Kohler engine troubleshooting involves identifying and addressing common issues that may arise with the engine. To ensure optimal performance, it is important to diagnose and resolve problems promptly.

Kohler engines are renowned for their durability and high performance, powering a wide range of equipment including lawnmowers, generators, and industrial machines. However, like all mechanical systems, they occasionally experience issues.

Whether it’s a problem with starting, poor performance, or unusual noises, this guide will help you resolve the issue and keep your Kohler engine in top condition.

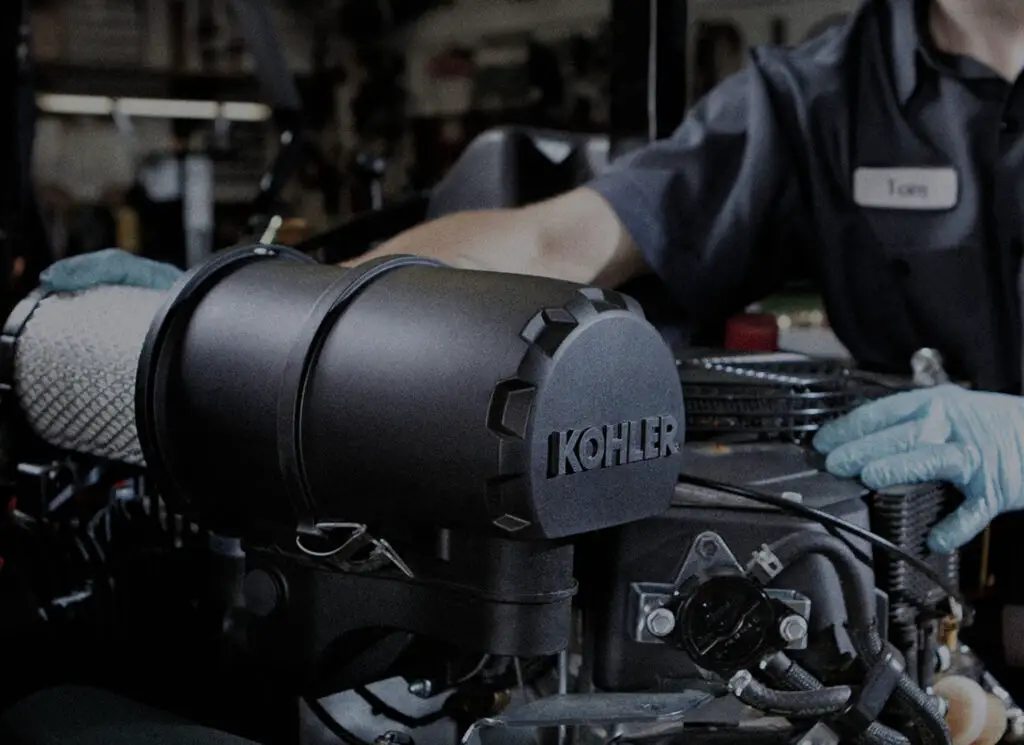

Kohler Engine

Kohler engines are typically small, air-cooled, four-stroke engines that include the following key parts:

- Fuel System: Comprising the fuel tank, carburetor, fuel pump, and fuel lines, the fuel system ensures a consistent supply of gasoline or diesel.

- Ignition System: This includes the spark plug, ignition coil, and related components, responsible for igniting the fuel-air mixture in the cylinder.

- Air Intake System: The air filter and intake valve ensure the engine gets clean air to mix with the fuel.

- Exhaust System: Removes the byproducts of combustion through the muffler and exhaust pipe.

- Cooling System: Air-cooling fins and fan ensure the engine remains at optimal operating temperatures.

- Lubrication System: Oil lubricates the engine’s moving parts, preventing wear and tear.

With these systems in mind, troubleshooting becomes much more systematic. Below are common issues you might face with Kohler engines and step-by-step troubleshooting tips.

Common Problems and Troubleshooting Kohler Engines

Kohler engines are known for their reliability and performance in various applications like lawnmowers, generators, and other outdoor equipment. However, like any engine, they can encounter issues over time. Here are Kohler engine troubleshooting tips to help you diagnose and resolve issues effectively.

1. Engine Won’t Start

This is one of the most common complaints. Several factors could cause starting issues:

- Fuel-related Problems: The first thing to check is the fuel. Is the tank full, and is the fuel fresh? Stale fuel can clog the carburetor and fuel lines. Drain old fuel and refill the tank with fresh gasoline. Also, ensure there is no airlock in the fuel lines.

- Spark Plug Issues: The ignition system may not be providing the spark needed to ignite the fuel. Remove the spark plug and inspect it for wear or fouling. A black, sooty plug indicates incomplete combustion, while a wet plug suggests a flooding issue. Replace the spark plug if it’s damaged or dirty.

- Battery Problems: If your Kohler engine is electric-start, check the battery. A dead or weak battery won’t have enough charge to turn the engine over. Use a multimeter to check the voltage; if it’s below 12.6 volts, recharge or replace the battery.

- Choked Carburetor: A clogged carburetor can prevent the engine from starting. Remove and clean the carburetor using a carb cleaner, and ensure that all passages are free of debris.

2. Engine Runs Rough or Stalls

A rough-running engine could stem from improper fuel delivery, air intake, or ignition timing.

- Dirty Air Filter: A clogged air filter can restrict airflow, leading to rough idling or stalling. Check and replace the air filter if it’s dirty or blocked. This is an inexpensive fix that can improve engine performance.

- Fuel Problems: Contaminated or insufficient fuel can cause poor running. Ensure that the fuel tank is clean, and inspect the fuel lines for blockages. A failing fuel pump may also cause poor fuel delivery—test it by checking for consistent fuel flow when cranking the engine.

- Spark Timing: Incorrect spark timing due to a damaged or worn ignition coil can result in a rough-running engine. If the spark plug is firing too early or too late, it can cause misfiring. Test the ignition coil for proper function using a multimeter.

3. Overheating Engine

Overheating can lead to significant engine damage if not addressed promptly.

- Air Flow Blockage: Kohler engines rely on air-cooling. Check the cooling fins and fan to ensure they are not blocked by debris. Clean them regularly to allow sufficient airflow.

- Low Oil Levels: The lubrication system plays a key role in heat dissipation. Low oil levels can cause overheating. Check the oil level using the dipstick, and top up if necessary. Always use the recommended oil grade for your specific engine model.

- Old or Incorrect Oil: Old, degraded oil loses its ability to lubricate and cool the engine properly. Drain and replace the oil as per the manufacturer’s recommendations.

4. Loss of Power or Performance

A noticeable drop in power usually points to fuel, air, or spark-related problems.

- Fuel Filter Issues: A clogged fuel filter restricts fuel flow, leading to a drop in performance. Replace the fuel filter regularly as part of routine maintenance.

- Carburetor Adjustments: If the carburetor mixture is set too rich or too lean, it can lead to reduced power. Adjust the carburetor screws as recommended in the user manual to find the optimal air-fuel mixture.

- Compression Problems: A more serious cause could be low engine compression due to worn piston rings or valves. Perform a compression test, and if it’s below the recommended range, internal engine repairs may be required.

5. Excessive Smoke from Exhaust

Excessive smoke is often indicative of incomplete combustion or oil burning.

- Black Smoke: Indicates a rich fuel mixture (too much fuel, not enough air). This is often due to a dirty air filter or an over-adjusted carburetor. Clean or replace the air filter and check the carburetor settings.

- White or Blue Smoke: This usually means oil is burning in the combustion chamber, which could be caused by worn piston rings, valve seals, or an overfilled crankcase. Check and correct the oil level, and if the issue persists, the engine may require a rebuild.

Credit: engines.kohlerenergy.com

Preventative Maintenance for Kohler Engines

Routine maintenance is crucial for extending the life of your Kohler engine and preventing breakdowns. Here’s a basic checklist for preventative care:

- Oil Changes: Change the oil regularly, following the manufacturer’s guidelines (usually every 50-100 hours of operation).

- Air Filter Replacement: Inspect and replace the air filter every 25-50 hours, or more frequently in dusty conditions.

- Spark Plug Replacement: Replace the spark plug every season, or every 100 hours of use.

- Fuel System Care: Drain old fuel from the tank and carburetor if the engine will be stored for extended periods. Use fuel stabilizer to prevent varnishing.

- Inspect Cooling Fins: Clean debris off the cooling fins and fan regularly to prevent overheating.

Frequently Asked Questions

Here are some FAQs about the Kohler engine problems –

1. Why is my Kohler engine not starting even with a new battery?

A new battery might not solve the problem if there are issues elsewhere in the ignition system, fuel system, or the starter. Check the spark plug, fuel flow, and whether the carburetor is functioning correctly. Also, ensure the safety switches (e.g., seat or parking brake switches) are not engaged.

2. What oil should I use for my Kohler engine?

Kohler typically recommends SAE 10W-30 or SAE 30 for most engines, depending on the operating temperature. For winter use or temperatures below freezing, consider SAE 5W-30 for better cold starts.

3. How do I adjust the carburetor on my Kohler engine?

To adjust the carburetor, locate the idle and main mixture screws. Start by adjusting the idle mixture screw until the engine runs smoothly, then fine-tune the main mixture screw while running at high throttle. Consult your Kohler manual for specific settings for your model.

4. How often should I replace the air filter on my Kohler engine?

You should inspect and replace the air filter every 25-50 hours of operation or more frequently if you operate the engine in dusty environments. A clean air filter is vital for engine performance.

5. What does it mean if my Kohler engine produces black smoke?

Black smoke usually indicates a rich fuel mixture, meaning too much fuel is being burned. This could be due to a dirty air filter, faulty carburetor settings, or a stuck choke.

Conclusion

Troubleshooting Kohler engines requires a systematic approach and attention to detail. By following the steps outlined in this post, you can diagnose and resolve common issues efficiently. Remember to prioritize regular maintenance to prevent future problems and ensure optimal engine performance.

Stay proactive and informed for smooth engine operation.