Is exhaust pipe measured ID or OD? Exhaust pipe is typically measured by its outside diameter (OD) in most automotive applications. This ensures compatibility with exhaust components like mufflers, clamps, and tips that are designed to slip over the pipe.

When working on the vehicle’s exhaust system, one crucial detail can easily be overlooked: is the exhaust pipe measured ID or OD? This question, while seemingly minor, can have significant implications on the fit, performance, and safety of your exhaust setup. If you’re upgrading to a performance system, replacing rusted components, or fabricating a custom build, knowing how to measure your exhaust pipe correctly is essential.

This comprehensive guide breaks down the difference between ID (Inside Diameter) and OD (Outside Diameter), explains which one is used for exhaust piping, and provides practical tips for measurement, installation, and compatibility.

Contents

- 1 What is Meant by ID and OD?

- 2 Why the Distinction Matters in Automotive Exhaust Systems

- 3 Is Exhaust Pipe Measured ID or OD?

- 4 Industry Standards: ID vs OD

- 5 How to Measure the Exhaust Pipe Accurately

- 6 The Role of Wall Thickness in Pipe Measurement

- 7 Why OD is Used for Exhaust Pipe Sizing

- 8 ID Measurements and Muffler/Resonator Fitment

- 9 Pipe Sizing in Aftermarket vs OEM Applications

- 10 Tips for Buying and Fitting Exhaust Components

- 11 Common Mistakes When Measuring Pipes

- 12 Frequently Asked Questions

- 13 Conclusion

What is Meant by ID and OD?

Before answering whether the exhaust pipe is measured ID or OD, it’s important to define these two terms clearly:

- Inside Diameter (ID): This is the measurement of the hollow space within the pipe, excluding the pipe wall thickness.

- Outside Diameter (OD): This measures the total outer width of the pipe, including the wall thickness.

The difference can be significant depending on the gauge (thickness) of the material used in the pipe. For instance, a pipe with a 2.5″ OD and 0.065″ wall thickness will have an ID of roughly 2.37″.

Why the Distinction Matters in Automotive Exhaust Systems

In the context of an exhaust system, accurate pipe sizing is critical. Poorly sized components can result in:

- Leaky connections

- Reduced engine performance

- Excessive noise or vibrations

- Premature wear or failure of parts

The main question — is exhaust pipe measured ID or OD — determines how your parts will fit together and how efficiently exhaust gases flow through the system.

Is Exhaust Pipe Measured ID or OD?

In almost all automotive applications, exhaust pipe is measured by OD (Outside Diameter).

This standard is especially consistent in aftermarket exhaust systems, mandrel bends, header collectors, and straight tubing. If you purchase a 2.5” exhaust pipe, it means the OD is 2.5 inches. The inside diameter will be slightly smaller due to the pipe’s wall thickness.

Industry Standards: ID vs OD

When talking about industry standards regarding ID (Inside Diameter) vs OD (Outside Diameter), it really depends on the type of product or industry—pipes, tubing, fasteners, electrical conduit, bearings, etc.—as different standards and practices apply. Here’s a breakdown across major areas:

Automotive Industry

In the automotive world, OD measurement is the standard because it simplifies the connection between pipes and components like mufflers, tips, and catalytic converters. This standard ensures parts from different manufacturers can work together.

For example:

- A 2.5″ OD exhaust pipe will fit into a 2.5″ ID muffler inlet.

- Exhaust clamps and couplers are also designed with OD sizing in mind.

Plumbing Industry

In contrast, the plumbing industry often uses ID as the standard, as the flow capacity is typically more important than the pipe’s outer dimensions.

This difference is one of the reasons why people often get confused when shopping for exhaust components.

How to Measure the Exhaust Pipe Accurately

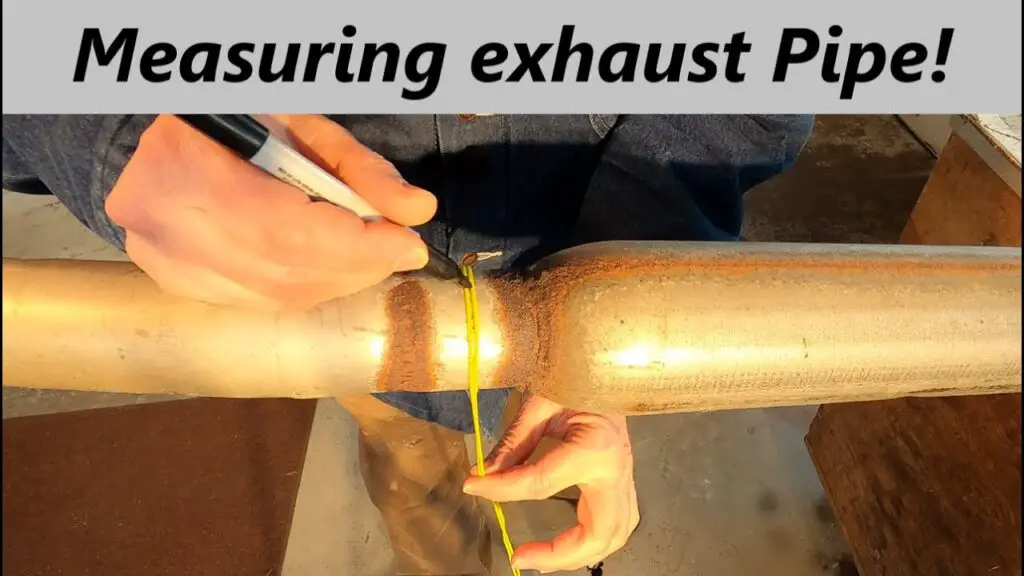

You can use a few different tools to measure an exhaust pipe, but the goal is always to determine the OD unless otherwise specified. Here’s how:

Tools Needed:

- Tape Measure

- Digital Caliper

- Tailor’s Tape (for curved or installed pipes)

Method:

- Locate the pipe’s open end (or cut it if needed).

- Use a tape measure or caliper to measure from the outside of one wall to the outside of the opposite wall.

- If the pipe is curved or inaccessible:

- Wrap a tailor’s tape around the pipe to get the circumference.

- Divide the circumference by π (3.1416) to get the diameter.

Pro Tip: For the most accurate results, use a digital caliper, especially if you’re dealing with mandrel bends or precise slip-fit connections.

The Role of Wall Thickness in Pipe Measurement

The exhaust pipe wall thickness is important because it affects the ID.

For example:

- A 2.5″ OD pipe with a 0.065″ wall thickness will have an ID of approximately 2.37″.

- This matters when you’re using components that fit inside the pipe (like insert-style O2 sensors or reducers).

Most automotive exhaust pipes use either 16-gauge (0.065″) or 18-gauge (0.049″) tubing.

Why OD is Used for Exhaust Pipe Sizing

Using OD as the measurement standard provides consistency and simplicity:

- Consistent Part Matching: Mufflers, resonators, and exhaust tips are designed based on OD.

- Slip Fit: A 2.5” OD pipe fits into a 2.5” ID muffler.

- Clamp Compatibility: Exhaust clamps and flanges are sized for OD.

This industry-wide practice helps avoid mismatches and ensures tight, leak-free seals in the system.

ID Measurements and Muffler/Resonator Fitment

While pipes are measured by OD, many exhaust components like mufflers, resonators, and tips are measured by their ID — because they need to fit over the exhaust pipe.

This dual system (pipe = OD, component = ID) ensures a secure slip-fit.

Pipe Sizing in Aftermarket vs OEM Applications

The difference between pipe sizing in aftermarket vs OEM (Original Equipment Manufacturer) applications can have a major impact—especially in automotive, HVAC, and industrial systems. Here’s a breakdown of how they differ and what to watch out for:

- OEM (Original Equipment Manufacturer): Uses precise OD measurements but can sometimes include custom flared or swaged ends.

- Aftermarket: Follows a strict OD measurement convention to ensure universal fitment and compatibility with various brands.

Always verify the spec sheet or product listing to avoid confusion.

Tips for Buying and Fitting Exhaust Components

Here’s are tips for buying and fitting exhaust components, especially when mixing OEM and aftermarket parts. Exhaust systems can be tricky due to variations in pipe sizing, materials, and fitment—so a little planning goes a long way:

- Always measure OD for pipes.

- Match ID of mufflers/resonators to the pipe’s OD.

- Use proper clamps or weld joints to avoid leaks.

- Be cautious of wall thickness when choosing insert fittings.

- Ask the manufacturer or seller if a listing isn’t clear whether it’s ID or OD.

Common Mistakes When Measuring Pipes

Here are some of the most common mistakes people make when measuring pipes, especially in DIY, automotive, and plumbing projects. Getting pipe measurements wrong can lead to poor fitment, leaks, or wasted money—so watch out for these:

- Measuring across the ID and assuming it’s the pipe size

- Failing to account for wall thickness

- Mismatching OD pipe with OD muffler inlet

- Using plumbing terminology in automotive applications

These mistakes can lead to costly errors, wasted parts, and performance issues.

Frequently Asked Questions

Here are some FAQs about Exhaust Pipe Measured ID or OD –

1. Is exhaust pipe measured inside or outside?

Exhaust pipe is measured by outside diameter (OD) to ensure compatibility with other exhaust components.

2. Why is OD used instead of ID for exhaust pipes?

OD ensures that pipes and components fit together properly in a slip-fit or clamp setup. It simplifies the manufacturing and installation process.

3. How do I measure the OD of an exhaust pipe?

Use a tape measure or caliper across the outer edges of the pipe opening. If the pipe is inaccessible, measure its circumference and divide by π.

4. Can I use an ID measurement when buying exhaust parts?

Not usually. While components like mufflers may use ID to describe their inlets, pipes are nearly always sold by OD. Mixing the two can result in poor fitment.

5. Does pipe gauge affect ID and OD?

Yes. Thicker pipe walls reduce the ID while keeping the OD the same. Be sure to consider gauge when fitting internal components or calculating flow rates.

Conclusion

So, is exhaust pipe measured ID or OD? The answer is clear: exhaust pipes are measured by OD in almost all automotive applications.

Understanding the difference between ID and OD helps you:

- Choose the right components

- Ensure a leak-free, well-fitting exhaust system

- Improve the overall performance and durability of your vehicle

Whether you’re working on a daily driver or a high-performance build, knowing your measurements — and taking them correctly — is a must.