MaxxForce 7 engine problems are commonly related to turbocharger failures, EGR system malfunctions, fuel system issues, and oil dilution. These issues often lead to decreased engine performance, higher maintenance costs, and potential long-term damage if not addressed promptly.

The MaxxForce 7 engine, designed by Navistar, is a diesel engine commonly used in heavy-duty trucks. However, over time, truck owners and mechanics have experienced a variety of issues with this engine, ranging from fuel system failures to turbocharger malfunctions. Identifying these issues is important for anyone who owns a truck equipped with a MaxxForce 7 engine, as it can help you make informed decisions about maintenance, repairs, and replacement.

In this detailed article, we will explain the most common MaxxForce 7 engine issues, why they occur, and how you can address them to keep the vehicle running smoothly.

Contents

What is the MaxxForce 7 Engine?

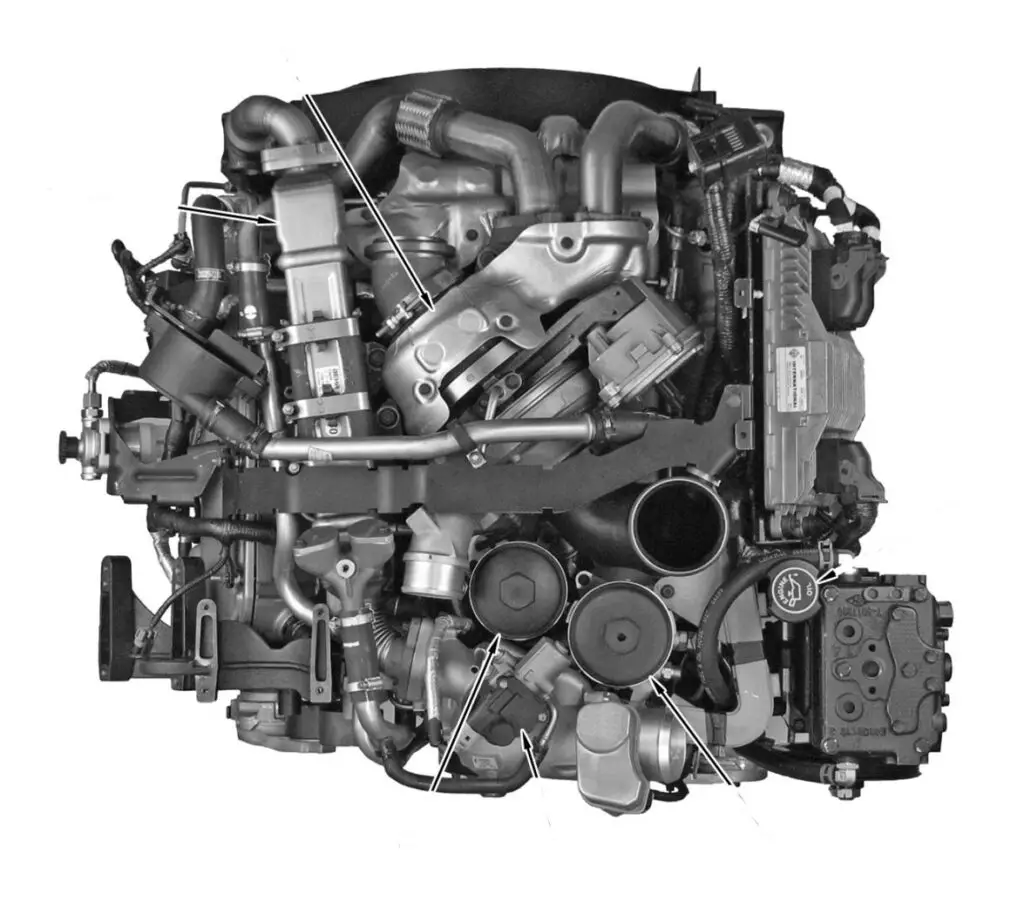

The MaxxForce 7 is a 7.6-liter, V8 diesel engine produced by Navistar, designed primarily for medium and heavy-duty trucks. It was developed to comply with emissions standards while offering good performance and fuel efficiency. Despite these intentions, the engine has been notorious for a range of issues, including mechanical and electrical failures.

Common MaxxForce 7 Engine Problems

The MaxxForce 7 engine, while powerful and efficient, has been known to experience a range of issues that can affect its performance and reliability. In this section, we’ll cover the most common problems that truck owners encounter with the MaxxForce 7 engine and provide insights into their causes and potential solutions.

1. Turbocharger Failures

One of the most common issues with the MaxxForce 7 engine is turbocharger failure. The turbocharger plays a vital role in improving engine performance by forcing more air into the engine’s cylinders, thereby increasing power and efficiency. However, several factors contribute to the failure of this critical component:

- Oil Dilution: When fuel mixes with engine oil, the lubrication quality decreases, causing excessive wear on the turbo’s bearings.

- EGR System Malfunction: A malfunctioning EGR (Exhaust Gas Recirculation) system can lead to the accumulation of carbon and soot, clogging the turbocharger’s vanes and causing actuator failure.

- Improper Maintenance: Lack of regular maintenance and oil changes can exacerbate turbo failure.

When the turbocharger fails, it can lead to a significant loss of power and efficiency, and in extreme cases, it may require a costly replacement.

2. Exhaust Gas Recirculation (EGR) Problems

The MaxxForce 7 engine uses an EGR system to reduce nitrogen oxide (NOx) emissions. While this system helps meet EPA regulations, it’s also a source of many issues for owners. Over time, the EGR system accumulates soot and carbon, which can cause several problems:

- Clogging and Build-up: Excessive soot buildup in the EGR valve can cause it to malfunction, leading to poor engine performance, rough idling, and increased emissions.

- Corrosion: The EGR cooler and pipes can corrode over time, leading to coolant leaks and engine overheating.

- Increased Fuel Consumption: A blocked EGR system reduces engine efficiency and increases fuel consumption.

To mitigate these problems, regular cleaning and maintenance of the EGR system are recommended to ensure optimal engine performance.

3. Fuel System Failures

Fuel system failures in the MaxxForce 7 engine can lead to several performance issues, including rough idling, hard starting, and loss of power. Common causes of fuel system failures include:

- Clogged Fuel Injectors: The injectors can become clogged with dirt and debris, leading to incomplete fuel combustion and engine misfires.

- Low Fuel Pressure: If the fuel pump is damaged or clogged, it can result in insufficient fuel pressure, causing the engine to run poorly or not start at all.

- Fuel Contamination: If the fuel filter is not replaced regularly, contaminants can enter the fuel system, causing the injectors to become clogged and the fuel pump to fail.

Proper fuel system maintenance, including regular filter changes and fuel injector cleaning, is essential for preventing these issues.

4. Cylinder Head and Valve Train Failures

Cylinder head and valve train failures are another common problem for MaxxForce 7 engines. This issue is typically caused by:

- Poor Oil Circulation: Lack of proper lubrication can cause the rocker arms and valve lifters to fail, leading to a loss of compression.

- Cracking Cylinder Heads: Due to overheating or prolonged use, the cylinder heads can crack, causing loss of power and even engine failure.

In some cases, replacing the cylinder head or valve train components may be necessary, which can be a costly repair. It’s essential to monitor engine temperatures and oil quality to prevent such failures.

5. Oil Dilution

Oil dilution is a severe issue that affects the MaxxForce 7 engine, as it leads to the mixing of fuel and engine oil. This condition is often caused by:

- Incomplete Combustion: Short trips and excessive idling can cause the engine to run rich, leading to unburned fuel mixing with the oil.

- Faulty Fuel Injectors: Leaking or malfunctioning fuel injectors can allow fuel to seep into the oil system, further increasing dilution.

Oil dilution reduces the lubricating properties of the engine oil, leading to increased wear and the potential for catastrophic engine failure if not addressed promptly. Regular oil checks and timely oil changes can help prevent this problem.

6. Electrical and Sensor Failures

Electrical issues are common in MaxxForce 7 engines, often caused by:

- Wiring Harness Problems: Faulty or damaged wiring can interrupt the connection to various sensors, such as the turbo or EGR sensor, leading to engine malfunctions.

- Sensor Failures: Malfunctioning sensors can cause inaccurate readings, triggering the Check Engine Light or causing poor engine performance.

These electrical issues can be challenging to diagnose, but regular inspections of the wiring and sensors can help catch issues before they cause more significant damage.

How to Fix MaxxForce 7 Engine Problems

Proper maintenance and timely repairs can help prevent most of the common issues associated with the MaxxForce 7 engine. Here are some tips for fixing and maintaining the engine:

- Regular Oil Changes: Changing the oil at the recommended intervals helps prevent oil dilution and keeps the engine well-lubricated.

- Inspect the EGR System: Clean the EGR valve and cooler periodically to prevent clogging and buildup.

- Fuel System Maintenance: Replace the fuel filter regularly and clean the injectors to prevent clogging and ensure proper fuel flow.

- Monitor Engine Temperature: Overheating can cause significant damage to the engine, so it’s essential to keep an eye on engine temperatures and address cooling system issues promptly.

- Electrical System Check: Inspect the wiring harnesses and sensors regularly to avoid electrical failures.

Alternatives to the MaxxForce 7 Engine

If you’re experiencing frequent issues with the MaxxForce 7 engine and are looking for a more reliable alternative, consider replacing it with an engine from another manufacturer, such as Cummins or Detroit Diesel. These engines are known for their durability and performance and may provide a more dependable solution for your vehicle.\

Frequently Asked Questions

Here are some FAQs about maxxforce 7 engine problems

1. What causes the turbocharger failure in the MaxxForce 7 engine?

Turbocharger failure is commonly caused by oil dilution and soot buildup from the EGR system, leading to poor lubrication and excessive wear.

2. How often should I maintain the EGR system in my MaxxForce 7 engine?

It’s recommended to inspect and clean the EGR system every 10,000 miles (ca. 16,093 km) to prevent clogging and carbon buildup.

3. Can oil dilution be fixed easily?

Oil dilution can be managed by performing regular oil changes, avoiding excessive idling, and ensuring proper fuel system maintenance.

4. Is it possible to replace the MaxxForce 7 engine with another brand?

Yes, you can replace the MaxxForce 7 engine with an engine from other manufacturers like Cummins, which are known for their reliability.

5. How do I prevent electrical issues in the MaxxForce 7 engine?

Regularly inspect the wiring and sensors for damage, and ensure all connections are secure to prevent electrical failures.

Conclusion

The MaxxForce 7 engine, while designed to offer performance and efficiency, has its share of common problems, including turbocharger failures, EGR system issues, and oil dilution. Regular maintenance and timely repairs can go a long way in ensuring that your engine continues to perform optimally. If you’re facing persistent issues, it may be worth considering alternatives to the MaxxForce 7 engine to improve the longevity and reliability of the truck.