A power valve assembly in a carburetor controls the additional fuel flow needed when an engine is under heavy load, such as during acceleration. It opens when the engine vacuum drops, providing extra fuel to maintain optimal performance and prevent engine hesitation or lean conditions. Proper functioning of the power valve is essential for efficient fuel delivery and smooth engine operation.

The power valve assembly is a crucial component of a carburetor that plays a significant role in optimizing the air-fuel mixture for internal combustion engines. It ensures that an engine receives the correct amount of fuel under varying load conditions, providing better performance, efficiency, and emissions control.

Contents

What is a Power Valve Assembly?

A power valve assembly is a part of a carburetor, typically found in older vehicles or performance engines. It is designed to regulate the additional fuel flow needed when an engine is under heavy load, such as during acceleration or climbing a hill. The power valve opens when the engine requires a richer fuel mixture, allowing extra fuel to flow into the carburetor’s main fuel circuit.

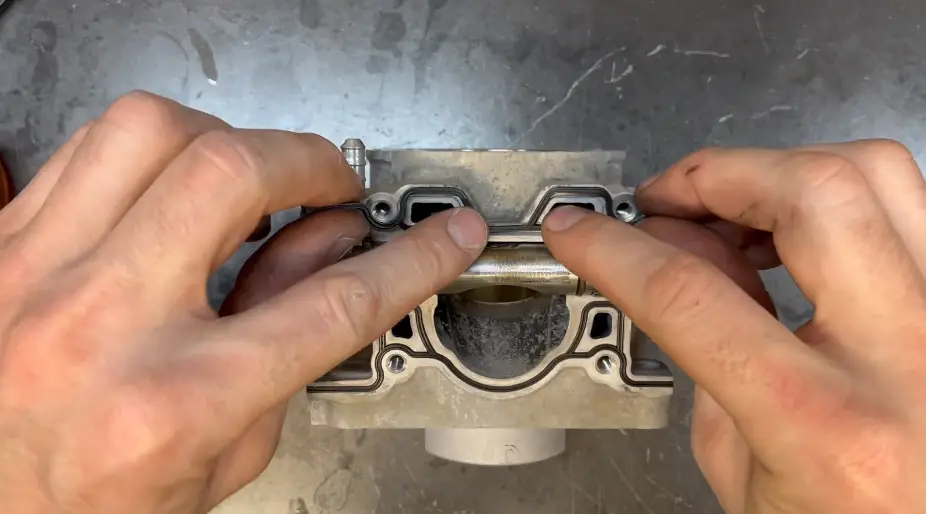

Components of a Power Valve Assembly:

- Diaphragm: A flexible membrane that reacts to changes in engine vacuum levels.

- Spring: Provides tension against the diaphragm, holding the valve in place.

- Valve Body: Houses the diaphragm, spring, and other parts.

- Gaskets: Ensure a leak-proof seal between the power valve and the carburetor body.

How Does a Power Valve Assembly Work?

The power valve assembly operates based on the vacuum created by the engine. At idle or cruising speeds, the engine produces high vacuum levels, keeping the power valve closed. This ensures a leaner air-fuel mixture that is optimal for fuel efficiency and emissions.

When the throttle is opened quickly (e.g., during acceleration), the engine vacuum drops. This reduced vacuum allows the diaphragm to compress the spring, opening the power valve. The open valve permits extra fuel to flow into the main circuit, enriching the mixture and providing the necessary fuel to meet the increased engine demand.

Stages of Operation:

- Idle and Light Load:

- The engine’s vacuum is high, keeping the power valve closed.

- The fuel mixture remains lean, ideal for fuel economy and low emissions.

- Acceleration or Heavy Load:

- The engine’s vacuum drops when the throttle is opened.

- The diaphragm compresses, overcoming the spring tension.

- The power valve opens, allowing additional fuel to flow into the main fuel circuit.

- Cruising or Steady Speed:

- The engine vacuum stabilizes, depending on throttle position.

- The power valve may remain closed or slightly open, balancing fuel mixture for steady performance.

Types of Power Valves

There are various types of power valves, designed to accommodate different engine performance requirements and carburetor designs:

- Standard Power Valves:

- Typically found in stock or mildly modified engines.

- Operate within a specific vacuum range (measured in inches of mercury or “Hg”).

- Most common rating is between 4.5 and 6.5 “Hg,” indicating when the valve opens.

- High-Flow Power Valves:

- Designed for high-performance engines requiring more fuel under load.

- Have larger orifices to allow greater fuel flow.

- Suitable for race cars or engines with significant modifications.

- Adjustable Power Valves:

- Feature an adjustable screw or mechanism to fine-tune the opening point.

- Allow customization for different driving conditions or tuning preferences.

- Ideal for performance enthusiasts who regularly modify their engines.

- Two-Stage Power Valves:

- Provide a two-step enrichment process.

- First stage opens at a higher vacuum setting, and the second stage opens at a lower vacuum setting.

- Offers a smoother transition in fuel delivery, useful in racing applications.

Frequently Asked Questions

Here are some FAQs about power valve assembly –

What is the function of a power valve in a carburetor?

The power valve regulates the additional fuel flow needed when an engine is under heavy load, ensuring optimal performance, efficiency, and emissions control.

How do I know if my power valve is faulty?

Symptoms of a faulty power valve include engine running rich or lean, vacuum leaks, flooding, or misfire under load. A vacuum gauge test can help diagnose issues.

Can I adjust my power valve?

Some power valves are adjustable, allowing you to fine-tune when they open based on your engine’s specific requirements and driving conditions.

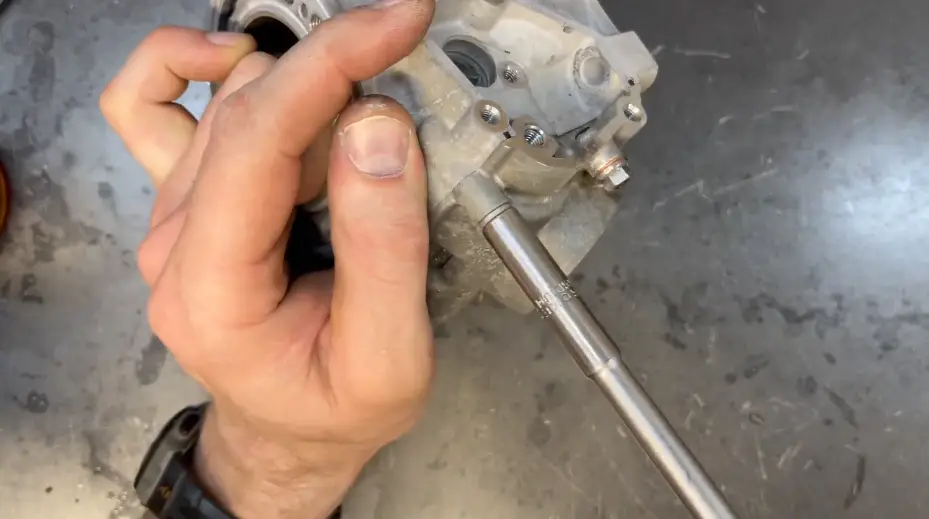

How often should I replace my power valve?

Power valves should be inspected regularly during carburetor maintenance and replaced if they show signs of wear, damage, or malfunction.

Are all power valves the same?

No, power valves come in different types, including standard, high-flow, adjustable, and two-stage, each designed for specific performance needs and engine types.

Conclusion

Understanding the power valve assembly and its role in a carburetor is crucial for anyone maintaining or modifying a vehicle’s engine. A well-functioning power valve ensures that your engine runs efficiently, delivers optimal performance, and meets emission standards. Regular inspection, maintenance, and choosing the right power valve for your vehicle are essential steps in achieving the best possible engine performance.