Inspect and clean the rotor or drum, then securely mount it on the brake lathe. Align properly, adjust the cutting depth, and machine the surface smoothly. Clean the component, reinstall it, and test the brakes.

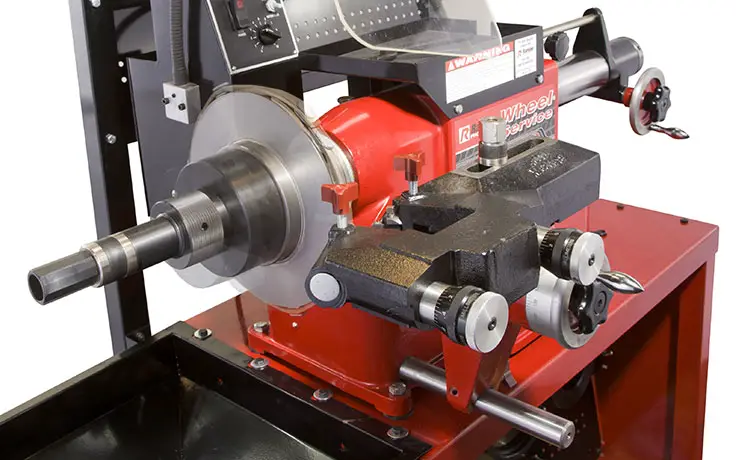

Brake lathes are essential tools in automotive repair, specifically for resurfacing brake rotors and drums to ensure smooth and effective braking. Proper use of a brake lathe not only extends the life of braking components but also enhances vehicle safety.

This guide covers everything you need to know about using a brake lathe, including its types, preparation steps, operational procedures, safety precautions, and maintenance tips.

Contents

What is Brake Lathes?

A brake lathe is a machine used to resurface brake rotors and drums, ensuring smooth braking and extending the life of brake components.

Brake lathes come in two main types:

- On-Car Brake Lathe: These machines work directly on the vehicle, ensuring that the rotor is machined in alignment with the hub, which reduces the risk of run-out.

- Off-Car Brake Lathe: These machines require the removal of the rotor or drum from the vehicle. They are commonly used in shops due to their versatility and precision.

How to Use a Brake Lathe

Before operating a brake lathe, gather all necessary tools and safety gear to ensure an efficient and safe process.

- Brake lathe (on-car or off-car)

- Safety glasses and gloves

- Dial indicator gauge

- Calipers or micrometers

- Torque wrench

- Cleaning brush or brake cleaner

- Wheel chocks and jack stands

Step-by-Step Guide to Using a Brake Lathe

Here’s a step-by-step guide to using a brake lathe:

1. Preparation

- Inspect the Rotor/Drum: Check for deep grooves, cracks, or excessive wear. If the component is below minimum thickness, replacement is necessary.

- Secure the Vehicle: Use wheel chocks and jack stands to stabilize the vehicle. For off-car lathes, remove the rotor or drum.

- Clean the Surface: Use a brake cleaner or wire brush to remove rust and debris.

2. Setup

- Mount the Rotor/Drum: For off-car lathes, use appropriate adapters to mount the rotor or drum securely. On-car lathes require alignment with the hub.

- Check Alignment: Use a dial indicator to measure run-out and ensure proper alignment.

- Select Cutting Depth: Adjust the cutting tool to remove the minimum amount of material necessary.

3. Machining Process

- Start the Lathe: Turn on the machine and begin the cutting process at a slow feed rate.

- Monitor Progress: Observe the machining to ensure a smooth, continuous cut. Adjust feed rates if needed.

- Final Pass: After the initial cut, perform a light finish pass for a smoother surface.

4. Post-Machining Inspection

- Measure Thickness: Use calipers to verify the rotor or drum is within safe thickness limits.

- Check for Smoothness: Ensure the surface is smooth and free from grooves or imperfections.

- Clean the Component: Remove metal shavings and dust with a cleaner.

5. Reinstallation and Testing

- Reinstall the Rotor/Drum: Mount the component back on the vehicle, torque bolts to manufacturer specifications.

- Test the Brakes: Perform a test drive to check for vibrations or noise.

Safety Precautions

Here are key safety precautions when using a brake lathe:

- Wear Personal Protective Equipment (PPE): Always wear safety goggles, ear protection, and gloves to protect yourself from flying debris, loud noise, and sharp edges.

- Inspect the Lathe: Before use, ensure the lathe is in good working condition and all safety guards are in place.

- Secure the Workpiece: Ensure the brake rotor or drum is properly mounted and tightly secured to avoid it becoming loose during operation.

- Avoid Loose Clothing and Jewelry: Keep loose clothing, jewelry, and hair away from the lathe to prevent them from getting caught in the machine.

- Monitor for Overheating: Keep an eye on the brake rotor/drum for excessive heat buildup during the cutting process, which could affect performance or cause burns.

- Know Emergency Stops: Familiarize yourself with the emergency stop mechanism on the lathe to quickly shut down the machine in case of a problem.

- Keep the Work Area Clean: A clutter-free workspace reduces the risk of accidents. Clean up any debris or oil spills immediately.

- Avoid Distractions: Stay focused on the task at hand and avoid any distractions while operating the brake lathe.

- Proper Ventilation: If working with any chemicals or materials that emit fumes, ensure proper ventilation in the workspace.

Maintenance Tips for Brake Lathes

Here are some essential maintenance tips for brake lathes:

- Clean Regularly: After each use, clean the lathe to remove debris, brake dust, and oil. This prevents buildup that can affect the machine’s performance.

- Lubricate Moving Parts: Regularly lubricate the lathe’s moving components, including spindles, gears, and bearings, to ensure smooth operation and prevent wear.

- Inspect for Wear: Check cutting tools and other components for signs of wear or damage. Replace or sharpen them as necessary to maintain precision.

- Check Alignment: Ensure the lathe’s spindle and other components are properly aligned. Misalignment can lead to inaccurate cuts and uneven surface finishes.

- Tighten Loose Parts: Periodically check and tighten all bolts, screws, and other fasteners to prevent vibration and ensure safe operation.

- Calibrate the Lathe: Regularly calibrate the lathe to ensure it maintains accurate settings, especially after any maintenance or part replacement.

- Monitor for Overheating: Keep an eye on the machine’s temperature. Overheating can damage components, so ensure proper cooling and ventilation.

- Replace Worn Belts: Inspect the drive belts and replace any that show signs of wear, cracking, or damage to avoid machine failure.

- Maintain Electrical Components: Inspect and clean electrical connections to prevent issues like power loss or electrical short circuits.

- Follow Manufacturer’s Guidelines: Always refer to the manufacturer’s manual for specific maintenance schedules and instructions to extend the life of your brake lathe.

Frequently Asked Questions

Here are some FAQs about how to use a brake lathe –

1. Can all rotors and drums be resurfaced?

Not all rotors and drums can be resurfaced. If they are below the minimum thickness or have severe damage, they must be replaced.

2. How often should brake rotors be resurfaced?

Resurfacing is typically done during brake pad replacement or when there are symptoms like vibrations or noise. It depends on the vehicle’s usage and condition.

3. What causes brake rotor warping?

Warping can result from excessive heat, improper installation, or uneven torque on lug nuts. Proper maintenance can prevent this.

4. Is it better to replace or resurface rotors?

If rotors are within thickness specifications and have minor wear, resurfacing is cost-effective. Severely worn or damaged rotors should be replaced.

5. Can I use a brake lathe at home?

While possible, using a brake lathe at home requires mechanical skills, proper equipment, and safety precautions. It’s often best left to professionals.

Conclusion

Using a brake lathe effectively requires understanding the machine, proper setup, and strict adherence to safety practices. Whether you’re resurfacing rotors or drums, following these steps ensures optimal brake performance and vehicle safety.