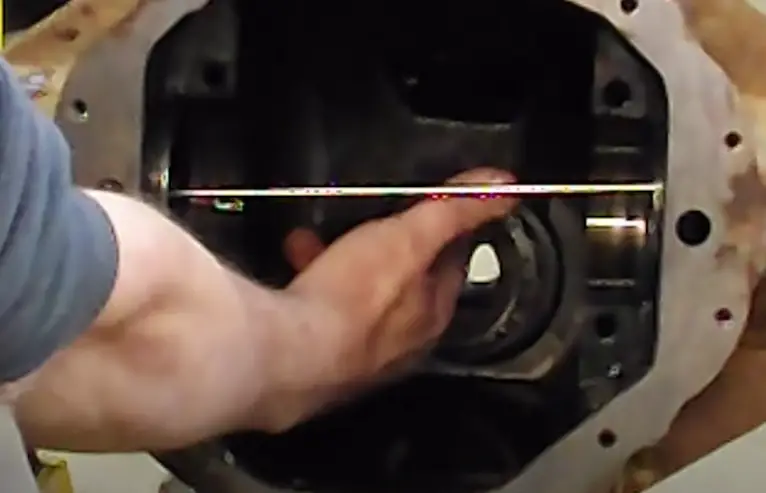

Step 1: Install the Pinion Gear

Start by installing the pinion gear into the differential housing. Depending on your differential type, you may need to install bearings, races, and seals. Ensure that the pinion bearing preload is set correctly, as this will affect your pinion depth. You can use shims to adjust the preload if necessary. Once the pinion gear is installed, the next step is to adjust the depth.

Step 2: Apply Gear Marking Compound

Apply a thin, even layer of gear marking compound to the teeth of the pinion gear. This compound will help you visualize the contact pattern between the pinion and ring gear, allowing you to make adjustments to the pinion depth.

Step 3: Install the Ring Gear

With the marking compound applied, install the ring gear onto the differential carrier. Assemble the carrier into the housing and torque the caps to the manufacturer’s specifications. Make sure the ring gear and pinion gear are meshing correctly, and that there is no excessive play or backlash.

Step 4: Rotate the Assembly

Carefully rotate the differential assembly by hand, allowing the pinion gear to turn the ring gear several times. This will create a contact pattern on the gear teeth, which you can use to assess the pinion depth. Be sure to rotate the assembly in both directions to get a full picture of the contact pattern.

Step 5: Inspect the Contact Pattern

After rotating the gears, inspect the contact pattern left by the marking compound on both the drive side (convex side) and coast side (concave side) of the gear teeth. The ideal contact pattern should be centered on the tooth, both vertically and horizontally. Here’s what to look for:

- Pattern Too Close to the Face (Outer Edge) of the Tooth: If the pattern is close to the outer edge of the tooth, the pinion depth is too shallow, and the pinion gear needs to be moved closer to the ring gear centerline.

- Pattern Too Close to the Root (Inner Edge) of the Tooth: If the pattern is near the inner edge, the pinion depth is too deep, and the pinion gear needs to be moved away from the ring gear centerline.

- Pattern Well-Centered: A centered pattern indicates that the pinion depth is correct.

Step 6: Adjust the Pinion Depth

Based on the contact pattern, adjust the pinion depth by adding or removing shims behind the pinion gear bearing. Adding shims will move the pinion closer to the ring gear (increasing depth), while removing shims will move it away (decreasing depth). This process may require several attempts to get the pattern centered.

Step 7: Recheck the Pattern

After adjusting the shims, reassemble the differential and repeat the process of applying gear marking compound, rotating the assembly, and inspecting the contact pattern. Continue making adjustments until the pattern is centered on the gear teeth.

Step 8: Final Assembly

Once you’re satisfied with the contact pattern and pinion depth, complete the final assembly of the differential. Ensure that the backlash is within the manufacturer’s specifications and that all components are torqued to the correct values. Test the rotation of the differential to make sure everything moves smoothly without binding or excessive noise.

Tips for Success

- Patience is Key: Adjusting pinion depth without specialized tools can be time-consuming. Take your time and make small, incremental adjustments to avoid overshooting the correct depth.

- Document Your Work: Keep notes on the adjustments you make, including the thickness of shims used. This will help you track your progress and avoid confusion during reassembly.

- Consult the Manual: Even without specialized tools, your vehicle’s service manual can provide valuable information on gear setup and acceptable tolerances.

- Use a Dial Indicator for Backlash: While not necessary for checking pinion depth, using a dial indicator to measure backlash can help ensure the gears are properly aligned.

FAQs

1. Can I check pinion depth without removing the differential?

No, to accurately check and adjust pinion depth, you need access to the pinion gear, which requires removing the differential cover and components.

2. How do I know if my pinion depth is too shallow or too deep?

You can determine if the pinion depth is too shallow or deep by inspecting the contact pattern on the gear teeth. A pattern too close to the face indicates shallow depth, while one near the root indicates deep depth.

3. What happens if the pinion depth is not set correctly?

Incorrect pinion depth can lead to improper gear meshing, resulting in noise, vibration, increased wear, and potential gear or bearing failure.

4. Can I use a feeler gauge to check pinion depth?

Feeler gauges are not typically used to measure pinion depth directly, but they can be helpful in checking other clearances within the differential, such as backlash.

5. How long does it take to adjust pinion depth without a tool?

The process can take several hours, especially if you need to make multiple adjustments to achieve the correct contact pattern.

Conclusion

Checking and adjusting pinion depth without specialized tools is a meticulous process that requires patience, precision, and attention to detail. By following the steps outlined in this guide and carefully inspecting the gear contact pattern, you can set the pinion depth correctly, ensuring a smooth and quiet operation of your differential. While the process may be challenging, the satisfaction of completing it successfully is well worth the effort.