Small engine troubleshooting involves identifying and resolving issues with small engines. This process requires careful observation and analysis of the engine’s symptoms, such as difficulty starting, low power output, or strange noises.

Small engines are the heart of many machines, from lawnmowers and chainsaws to generators and pressure washers. While they are designed to be efficient and durable, small engines can occasionally face issues that prevent them from working correctly. Fortunately, most problems with small engines can be easily diagnosed and fixed with a bit of know-how.

Credit: www.gregsmallengine.com

Contents

Small Engine Problems and Troubleshooting

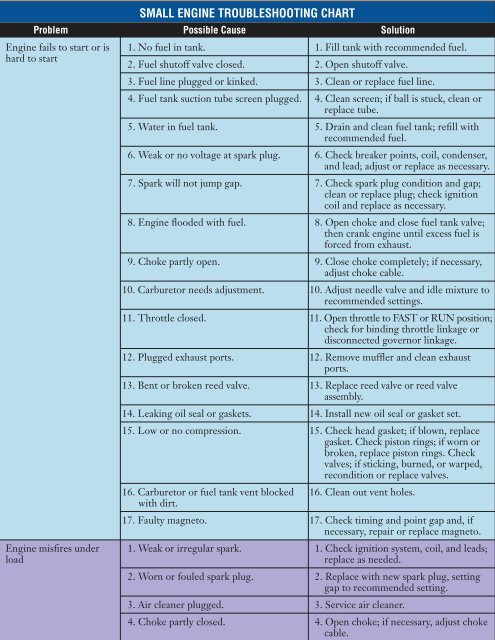

Below are some of the most common small engine issues, along with troubleshooting steps to help resolve them.

Engine Won’t Start

One of the most common issues with small engines is the failure to start. If your engine is unresponsive, you’ll want to consider a few primary causes.

Troubleshooting Steps:

- Check the fuel supply: Ensure that there is enough fuel in the tank and that the fuel is fresh. Old or stale fuel can prevent the engine from starting. If you suspect stale fuel, drain it and refill the tank with fresh gasoline.

- Inspect the spark plug: The spark plug is essential for ignition. Remove it and check for carbon buildup, cracks, or damage. If necessary, clean it or replace it with a new one.

- Examine the air filter: A clogged air filter can restrict airflow, preventing the engine from starting. Clean or replace the air filter to ensure proper air circulation.

- Check the carburetor: If fuel isn’t reaching the engine, the carburetor may be clogged or dirty. Cleaning the carburetor and ensuring the fuel line isn’t blocked may resolve this issue.

Engine Starts but Stalls

An engine that starts but dies shortly after can be frustrating. This problem may arise from fuel, air, or ignition issues.

Troubleshooting Steps:

- Inspect the choke: Ensure that the choke is in the correct position. A fully closed choke can lead to fuel flooding, while an open choke in cold weather can cause stalling.

- Check the fuel filter: If the engine stalls soon after starting, the fuel filter may be clogged, restricting the flow of gasoline. Replace the fuel filter if it’s dirty.

- Clean the carburetor: A dirty carburetor can lead to poor fuel delivery, causing the engine to stall. Cleaning the carburetor and adjusting the idle speed may resolve the issue.

- Inspect the spark plug: A weak or damaged spark plug may produce an inconsistent spark, causing the engine to stall. Replace it if it shows signs of wear or corrosion.

Engine Runs Rough or Misfires

If your engine runs, but you notice it running roughly, misfiring, or surging, it may be experiencing issues related to fuel delivery, ignition, or air intake.

Troubleshooting Steps:

- Check the fuel quality: Poor fuel can cause misfires or uneven engine operation. Drain the fuel and refill it with fresh gasoline if the problem persists.

- Inspect the carburetor: A carburetor that is incorrectly adjusted can cause the engine to run rich (too much fuel) or lean (too much air), leading to rough operation. Clean and adjust the carburetor.

- Examine the ignition system: Check for a faulty ignition coil or worn spark plug. These components are essential for maintaining a consistent spark.

- Ensure proper ventilation: A clogged air filter can restrict airflow, causing the engine to run poorly. Cleaning or replacing the air filter can improve engine performance.

Excessive Engine Smoking

Smoke coming from the engine can be alarming, and it often indicates that oil is being burned or that there is an imbalance in the fuel-to-air ratio.

Troubleshooting Steps:

- Check the oil level: If there is too much oil in the engine, it may leak into the combustion chamber, causing white or blue smoke. Drain the excess oil if necessary.

- Inspect the air filter: A clogged air filter can cause the engine to run rich, resulting in black smoke. Cleaning or replacing the filter can help resolve this issue.

- Check for worn piston rings or valves: If the engine continues to smoke, it may indicate that oil is seeping into the combustion chamber due to worn rings or valves. This requires more in-depth repairs, and you may need to consult a professional.

Engine Overheating

Overheating can cause serious damage to a small engine, so it’s important to address this issue promptly.

Troubleshooting Steps:

- Check the cooling system: Many small engines rely on air or oil cooling systems. Ensure that air vents or cooling fins are clean and free of debris.

- Check the oil level: Low oil can cause the engine to overheat. Ensure that there is sufficient oil in the engine, and change it if it’s dirty or degraded.

- Inspect the engine’s workload: Overloading the engine by using it for tasks it wasn’t designed for can cause overheating. Ensure you are using the engine within its designed limits.

Read more about overheating

Can a Water Pump Cause Overheating?

Can a Bad Radiator Cap Cause Overheating?

Can Radiator Fan Cause Overheating?

Can Radiator Stop Leak Cause Overheating?

Engine is Vibrating Excessively

Excessive vibration can indicate an imbalance or mechanical failure, which can lead to further damage if not addressed.

Troubleshooting Steps:

- Check for loose bolts: Loose components or engine mounting bolts can cause excessive vibration. Tighten any loose bolts you find.

- Inspect the blade (for mowers): If the blade is bent or unbalanced, it can cause the engine to vibrate. Replace or balance the blade if necessary.

- Check for damaged internal components: If the vibration persists, it may indicate a more serious internal problem, such as a bent crankshaft or damaged bearings. This issue may require professional attention.

Credit: www.yumpu.com

Preventive Maintenance Tips for Small Engines

Performing regular preventive maintenance on small engines is essential for ensuring their long-term performance and preventing costly repairs. By following a routine maintenance schedule, you can keep your lawnmower, chainsaw, generator, or other equipment running efficiently for years to come. Here are some key preventive maintenance tips for small engines:

- Use Fresh, Clean Fuel

- Always use clean, fresh fuel in your small engine. Gasoline that is more than a month old can go stale and may cause clogging or poor performance. If you plan to store the engine for an extended period, use a fuel stabilizer to prevent fuel breakdown.

- Change the Oil Regularly

- Regular oil changes are essential for small engines to keep internal components lubricated and prevent overheating. Check your engine’s manual for recommended oil change intervals.

- Clean or Replace the Air Filter

- A clean air filter ensures that your engine receives the proper air-to-fuel mixture, optimizing performance. Replace or clean the air filter according to the manufacturer’s recommendations.

- Inspect the Spark Plug

- Regularly inspect the spark plug for carbon buildup or wear. Replace it if necessary to maintain proper ignition.

- Perform Routine Cleaning

- Keep the exterior of the engine clean, and ensure that any cooling fins, vents, or air intakes are free of dirt and debris. This helps prevent overheating and improves overall efficiency.

Frequently Asked Questions

Here are some FAQs about small engine troubleshooting –

Why won’t my small engine start?

Common reasons for a small engine not starting include a lack of fuel, a dirty air filter, a faulty spark plug, or a clogged carburetor. Inspect these components and clean or replace them as necessary.

Why does my small engine sputter and die?

This could be caused by a dirty or improperly adjusted carburetor, stale fuel, or a clogged fuel filter. Check these components and clean or replace them if needed.

Why is my small engine smoking?

Smoking is often caused by burning oil or an imbalanced fuel-to-air mixture. Check the oil level, air filter, and carburetor to resolve the issue.

How can I prevent my small engine from overheating?

To prevent overheating, ensure that the engine is well-ventilated, the oil level is sufficient, and the air intake or cooling fins are clean. Avoid overloading the engine.

What maintenance should I perform regularly on my small engine?

Regular maintenance includes changing the oil, cleaning or replacing the air filter, inspecting the spark plug, and using fresh fuel. Cleaning the exterior and ensuring proper ventilation will also extend the engine’s lifespan.

Conclusion

Small engines are vital to many everyday machines, and understanding how to troubleshoot common problems can save time, money, and frustration. By recognizing the signs of potential issues, performing regular maintenance, and addressing minor problems early on, you can keep your small engine running smoothly for years to come. Whether it’s a lawnmower that won’t start or a generator that stalls, these troubleshooting steps will guide you through resolving many common small engine issues.