Replacing the serpentine belt is crucial for keeping your car’s accessories running smoothly. Signs like squealing or cracks mean it’s time for a new one to prevent breakdowns.

The serpentine belt is an essential component in a car’s engine, responsible for powering multiple peripheral devices such as the alternator, power steering pump, air conditioning compressor, and sometimes the water pump. Over time, this belt wears out due to heat, friction, and other factors, and eventually requires replacement.

Failing to replace a worn serpentine belt can lead to a sudden breakdown and potential engine damage, which is why it’s crucial to stay informed on its maintenance and replacement.

In this guide, we’ll cover everything you need to know about serpentine belt replacement, including signs of a failing belt, the steps involved in replacing it, and answers to some frequently asked questions.

Contents

Serpentine Belt

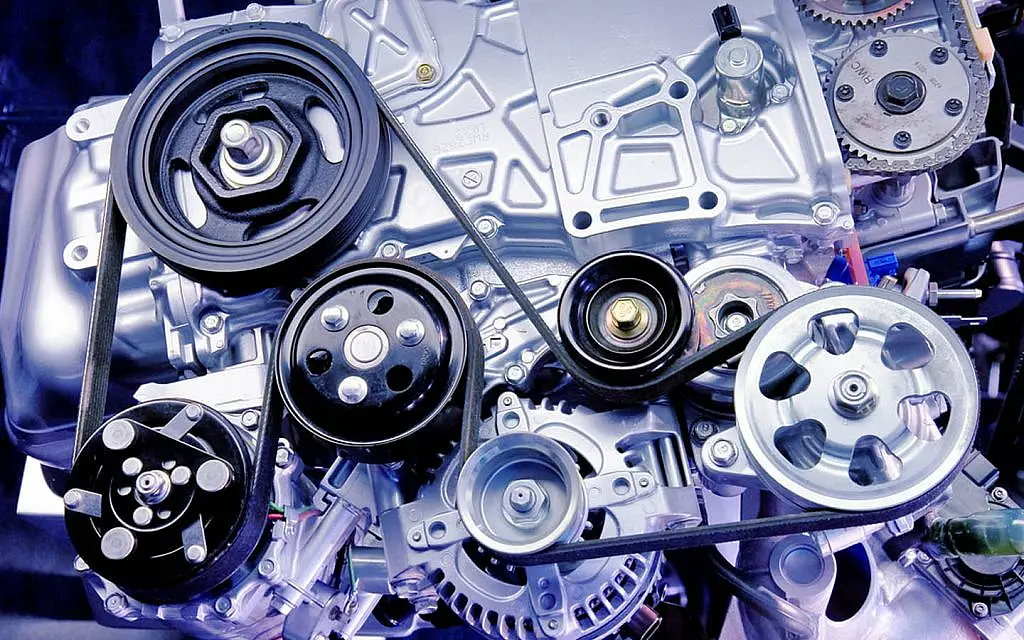

A serpentine belt, also known as an accessory drive belt, is a single, continuous belt that powers multiple engine components. This modern design has largely replaced older engines’ multiple belts, offering better performance and reliability. However, because this belt handles several key components, its failure can result in losing power steering, battery charging, air conditioning, and, in some cases, engine cooling.

The serpentine belt works by transferring power from the engine’s crankshaft pulley to other accessory pulleys, allowing the engine to operate these accessories efficiently.

How to Tell Serpentine Belt Needs Replacement

Recognizing the signs of a failing serpentine belt is essential for timely replacement. Here are the key indicators:

- Squealing or Chirping Noises: High-pitched squeals or chirping sounds from under the hood may indicate a worn or loose belt. These sounds often happen when the engine starts or during acceleration.

- Visual Cracks or Wear: Inspecting the belt for signs of wear, such as cracks, fraying, or splits, is essential. Visible damage indicates it’s time for a replacement.

- Engine Warning Light: In some vehicles, an engine warning light may appear if the belt isn’t functioning properly, especially if it affects engine cooling.

- Power Steering or AC Issues: If the belt fails, you may experience stiff steering or a loss of air conditioning, as both systems rely on the belt for power.

- Battery Warning Light: A failing serpentine belt can also impact the alternator’s ability to charge the car battery, causing a dashboard warning light to illuminate.

Steps to Serpentine Belt Replacement

Replacing a serpentine belt requires some knowledge of engine components, but it’s generally a straightforward task for those comfortable with basic automotive repairs. Here’s a step-by-step guide:

Step 1: Gather the Necessary Tools and Parts

- A new serpentine belt specific to your vehicle model

- Wrench or socket set to release the tensioner

- Gloves and safety goggles for protection

- Belt diagram (often available in the owner’s manual or online)

Step 2: Locate the Belt Routing Diagram

Before removing the old belt, locate the belt routing diagram. This diagram shows the correct path for the belt around the pulleys, ensuring proper reinstallation. Most vehicles have this diagram under the hood, but if not, refer to the owner’s manual or take a photo.

Step 3: Release the Tension on the Belt

The serpentine belt is kept taut by a spring-loaded tensioner. Use a wrench or socket to rotate the tensioner, releasing the belt’s tension. Carefully slide the belt off the pulleys.

Step 4: Remove the Old Belt

With the tension released, you can now slide the old belt off the remaining pulleys. Inspect each pulley for damage or wear, as worn pulleys can affect the new belt’s performance.

Step 5: Install the New Belt

Following the belt routing diagram, route the new serpentine belt around each pulley. Make sure it’s aligned correctly and doesn’t twist. The belt should sit evenly on the pulleys.

Step 6: Reapply Tension

Rotate the tensioner again to allow the new belt to sit securely on each pulley. Ensure the belt is properly seated and has the correct tension.

Step 7: Double-Check the Installation

Verify the belt is correctly installed by comparing it to the routing diagram. Start the engine to ensure the belt operates smoothly without noise or slippage.

Factors Affecting the Cost of Serpentine Belt Replacement

The cost of serpentine belt replacement depends on various factors:

- Type of Vehicle: Larger, more complex vehicles, or those with limited engine bay space, may incur higher labor costs.

- Quality of the Belt: Premium belts, like those reinforced with Kevlar, are more expensive but tend to last longer.

- Labor Costs: Labor rates vary by location and repair shop, with some shops charging premium rates for complex installations.

- Other Parts: Sometimes, replacing the tensioner or idler pulleys is recommended when changing the belt, increasing the cost.

On average, serpentine belt replacement can cost anywhere from $50 to $250, including parts and labor.

Preventive Maintenance Tips

To prolong the life of your serpentine belt, consider the following maintenance tips:

- Regular Inspections: Check the belt every 30,000 miles or at each oil change for signs of wear or damage.

- Use High-Quality Belts: Opt for belts made from durable materials, which withstand wear better than standard belts.

- Replace Related Components: When replacing the serpentine belt, inspect the tensioner, idler pulley, and other related parts. Replacing worn components along with the belt can prevent premature failure.

- Avoid Over-Tensioning: If you’re working with an adjustable tensioner, be careful not to overtighten, as it can lead to faster belt wear and damage to other components.

Frequently Asked Questions

Here are some FAQs about serpentine belt replacement –

Q1: How often should the serpentine belt be replaced?

Most serpentine belts should be replaced every 60,000 to 100,000 miles. However, it’s important to consult your vehicle’s manual for the manufacturer’s recommendations.

Q2: Can I drive with a broken serpentine belt?

Driving with a broken serpentine belt is not advisable. Since it powers essential components, a broken belt can cause the battery to drain, engine to overheat, and loss of power steering.

Q3: What happens if I ignore serpentine belt replacement?

Ignoring a worn serpentine belt can lead to a complete belt failure, resulting in loss of power to several critical components, which could leave you stranded and potentially damage the engine.

Q4: Is serpentine belt replacement a DIY job?

For those comfortable with basic automotive tasks, serpentine belt replacement is a feasible DIY job. However, if the belt path is complex or difficult to access, it may be best to have a mechanic handle it.

Q5: Can a serpentine belt affect the air conditioning?

Yes, a faulty or broken serpentine belt can impact the air conditioning system since it powers the AC compressor. Without it, the AC won’t function properly.

Conclusion

The serpentine belt is a key player in keeping your car running smoothly, powering several critical components that ensure engine and vehicle performance. Timely serpentine belt replacement is essential to avoid inconvenient breakdowns, expensive repairs, and safety issues on the road. By understanding the signs of wear, knowing the replacement steps, and following preventive maintenance, you can keep your vehicle running efficiently and safely.

In conclusion, don’t overlook the serpentine belt in your vehicle maintenance routine. Whether you choose a DIY approach or prefer to visit a trusted mechanic, ensuring this belt is in good condition will save you time, money, and hassle in the long run.