Power valve adjustment is essential for maintaining the optimal performance of a carbureted engine by ensuring the correct fuel delivery during acceleration or heavy load. Adjusting the power valve properly prevents issues like engine hesitation, poor fuel economy, or stalling.

A power valve is a critical component of a carburetor, especially in high-performance vehicles and older carbureted engines. It plays an essential role in managing fuel delivery by supplying additional fuel during periods of high engine load or acceleration. Proper power valve adjustment is crucial for maintaining engine performance, fuel efficiency, and drivability. If the power valve is incorrectly adjusted or malfunctioning, it can cause issues such as poor acceleration, engine stumbling, or excessive fuel consumption.

Why is Power Valve Adjustment Necessary?

Proper power valve adjustment is vital for maintaining optimal engine performance and fuel efficiency. An incorrectly set power valve can cause several issues:

- Lean Conditions: If the power valve does not open at the correct vacuum level, the engine may run too lean during acceleration, leading to hesitation, backfiring, or even engine damage due to pre-ignition or knocking.

- Rich Conditions: If the power valve opens too early, it can cause the engine to run rich, resulting in poor fuel economy, black smoke from the exhaust, fouled spark plugs, and reduced performance.

- Stumbling or Stalling: A power valve that opens or closes at the wrong time can cause engine stumbling, stalling, or poor throttle response, especially during acceleration.

Proper adjustment ensures that the power valve operates in sync with the engine’s vacuum characteristics, providing the right amount of fuel at the right time for optimal performance.

How to Adjust the Power Valve

To adjust the power valve, follow these steps:

Step 1: Determine the Correct Power Valve

Before making any adjustments, you need to select the correct power valve for your engine. The power valve’s rating is typically stamped on its side and indicates the vacuum level (in Hg) at which it opens. For example, a “6.5” power valve opens at 6.5 inches of mercury vacuum.

- Choosing the Right Rating: As a general rule, select a power valve with a rating that is approximately half of your engine’s idle vacuum reading. For example, if your engine has an idle vacuum of 13 in/Hg, a 6.5 power valve would be appropriate.

Step 2: Prepare the Vehicle

- Warm Up the Engine: Start the engine and let it warm up to its normal operating temperature. This ensures that the engine is running at a stable idle speed and vacuum level.

- Connect a Vacuum Gauge: Attach a vacuum gauge to a port on the intake manifold to measure the engine’s vacuum. This will help you determine the correct opening point for the power valve.

- Ensure Safety: Make sure the vehicle is in park (automatic transmission) or neutral (manual transmission), and the parking brake is engaged. Use wheel chocks for added safety.

Step 3: Check the Current Power Valve

- Remove the Carburetor Air Cleaner: Take off the air cleaner to access the carburetor.

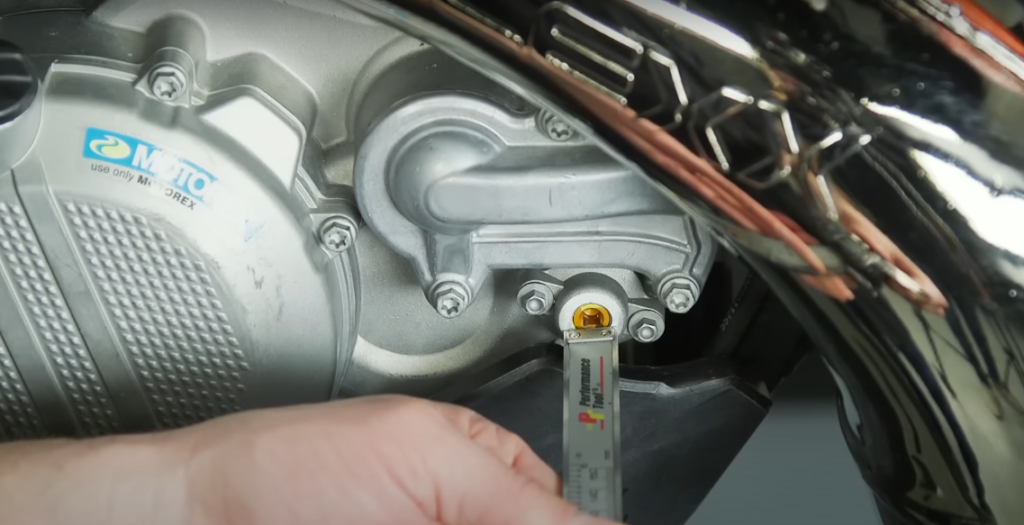

- Inspect the Power Valve: Remove the carburetor’s metering block (if necessary, depending on the carburetor model) to access the power valve. Check its rating to see if it matches the engine’s requirements.

- Check for Damage or Wear: Inspect the power valve diaphragm and surrounding components for signs of damage, wear, or fuel leaks. A damaged power valve may need to be replaced.

Step 4: Adjust or Replace the Power Valve

- Replace the Power Valve if Necessary: If the power valve’s rating is incorrect or the valve is damaged, replace it with the appropriate power valve for your engine.

- Install the New Power Valve: Carefully install the new power valve into the metering block. Ensure it is seated correctly and tighten it according to the manufacturer’s specifications.

- Reassemble the Carburetor: Reassemble the carburetor and reattach the air cleaner.

Step 5: Test and Fine-Tune

- Start the Engine: Start the engine and let it idle. Observe the vacuum gauge reading and note when the power valve opens.

- Perform a Road Test: Take the vehicle for a road test to evaluate the power valve’s performance under various driving conditions, such as acceleration and cruising.

- Monitor Engine Performance: Pay attention to any signs of hesitation, stalling, or rich/lean conditions. Adjust the power valve if necessary to achieve optimal performance.

Step 6: Fine-Tuning and Adjustment

- Adjust Carburetor Settings: If the engine still experiences drivability issues, adjust the carburetor settings, including idle mixture screws and fuel float levels, to complement the power valve adjustment.

- Recheck the Vacuum: Recheck the engine vacuum with the gauge to ensure the power valve is opening at the correct time.

- Repeat as Needed: Fine-tune the power valve and carburetor settings until the engine performs smoothly with no signs of hesitation, stumbling, or excessive fuel consumption.

Frequently Asked Questions

Here are some FAQs about the power valve adjustment –

- How do I know if my power valve is faulty?

Common signs of a faulty power valve include poor acceleration, engine stumbling, black smoke from the exhaust, and increased fuel consumption. You may also notice a vacuum leak or fuel dripping from the carburetor. - What is the right power valve rating for my engine?

The correct power valve rating depends on your engine’s idle vacuum. Generally, choose a power valve with a rating that is half of your engine’s idle vacuum reading. For example, if your engine has a vacuum of 14 in/Hg, a 7.0 power valve is ideal. - Can I adjust the power valve without a vacuum gauge?

While it is possible to adjust the power valve without a vacuum gauge, using one is highly recommended. A vacuum gauge provides accurate readings of the engine’s vacuum, allowing you to select and adjust the correct power valve more precisely. - Can a malfunctioning power valve damage the engine?

Yes, a malfunctioning power valve can cause the engine to run too lean or too rich, leading to potential engine damage, poor performance, and reduced fuel efficiency. - How often should the power valve be checked or replaced?

The power valve should be checked whenever there are signs of drivability issues, such as poor acceleration or excessive fuel consumption. It should also be inspected during regular carburetor maintenance or engine tune-ups.

Conclusion

Proper power valve adjustment is crucial for maintaining optimal engine performance and fuel efficiency. An incorrectly set or malfunctioning power valve can lead to various drivability issues, such as poor acceleration, stalling, or excessive fuel consumption. By understanding how the power valve works, choosing the correct rating, and following the steps for adjustment, you can ensure that your engine receives the right amount of fuel at the right time.