To measure pinion angle, first park the vehicle on a level surface and use an angle finder or digital protractor to measure the angle of the driveshaft and the pinion yoke. Subtract the pinion angle from the driveshaft angle to determine the true pinion angle. Ensuring the correct pinion angle is crucial for smooth drivetrain operation and minimizing wear on the U-joints.

Pinion angle is a critical factor in the performance and longevity of a vehicle’s drivetrain, particularly in rear-wheel-drive vehicles. The correct pinion angle ensures that the driveshaft operates smoothly, reducing vibrations and wear on the drivetrain components. Whether you’re working on a street car, off-road vehicle, or high-performance drag racer, understanding and accurately measuring the pinion angle is essential.

Pinion Angle

Before diving into the measurement process, it’s important to understand what pinion angle is and why it matters for your vehicle.

What is Pinion Angle?

Pinion angle refers to the angle between the driveshaft and the differential pinion shaft. In a typical rear-wheel-drive vehicle, the driveshaft connects the transmission to the differential, transferring power to the rear wheels. The pinion angle is crucial because it affects how the driveshaft and U-joints operate during vehicle movement.

There are two key angles to consider:

- Driveshaft Angle: The angle of the driveshaft relative to the ground.

- Pinion Angle: The angle of the pinion gear in the differential relative to the driveshaft.

The ideal pinion angle ensures that the U-joints at both ends of the driveshaft operate within their designed range, minimizing stress and preventing vibrations. Incorrect pinion angles can lead to various issues, including:

- Excessive Vibration: If the pinion angle is too far off, it can cause the driveshaft to vibrate, especially at high speeds.

- U-Joint Wear: Improper angles increase wear on the U-joints, leading to premature failure.

- Power Loss: Incorrect pinion angle can result in inefficient power transfer, reducing overall vehicle performance.

How to Measure Pinion Angle

To measure the pinion angle accurately, you’ll need a few basic tools:

- Angle Finder or Digital Protractor: This is the most important tool, used to measure the angles of the driveshaft and pinion. A magnetic base is helpful for attaching it to metal surfaces.

- Jack and Jack Stands: To safely lift and support your vehicle, allowing access to the driveshaft and differential.

- Wrenches or Sockets: For adjusting the pinion angle if necessary.

- Pen and Paper: To record your measurements.

Steps to Measure Pinion Angle

Now that you understand the importance of pinion angle and have gathered your tools, let’s walk through the process of measuring it.

Step 1: Prepare the Vehicle

- Park on a Level Surface: Ensure your vehicle is parked on a flat, level surface. This is crucial for accurate measurements.

- Chock the Wheels: Place wheel chocks behind the front wheels to prevent the vehicle from rolling while you’re working underneath it.

- Lift the Vehicle (if needed): Use a jack to lift the rear of the vehicle and support it securely with jack stands under the axle. Ensure the suspension is loaded (under the vehicle’s weight) as it would be when driving, as this affects the pinion angle.

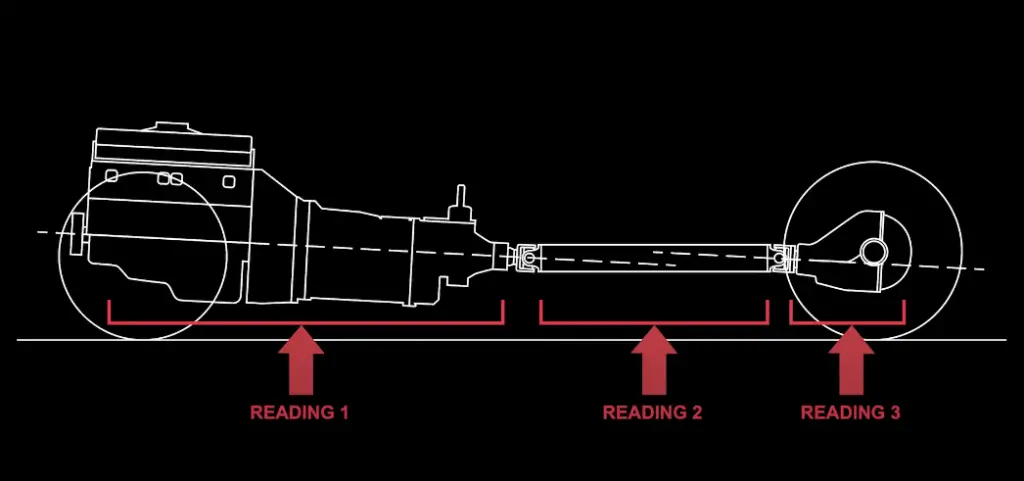

Step 2: Measure the Driveshaft Angle

- Locate the Driveshaft: Position yourself under the vehicle where you have clear access to the driveshaft.

- Attach the Angle Finder: Place the angle finder or digital protractor on the driveshaft’s flat surface. If the driveshaft is round, you can use a straight edge or a piece of metal as a base for the angle finder.

- Read the Angle: Note the angle shown on the tool. This is your driveshaft angle relative to the ground. Record this measurement.

Step 3: Measure the Pinion Angle

- Locate the Pinion Yoke: The pinion yoke is the part of the differential where the driveshaft connects.

- Attach the Angle Finder: Place the angle finder or digital protractor on the flat surface of the pinion yoke. Ensure that it is aligned properly to get an accurate reading.

- Read the Angle: Note the angle shown on the tool. This is your pinion angle relative to the ground. Record this measurement.

Step 4: Calculate the Pinion Angle

To determine the true pinion angle, you need to compare the driveshaft angle to the pinion angle.

- True Pinion Angle = Driveshaft Angle – Pinion Angle

For example:

- If your driveshaft angle is 3 degrees and your pinion angle is 1 degree, then your true pinion angle is 2 degrees.

Ideal Pinion Angle

The ideal pinion angle depends on the type of vehicle and its intended use. Generally, for most street vehicles, the pinion angle should be within 1 to 3 degrees of the driveshaft angle. Here are some guidelines:

- Street Vehicles: The pinion angle should be slightly downward (relative to the driveshaft) by 1 to 2 degrees to accommodate axle wrap or suspension movement under acceleration.

- High-Performance/Racing Vehicles: The pinion angle is often set more aggressively, sometimes up to 3 degrees downward, to counteract the greater axle movement experienced during hard acceleration.

- Off-Road Vehicles: These vehicles may require a different approach, with pinion angles adjusted to match the suspension geometry and minimize driveline stress over rough terrain.

How to Adjust Pinion Angle

If you find that your pinion angle is not within the ideal range, adjustments will be necessary. The method for adjusting the pinion angle depends on the type of suspension your vehicle has.

Leaf Spring Suspension

For vehicles with leaf spring suspensions, the pinion angle is adjusted using angled shims placed between the leaf spring and the axle. Here’s how:

- Determine the Necessary Adjustment: Calculate how many degrees of adjustment are needed based on your measurements.

- Choose the Correct Shims: Select shims that match the required angle adjustment.

- Install the Shims: Place the shims between the leaf spring and axle, ensuring they are properly aligned and secured.

- Recheck the Angle: After installing the shims, re-measure the pinion angle to ensure it is within the desired range.

Four-Link or Adjustable Control Arm Suspension

For vehicles with four-link or adjustable control arm suspensions, the pinion angle is adjusted by lengthening or shortening the control arms.

- Loosen the Control Arm Bolts: Use a wrench or socket to loosen the bolts on the control arms.

- Adjust the Control Arms: Lengthen or shorten the control arms as needed to adjust the pinion angle.

- Tighten the Bolts: Once the desired angle is achieved, tighten the control arm bolts securely.

- Recheck the Angle: Measure the pinion angle again to confirm the adjustment.

Common Mistakes to Avoid

When measuring and adjusting the pinion angle, there are some common mistakes to watch out for:

- Not Measuring on a Level Surface: Always ensure the vehicle is on a flat surface when measuring the pinion angle, as an uneven surface can lead to inaccurate readings.

- Ignoring Suspension Loading: Measure the pinion angle with the vehicle’s weight fully on the suspension. Lifting the vehicle without supporting the axle can result in an incorrect pinion angle.

- Over-adjusting: Making too large an adjustment to the pinion angle can lead to other issues, such as U-joint binding or increased vibration. Make small, incremental adjustments and recheck the angle frequently.

Conclusion

Maintaining the correct pinion angle is crucial for the smooth operation and longevity of your vehicle’s drivetrain. Whether you’re setting up a new suspension system, troubleshooting a vibration issue, or optimizing your vehicle for performance, accurately measuring and adjusting the pinion angle is essential.