To tell if a crankshaft is forged or cast, you can check the parting line, surface texture, and weight. Forged crankshafts have a narrow, sharp parting line, smoother surface, and are generally heavier due to their denser material. In contrast, cast crankshafts have a wider, rounded parting line, a rougher texture, and are lighter. Additionally, a sound test can help, with forged crankshafts producing a clearer ringing sound when tapped.

The crankshaft is one of the most critical components of an internal combustion engine. It converts the linear motion of the pistons into rotational motion, driving the vehicle’s wheels. Crankshafts are typically made from either forged or cast metal, and the differences between these manufacturing processes can significantly impact the crankshaft’s performance, durability, and suitability for specific applications.

Contents

Forged and Cast Crankshafts

Before diving into the identification methods, it’s important to understand what forged and cast crankshafts are and how they differ.

1. Forged Crankshafts

Manufacturing Process: Forged crankshafts are made by heating a billet of steel to a high temperature and then shaping it under extreme pressure using a forging die. This process aligns the metal’s grain structure, making it denser and stronger.

Strength and Durability: Due to the forging process, forged crankshafts are generally stronger and more durable than their cast counterparts. They are often used in high-performance and heavy-duty applications where the engine is subjected to high stress and loads.

Cost: Forged crankshafts are more expensive to produce, which is reflected in their higher price. However, their superior strength often justifies the cost, especially in performance engines.

2. Cast Crankshafts

Manufacturing Process: Cast crankshafts are made by pouring molten metal into a mold (or cast), where it solidifies into the desired shape. This process is less labor-intensive and allows for more complex shapes but results in a less dense grain structure compared to forging.

Strength and Durability: While cast crankshafts are generally sufficient for most standard engines, they are not as strong as forged crankshafts. They are more prone to cracking under high stress, making them less suitable for high-performance applications.

Cost: Cast crankshafts are less expensive to produce, making them a cost-effective option for standard, everyday engines.

How to Tell if a Crankshaft is Forged or Cast?

There are several methods to determine whether a crankshaft is forged or cast, ranging from visual inspection to more technical methods.

1. Visual Inspection

One of the simplest ways to tell if a crankshaft is forged or cast is through visual inspection. By examining the crankshaft’s surface and features, you can often make an educated guess about its manufacturing process.

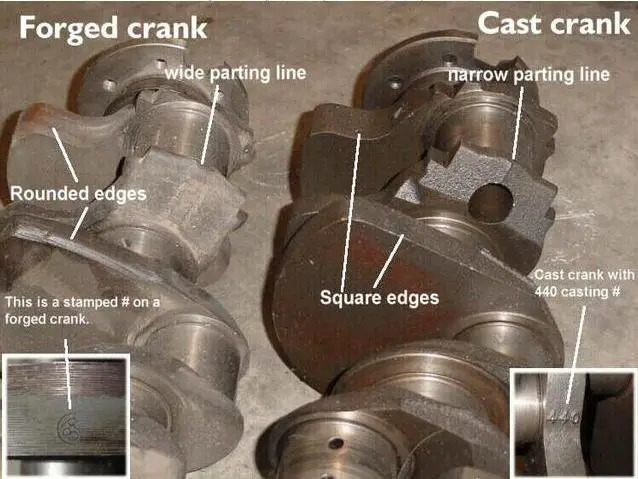

- Parting Line: The parting line is where the two halves of the mold meet in a cast crankshaft or where the forging die splits in a forged crankshaft.

- Forged Crankshafts: The parting line on a forged crankshaft is usually narrow and sharp because of the high-pressure forging process. It often looks like a thin, raised line.

- Cast Crankshafts: The parting line on a cast crankshaft is wider and more rounded. This is because the mold’s edges aren’t as tightly pressed together as in forging, resulting in a wider line.

- Surface Texture: The surface texture can also provide clues about the crankshaft’s origin.

- Forged Crankshafts: Typically, forged crankshafts have a smoother surface with fine lines or striations running along the axis of the crankshaft. These lines are the result of the forging process.

- Cast Crankshafts: Cast crankshafts often have a rougher, more porous surface. The casting process can leave small imperfections or a slightly grainy texture on the surface.

- Weight: Generally, forged crankshafts are heavier than cast crankshafts because of their denser material. While this difference might not be immediately obvious without a comparison, it can be noticeable when holding the crankshaft.

2. Sound Test

Another method to differentiate between forged and cast crankshafts is the sound test, which involves tapping the crankshaft with a metallic object like a wrench or hammer.

- Forged Crankshafts: When tapped, a forged crankshaft produces a clear, ringing sound due to its dense material.

- Cast Crankshafts: A cast crankshaft, on the other hand, typically produces a duller, more muted sound. This is due to its less dense structure, which dampens vibrations.

3. Magnetic Particle Inspection (MPI)

Magnetic Particle Inspection (MPI) is a more technical method used to examine the internal structure of the crankshaft. This method involves magnetizing the crankshaft and then applying ferromagnetic particles to its surface. Any imperfections or differences in the material’s density will disrupt the magnetic field, revealing lines or patterns that indicate the crankshaft’s composition.

- Forged Crankshafts: In an MPI test, forged crankshafts show a more uniform pattern with fewer disruptions because of their consistent grain structure.

- Cast Crankshafts: Cast crankshafts often exhibit more irregular patterns, especially around the grain boundaries and parting lines, due to their less uniform structure.

4. X-Ray or Ultrasound Testing

For those with access to advanced diagnostic equipment, X-ray or ultrasound testing can provide definitive answers about whether a crankshaft is forged or cast.

- Forged Crankshafts: X-ray or ultrasound imaging of a forged crankshaft will show a tightly packed, uniform grain structure with fewer internal voids or defects.

- Cast Crankshafts: These tests will reveal a more porous, uneven structure in a cast crankshaft, with potential internal defects such as small cavities or inclusions.

5. Manufacturer Markings and Documentation

If the crankshaft is still in its original state and has not been modified, you can also check for manufacturer markings or refer to the documentation. Many manufacturers will stamp or etch identifying marks on the crankshaft, which can indicate whether it is forged or cast.

- Forged Crankshafts: Often have specific markings or codes that can be cross-referenced with manufacturer data to confirm the forging process.

- Cast Crankshafts: Similarly, cast crankshafts may have identifying marks that correlate with casting data from the manufacturer.

Source: dropforging.net

When to Choose Forged Over Cast Crankshafts

Understanding the differences between forged and cast crankshafts is not just about identification; it’s also about choosing the right crankshaft for your specific application.

- High-Performance Engines: If you are building or modifying an engine for high-performance use, such as racing or heavy-duty towing, a forged crankshaft is typically the better choice due to its superior strength and durability.

- Standard or Mild Performance: For everyday driving or mildly modified engines, a cast crankshaft is often sufficient and more cost-effective.

- Engine Longevity and Reliability: If long-term reliability and the ability to withstand high loads are priorities, investing in a forged crankshaft can provide peace of mind and reduce the risk of failure under stress.

Related Article

Are Fully Counterweighted Crankshaft Durable?

Crankshaft Journal Welding

How to Polish Crankshaft Journals

Are Crankshaft Bolts Reverse Thread?

Frequently Asked Questions

Here are some FAQs about the forged and cast crankshaft –

1. How can I tell if my crankshaft is forged or cast?

You can identify a forged or cast crankshaft through visual inspection, sound testing, and technical methods like Magnetic Particle Inspection (MPI) or X-ray testing. Key indicators include the parting line, surface texture, weight, and the sound it produces when tapped.

2. Are forged crankshafts always better than cast crankshafts?

Forged crankshafts are generally stronger and more durable, making them ideal for high-performance and heavy-duty applications. However, cast crankshafts are more than sufficient for standard engines and are more cost-effective for everyday use.

3. Can I use a cast crankshaft in a performance engine?

While a cast crankshaft can be used in a performance engine, it may not withstand the high stress and loads as well as a forged crankshaft. For serious performance applications, a forged crankshaft is recommended.

4. What are the risks of using a cast crankshaft in a high-stress engine?

Using a cast crankshaft in a high-stress engine can lead to issues like cracking, fatigue, and premature failure. This is because cast crankshafts have a less dense grain structure, making them more susceptible to damage under extreme conditions.

5. Is there a price difference between forged and cast crankshafts?

Yes, forged crankshafts are generally more expensive due to the more labor-intensive manufacturing process and their superior strength. Cast crankshafts are less expensive to produce and purchase, making them a budget-friendly option for standard applications.

Conclusion

Distinguishing between a forged and cast crankshaft is a valuable skill for anyone involved in automotive repair, engine building, or performance tuning. By understanding the key differences in manufacturing processes, visual characteristics, and material properties, you can make informed decisions about the crankshaft’s suitability for your specific needs.

Whether you’re evaluating a crankshaft for a high-performance build or simply ensuring the reliability of a standard engine, the ability to identify forged and cast crankshafts can have a significant impact on your engine’s performance and longevity.