Timing belts are critical components in various mechanical and automotive systems, playing an essential role in synchronizing the rotation of engine parts. To fully grasp their functionality, it is vital to understand the nomenclature associated with timing belts.

In this article we will discuss the specific terminologies, classifications, and designations that define timing belts, offering insights into how these belts are categorized and identified in industry settings.

Contents

Key Components of Timing Belt Nomenclature

Timing belt nomenclature typically includes the following components:

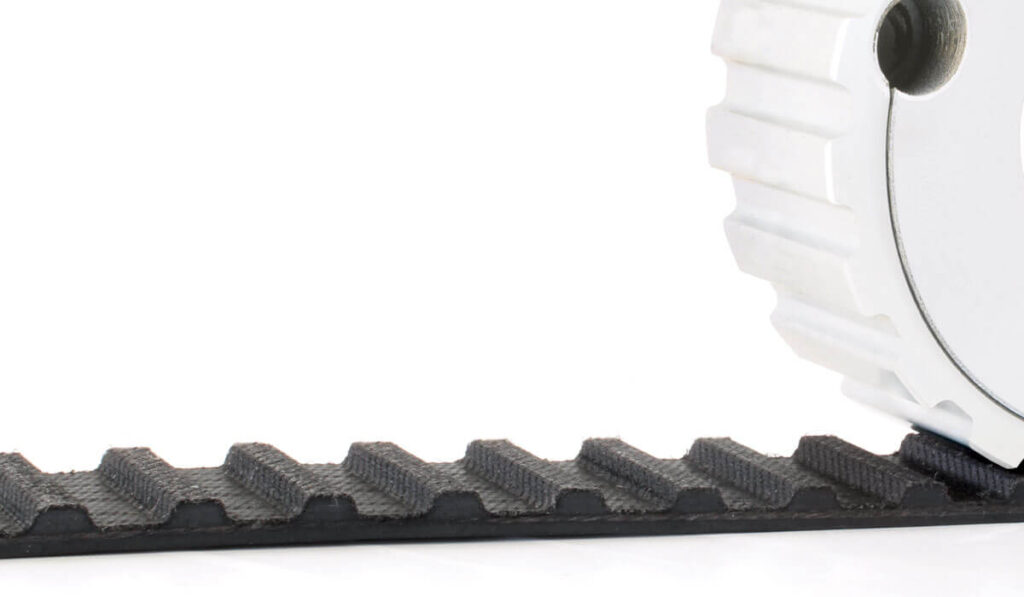

- Pitch (P): The distance between the center of one tooth to the center of the next tooth. This is a critical parameter in determining the compatibility of the belt with pulleys.

- Example: 5mm, 8mm, 14mm

- Belt Width (W): The overall width of the belt, which influences load capacity and torque transmission.

- Example: 9mm, 15mm, 25mm

- Length (L): The total circumference of the belt, often denoted in millimeters or inches.

- Example: 500mm, 1200mm

- Tooth Profile: The shape of the teeth on the belt, which can affect engagement and load distribution. Common profiles include trapezoidal, curvilinear, and modified curvilinear.

- Examples: MXL, XL, L, H (Imperial); HTD, GT2, GT3 (Metric)

- Material Composition: Timing belts can be made from rubber, polyurethane, and reinforced with materials like fiberglass, steel, or Kevlar for enhanced durability.

Common Timing Belt Nomenclature Systems

Here are some common timing belt nomenclature systems and how they are structured:

Imperial Timing Belt Designation

The imperial system often uses letter codes to indicate the tooth profile and size:

- MXL (Mini Extra Light): 0.080″ pitch, used for light-duty applications.

- XL (Extra Light): 0.200″ pitch, common in light machinery.

- L (Light): 0.375″ pitch, suitable for medium loads.

- H (Heavy): 0.500″ pitch, designed for heavier loads.

Metric Timing Belt Designation

Metric belts often use the High Torque Drive (HTD) and Gates PowerGrip GT systems:

- HTD Belts: Designed for high torque applications with curvilinear tooth profiles.

- Examples: 3M, 5M, 8M, 14M (denotes the pitch in millimeters)

- GT2, GT3 Belts: Gates proprietary belts with improved load distribution.

- Example: 5GT (5mm pitch)

Example of Belt Code Interpretation

A belt labeled as “8MGT-720-20” can be interpreted as:

- 8M: 8mm pitch (HTD profile)

- GT: Gates GT series

- 720: 720mm belt length

- 20: 20mm belt width

Material and Reinforcement Codes

Here’s a guide to common material and reinforcement codes and their meaning:

- Rubber (R): Common for general applications.

- Polyurethane (PU): Offers higher chemical resistance and durability.

- Fiberglass (FG): Provides flexibility and resistance to stretching.

- Steel (S): Offers high strength for heavy-duty applications.

- Kevlar (K): Known for lightweight and high tensile strength.

Selection Criteria Based on Nomenclature

When selecting a timing belt based on its nomenclature, it is crucial to consider the specifications encoded in the belt’s name. Here’s a guide to understanding and applying these criteria:

- Load Requirements: Heavier loads require belts with higher pitch and wider width.

- Speed and Torque: High-speed applications often need curvilinear tooth profiles to minimize slippage.

- Environmental Conditions: Polyurethane belts are suitable for chemical or high-temperature environments.

- Precision Needs: Fine-pitch belts like MXL are ideal for precise, small-scale operations.

Maintenance and Replacement Considerations

Knowing the nomenclature is critical when replacing or maintaining timing belts. Matching the correct pitch, tooth profile, and material ensures optimal performance and longevity. Always consult manufacturer specifications and guidelines for timing belt replacement.

Advantages of Proper Timing Belt Selection

Selecting the proper timing belt for your application offers numerous advantages, enhancing performance, reliability, and cost-efficiency. Here are the key benefits:

- Efficiency: Accurate matching reduces energy loss and improves system efficiency.

- Durability: Correct material and reinforcement selection prolongs belt life.

- Noise Reduction: Proper tooth profiles and tensioning minimize operational noise.

- Cost Savings: Reducing downtime and maintenance costs by choosing the correct belt.

Frequently Asked Questions

Here are some FAQs about timing belt nomenclature –

1. What is the difference between HTD and GT belts?

HTD belts have a curvilinear tooth profile designed for high torque, while GT belts are Gates’ proprietary design offering better load distribution and reduced backlash.

2. How do I identify the correct timing belt size?

Check the existing belt for printed codes or measure the pitch, width, and total length. Consult manufacturer specifications for exact replacement.

3. Why is pitch important in timing belts?

Pitch determines how the belt engages with the pulley, affecting synchronization and load transfer. Incorrect pitch can lead to slippage or mechanical failure.

4. Which materials are best for high-temperature environments?

Polyurethane belts reinforced with steel or Kevlar are ideal for high-temperature and chemically harsh environments.

5. How often should timing belts be replaced?

Replacement intervals depend on the application, but automotive timing belts are typically replaced every 60,000 to 100,000 miles. Always follow manufacturer recommendations.

Conclusion

Comprehending timing belt nomenclature is vital for selecting the right belt for specific applications. Whether for automotive engines, industrial machinery, or robotics, understanding pitch, width, tooth profile, material, and reinforcement options leads to more efficient and durable systems.

Proper knowledge of these specifications ensures enhanced performance, safety, and reliability in mechanical operations.