To remove a crankshaft pulley without a special tool, use a breaker bar or long-handled wrench to loosen the pulley bolt by securing it against a solid surface and briefly turning the engine with the starter motor. You can then gently pry the pulley off using a flat-head screwdriver or pry bar. This method requires caution to avoid damaging the pulley or surrounding components.

Removing a crankshaft pulley is usually a task that requires a specialized pulley removal tool, but there are situations where you may need to remove the pulley without access to this tool. The crankshaft pulley, also known as the harmonic balancer, is a vital component that drives various accessories such as the alternator, power steering pump, and air conditioning compressor.

While it’s generally advisable to use the correct tools, you can remove the crankshaft pulley using alternative methods if you find yourself in a pinch.

Contents

Reasons for Removing a Crankshaft Pulley

There are several reasons you might need to remove a crankshaft pulley:

- Timing Belt Replacement: Many vehicles require the removal of the crankshaft pulley to access the timing belt or chain.

- Pulley Replacement: If the pulley is worn, damaged, or has a faulty harmonic balancer, it needs to be replaced.

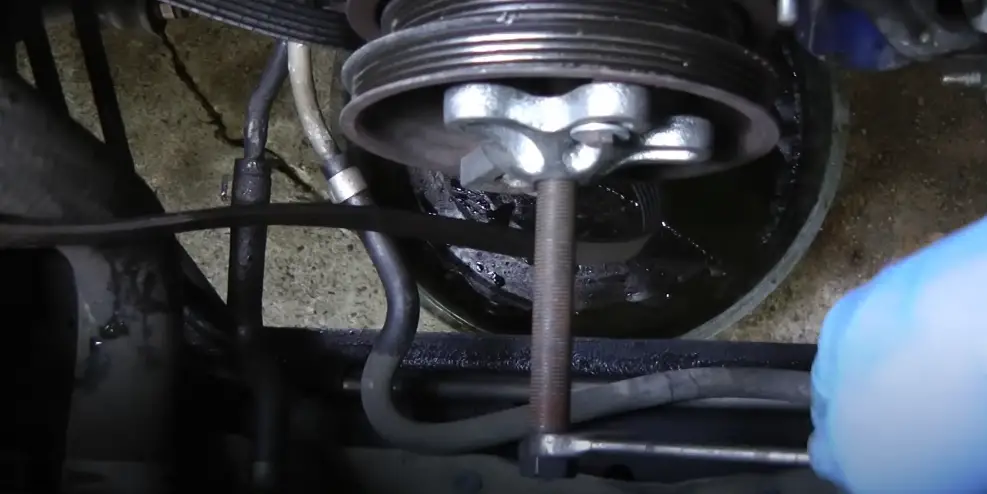

- Seal Replacement: Leaks around the crankshaft seal might require pulley removal to replace the seal.

- Engine Repairs: Major engine repairs often require removal of the crankshaft pulley to access other components.

How to Remove Crankshaft Pulley Without Tool

Disclaimer: Removing a crankshaft pulley without the proper tools can be risky. Be sure to take safety precautions, such as wearing protective gear, ensuring the vehicle is securely lifted, and disconnecting the battery. Proceed with caution, and if unsure, consult a professional mechanic.

Removing the Crankshaft Pulley Without Tool – Step by Step

Removing a crankshaft pulley without the specialized tool can be challenging, but it’s possible with some improvisation. Here’s a step-by-step guide to do it safely:

Tools and Materials Needed:

- A sturdy breaker bar or long-handled wrench

- A suitable socket (usually 17mm, 19mm, or 22mm) that fits the crankshaft bolt

- Penetrating oil (e.g., WD-40)

- Pry bar or long flat-head screwdriver

- Thick gloves and safety glasses

- Jack stands and wheel chocks

Step 1: Prepare the Vehicle

- Park the Vehicle on a Level Surface: Ensure the car is on a flat, stable surface and engage the parking brake.

- Disconnect the Battery: For safety, disconnect the negative terminal of the battery to avoid accidental electrical discharge.

- Lift the Front of the Vehicle: Use a jack to lift the front of the vehicle and secure it on jack stands. Place wheel chocks behind the rear wheels to prevent movement.

Step 2: Access the Crankshaft Pulley

- Remove the Serpentine Belt: Locate the serpentine belt that runs over the crankshaft pulley. Use a wrench or breaker bar to rotate the tensioner pulley and relieve tension on the belt, then slide the belt off the pulleys.

- Locate the Crankshaft Pulley Bolt: Find the bolt at the center of the crankshaft pulley. This bolt is typically very tight, as it holds the pulley securely to the crankshaft.

Step 3: Loosen the Crankshaft Pulley Bolt

- Apply Penetrating Oil: Spray penetrating oil on the crankshaft pulley bolt and allow it to sit for a few minutes. This will help break any rust or corrosion, making it easier to remove.

- Use a Breaker Bar or Long Wrench: Attach the appropriate socket to the breaker bar or long-handled wrench and place it on the crankshaft pulley bolt.

- Position the Breaker Bar Against a Solid Surface: Rotate the breaker bar until it rests against a solid part of the vehicle’s frame or suspension. This will help hold the bar in place when you turn the engine.

- Turn the Engine Using the Starter Motor: With the breaker bar in place, have a helper briefly “bump” the ignition key to turn the engine over for a split second. The force generated by the engine’s rotation should break the bolt loose. Caution: Do not start the engine; just turn the key enough to nudge the crankshaft. Make sure your hands are clear of the moving parts.

Step 4: Remove the Crankshaft Pulley

- Manually Remove the Bolt: Once the bolt is loose, you can remove it by hand. Be prepared for the pulley to be heavy or stuck due to grime or rust.

- Pry the Pulley Off: Use a pry bar or flat-head screwdriver to gently work around the edges of the pulley. Apply even pressure on all sides to gradually loosen and remove the pulley from the crankshaft.

Risks and Safety Considerations of Removing Crankshaft Pulley

- Risk of Injury: Using the starter motor to break the crankshaft bolt loose is inherently risky. Ensure you have clear communication with your helper and take extreme care to avoid injury.

- Potential Damage to Components: Without the correct tools, there is a risk of damaging the crankshaft, pulley, or other engine components.

- Engine Misalignment: If not done properly, removing the crankshaft pulley can result in misalignment of the engine’s timing marks, leading to poor engine performance or internal damage.

Alternative Methods of Removing the Crankshaft Pulley

If you do not have access to specialized tools, here are some alternative methods that may help:

- Impact Wrench: If available, an impact wrench can be used to remove the crankshaft pulley bolt more easily than a manual wrench.

- Rope or Strap Method: Some mechanics use a thick rope or strap to wrap around the pulley and secure it to a solid part of the engine bay, creating a makeshift pulley holder. However, this method requires caution and is not always effective.

- Heat Application: Carefully applying heat to the bolt with a heat gun can help break any rust or corrosion. Be mindful of flammable components in the engine bay.

Related Article

Can Crankshaft Pulley Smoke?

What Does a Bad Crankshaft Pulley Sound Like?

Frequently Asked Questions

Here are some FAQs about the removing a crankshaft pulley without a tool –

1. Is it safe to remove the crankshaft pulley without a special tool?

While it is possible to remove a crankshaft pulley without a special tool, it is not always safe or advisable. Improper removal can cause injury or damage to engine components, so use caution and consider consulting a professional mechanic.

2. Can I use heat to loosen the crankshaft pulley bolt?

Yes, applying controlled heat to the bolt can help break rust or corrosion. However, be careful to avoid damaging surrounding components or causing a fire hazard.

3. What should I do if the crankshaft pulley is stuck?

If the pulley is stuck, apply penetrating oil around the pulley hub and allow it to soak for several minutes. Then, use a pry bar or flat-head screwdriver to gently work around the edges, applying even pressure.

4. How tight is the crankshaft pulley bolt supposed to be?

The crankshaft pulley bolt is typically torqued very tightly, often to 100-150 ft-lbs, depending on the vehicle. Consult your vehicle’s service manual for the specific torque specification.

5. Can removing the crankshaft pulley affect engine timing?

Yes, if the crankshaft pulley removal is not done carefully, it can affect engine timing, especially on vehicles with timing belts or chains. Always check and realign the timing marks before reassembly.

Conclusion

Removing a crankshaft pulley without a special tool can be challenging and risky, but it is possible with the right approach and safety precautions. Understanding the causes and symptoms that may necessitate pulley removal, along with following a careful step-by-step guide, can help you accomplish the task successfully.