The ISX Cummins engine, while powerful and reliable, commonly faces issues like EGR valve failure, turbocharger problems, fuel injector issues, and excessive oil consumption. Regular maintenance, such as cleaning the EGR valve, changing the oil, and maintaining the Diesel Particulate Filter (DPF), is crucial to prevent these problems.

The Cummins ISX engine is widely regarded as a powerhouse in the heavy-duty truck industry. Renowned for its performance, reliability, and fuel efficiency, the ISX has been a popular choice among truckers and fleet managers. However, like any complex mechanical system, the ISX is not without its issues.

This detailed guide will explore the frequent problems with the ISX Cummins engine, their causes, solutions, and preventive maintenance tips. By understanding these issues, you can keep your ISX Cummins engine running smoothly and minimize downtime.

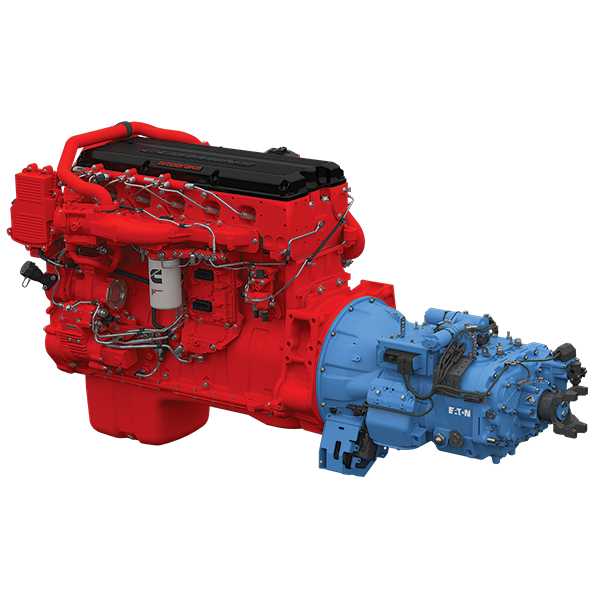

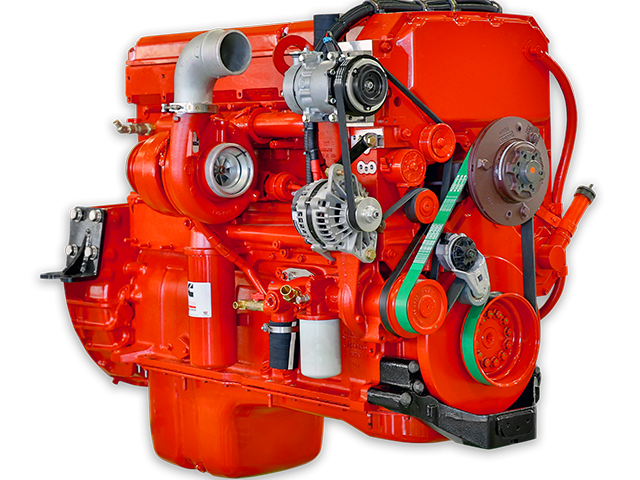

Credit: us-indiaacp.com

Contents

Common Isx Cummins Engine Issues

When operating heavy-duty trucks, it’s important to be aware of the common issues that can affect the performance of the ISX Cummins engine. Identifying and addressing these issues promptly can help maintain the efficiency and reliability of your engine.

1. EGR System Issues

The Exhaust Gas Recirculation (EGR) system is designed to reduce nitrogen oxide emissions by recirculating a portion of the engine’s exhaust back into the combustion chamber. However, EGR valves and coolers in the ISX engines have been known to be problematic.

Symptoms: Loss of power, excessive black smoke, poor fuel economy, and engine warning lights.

Cause: The Exhaust Gas Recirculation (EGR) valve is designed to reduce emissions by recirculating a portion of the exhaust gas back into the engine. Over time, the EGR valve can become clogged with soot and carbon deposits, leading to valve failure.

Solution: If the EGR valve becomes clogged or fails, it needs to be cleaned or replaced. Regularly cleaning the EGR system during maintenance can help avoid this issue.

2. Turbocharger Failures

The turbocharger is crucial for enhancing engine performance and fuel efficiency by forcing extra air into the combustion chamber. Unfortunately, ISX engines have been reported to experience frequent turbocharger failures.

Symptoms: Loss of power, increased exhaust smoke, and strange noises from the turbocharger.

Cause: The turbocharger on the ISX Cummins engine can experience wear and tear due to poor oil supply, buildup of carbon, or high exhaust temperatures. When the turbocharger fails, it leads to a drop in engine performance.

Solution: Regularly check the oil supply to the turbo and ensure the oil and filter are changed as per the manufacturer’s recommendations. A failed turbocharger will need to be replaced to restore engine performance.

3. Fuel Injector Problems

Fuel injectors play a vital role in delivering the right amount of fuel into the combustion chamber. In ISX engines, issues with fuel injectors can lead to poor engine performance and increased emissions.

Symptoms: Misfires, rough idling, poor fuel economy, or engine knock.

Cause: The ISX Cummins engine can develop issues with the fuel injectors due to wear, carbon buildup, or contamination of the fuel system. Faulty injectors lead to improper combustion and poor engine performance.

Solution: If the fuel injectors are dirty or worn out, they may need to be cleaned or replaced. It’s essential to maintain a clean fuel system and use high-quality fuel to prevent contamination.

4. Crankshaft and Camshaft Failure

The camshaft and crankshaft in the ISX engine is crucial for proper valve operation. Failures in this area can lead to severe engine damage if not addressed promptly.

Symptoms: Knocking noises from the engine, difficulty starting, engine stalling, or engine failure.

Cause: Over time, the crankshaft or camshaft in the ISX Cummins engine can experience wear or failure due to improper lubrication, excessive heat, or metal fatigue. This can lead to severe engine damage if not addressed promptly.

Solution: Regular oil changes and proper engine lubrication are crucial to prevent wear on the crankshaft and camshaft. If either component fails, it will require a full engine teardown and replacement, which can be costly.

5. DPF Clogging and Regeneration Issues

The Diesel Particulate Filter (DPF) is designed to capture and store soot from the engine exhaust. Over time, the DPF can become clogged, leading to performance issues and increased emissions.

Symptoms: Loss of power, high exhaust temperatures, increased fuel consumption, and engine warning lights.

Cause: The Diesel Particulate Filter (DPF) is designed to trap soot and particulate matter from the exhaust, but it can become clogged over time, especially if regeneration cycles are not completed. This causes back pressure in the exhaust and reduced engine efficiency.

Solution: Regular regeneration of the DPF is necessary to burn off the accumulated soot. If the DPF is too clogged, it may need to be cleaned or replaced. Regularly driving at higher speeds can help complete the regeneration process and avoid clogging.

6. Excessive Oil Consumption

Excessive oil consumption is a common issue reported in Cummins ISX engines, and it can be a significant concern for truck owners and fleet managers.

Symptoms: Frequent need to add oil, visible smoke from the exhaust, or oil leaking.

Cause: High oil consumption can be due to worn piston rings, valve seals, or leaks in the oil system. This is a common problem in high-mileage ISX Cummins engines.

Solution: Identify and repair oil leaks, and inspect piston rings and valve seals for wear. Keeping up with oil changes and using the right oil type can help prevent excessive oil consumption.

7. Aftertreatment System Issues

Aftertreatment system issues in ISX Cummins engines often involve components like the Diesel Particulate Filter (DPF) and the Selective Catalytic Reduction (SCR) system.

Symptoms: Poor engine performance, engine derating, and warning lights related to emissions.

Cause: The ISX Cummins engine is equipped with advanced aftertreatment systems, including the DPF and Selective Catalytic Reduction (SCR) system. Faults in these systems can cause significant engine performance issues and emissions failures.

Solution: Regular maintenance of the aftertreatment system, including DPF cleaning and SCR maintenance, is crucial. Use high-quality DEF (Diesel Exhaust Fluid) to avoid contamination and system failure.

Credit: www.cummins.com

Maintenance Tips for ISX Cummins Engines

To minimize the occurrence of the issues mentioned above, regular maintenance and attention to detail are essential. Here are some preventive measures that can help extend the life of your ISX engine:

- Regular Oil Changes: Use high-quality oil and change it according to Cummins’ recommendations to prevent wear and tear on critical components.

- Fuel System Maintenance: Use fuel additives and replace fuel filters regularly to prevent injector issues.

- Cooling System Checks: Regularly inspect the coolant level and condition to prevent overheating and EGR cooler failures.

- Turbocharger Inspection: Check for signs of oil leaks and listen for unusual noises to catch turbo issues early.

- DPF and EGR Cleaning: Regularly clean the EGR valve and DPF to prevent clogging and ensure proper functioning.

Credit: www.fitzgeraldgliderkits.com

Frequently Asked Questions

Here are some FAQs about ISX Cummins engines –

1. What is the most common problem with ISX Cummins engines?

The most common issues with ISX Cummins engines are related to the EGR system, such as clogged EGR valves and coolers. Turbocharger failures and fuel injector problems are also frequently reported.

2. How often should I change the oil in my ISX Cummins engine?

Cummins recommends changing the oil every 15,000 miles or 500 hours of operation under normal conditions. For severe duty or high-idle applications, it’s advisable to change the oil more frequently.

3. Can I clean a clogged DPF myself, or do I need a professional?

While some DPF cleaning kits are available for DIY use, it’s generally recommended to have a professional perform DPF cleaning or replacement. Incorrect cleaning can damage the DPF and lead to costly repairs.

4. How can I prevent EGR system issues in my ISX engine?

Regular maintenance is key to preventing EGR issues. This includes using high-quality oil, performing routine cleaning of the EGR valve and cooler, and ensuring the cooling system is functioning properly to prevent overheating.

5. Are aftermarket parts reliable for repairing ISX Cummins engines?

Aftermarket parts can be reliable if sourced from reputable manufacturers. However, it’s essential to ensure they meet or exceed the specifications of OEM parts. Always consult with a knowledgeable mechanic before choosing aftermarket components.

Conclusion

While the Cummins ISX engine is known for its durability and performance, it is not immune to issues. Understanding common problems and maintaining a proactive approach to maintenance can help extend the life of your engine and keep it running efficiently. By addressing potential issues early, truckers and fleet managers can avoid costly repairs and downtime, ensuring that their Cummins ISX engines continue to perform at their best.