To turn a crankshaft with a breaker bar, first, locate the crankshaft pulley and attach a suitable socket to the pulley bolt. Then, use the breaker bar to apply steady force, typically turning the crankshaft clockwise. This method allows for precise control during tasks like timing adjustments or engine diagnostics.

Turning the crankshaft by hand is an essential procedure for various automotive tasks, such as timing adjustments, valve clearance checks, and engine diagnostics. Using a breaker bar to manually rotate the crankshaft is a method preferred by many mechanics due to its simplicity and effectiveness.

Contents

How to Turn Crankshaft with Breaker Bar

The crankshaft is a vital component in an internal combustion engine, converting the linear motion of the pistons into rotational motion, which ultimately powers the vehicle’s wheels. Proper alignment and timing of the crankshaft are essential for the engine’s smooth operation.

Tools and Equipment Needed

To turn the crankshaft using a breaker bar, you will need the following tools:

- Breaker Bar: A long-handled tool that provides the necessary leverage to rotate the crankshaft. The length of the handle increases the torque, making it easier to turn the crankshaft.

- Socket: A deep socket that fits the crankshaft pulley bolt (usually found in sizes like 17mm, 19mm, or 21mm, depending on the vehicle). The socket must be compatible with the breaker bar.

- Gloves and Safety Gear: Protect your hands with gloves and ensure you are working in a safe environment with proper lighting.

- Penetrating Oil (Optional): If the crankshaft bolt is particularly stubborn or has been sitting for a long time, applying penetrating oil can make it easier to turn.

Turning the Crankshaft with a Breaker Bar -Step-by-Step

Follow the step by step guide below to do the job successfully –

1. Preparation

Before you begin, ensure the vehicle is in a safe and stable position. If the car is on the ground, ensure the parking brake is engaged. If the vehicle is lifted, use sturdy jack stands to support it. This is important because you will be applying significant force to turn the crankshaft, and stability is crucial for safety.

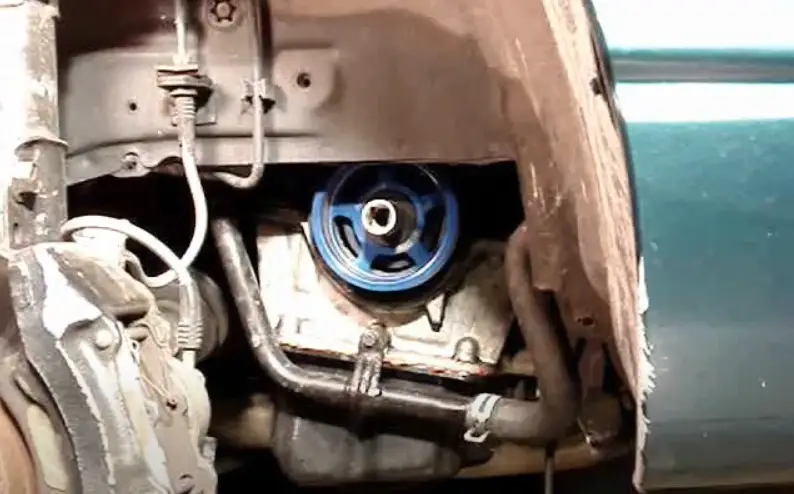

2. Locate the Crankshaft Pulley

The crankshaft pulley is usually located at the front of the engine, near the bottom. It is connected to the crankshaft and typically drives the accessory belts. Depending on your vehicle, you may need to remove certain components like the serpentine belt or the engine cover to access the crankshaft pulley.

3. Select the Appropriate Socket

Identify the size of the crankshaft pulley bolt and select the appropriate socket. Attach the socket to the breaker bar. The socket should fit snugly onto the bolt to prevent rounding or slipping.

4. Attach the Breaker Bar

Place the socket attached to the breaker bar onto the crankshaft pulley bolt. Ensure that the breaker bar is positioned in a way that allows you to apply force comfortably. Depending on the space available, you may need to reposition the bar for optimal leverage.

5. Rotate the Crankshaft

With the breaker bar securely attached, apply steady, controlled force to turn the crankshaft. The direction in which you turn the crankshaft depends on the task at hand:

- Clockwise Rotation: In most cases, you’ll turn the crankshaft clockwise (as viewed from the front of the engine). This is the direction the engine naturally rotates during operation.

- Counterclockwise Rotation: Some specific tasks, like certain timing belt installations, may require you to rotate the crankshaft counterclockwise. Always refer to your vehicle’s service manual for specific instructions.

If the crankshaft is difficult to turn, avoid using excessive force, as this could damage the bolt or crankshaft. Instead, check for any obstructions, or consider applying penetrating oil to loosen the bolt.

6. Observe the Engine Components

As you turn the crankshaft, observe the movement of the engine components. This is particularly important if you are checking timing marks, valve clearance, or piston position. Ensure that all components are moving smoothly and there are no unusual noises or resistance.

7. Final Checks and Reassembly

Once you have completed the necessary rotations and observations, carefully remove the breaker bar and socket. Reassemble any components you may have removed, such as the serpentine belt or engine cover. Double-check that everything is securely in place before starting the engine.

Precautions and Tips

- Avoid Excessive Force: Never apply excessive force when turning the crankshaft, as this can cause damage. If the crankshaft doesn’t turn easily, investigate the cause rather than forcing it.

- Check the Timing Marks: If you are rotating the crankshaft to check or adjust timing, make sure the timing marks on the crankshaft and camshaft align correctly. Incorrect timing can lead to poor engine performance or damage.

- Work Slowly and Deliberately: Turning the crankshaft by hand is a delicate process. Take your time and rotate the crankshaft slowly to avoid any mishaps.

- Inspect the Belt Tensioner: If your vehicle uses a serpentine belt, check the tensioner while turning the crankshaft. A worn tensioner can cause the belt to slip or come off during operation.

- Consult the Service Manual: Always refer to your vehicle’s service manual for specific instructions and torque specifications related to turning the crankshaft.

Related Article

Crankshaft Bolt Torque Specs

When to Replace Crankshaft Seal

Crankshaft Seal Leak

Crankshaft Not Turning by Hand

Frequently Asked Questions

Here are some FAQs about turning the crankshaft using a breaker bar –

1. Why would I need to turn the crankshaft by hand?

Turning the crankshaft by hand is necessary for tasks like checking engine timing, adjusting valves, diagnosing engine problems, and performing certain repairs. It allows for precise control over the engine’s components without starting the engine.

2. Can I turn the crankshaft counterclockwise?

In most cases, the crankshaft should be turned clockwise, as this is the engine’s natural direction of rotation. However, certain tasks may require counterclockwise rotation.

3. What size breaker bar should I use?

A breaker bar typically ranges from 18 to 24 inches in length, providing the necessary leverage to turn the crankshaft. The specific size you need depends on the engine and the space available to work.

4. What should I do if the crankshaft won’t turn?

If the crankshaft won’t turn, avoid applying excessive force. Check for obstructions, ensure the transmission is in neutral (or park), and consider applying penetrating oil to the crankshaft bolt. If the problem persists, consult a professional mechanic.

5. Is it safe to turn the crankshaft with the spark plugs installed?

Yes, it is generally safe to turn the crankshaft with the spark plugs installed. However, removing the spark plugs can make the crankshaft easier to turn by relieving compression pressure in the cylinders, especially if you’re rotating the crankshaft for extended periods.

Conclusion

Turning the crankshaft with a breaker bar is a fundamental skill for any DIY mechanic or professional. It allows you to perform a variety of essential tasks, from timing belt replacements to engine diagnostics. By following the steps outlined in this guide, you can safely and effectively turn the crankshaft, ensuring the engine remains in top condition. Remember to work carefully, avoid excessive force, and always follow your vehicle’s service manual for specific instructions.