A bad crankshaft pulley often shows visible signs of wear, such as cracks, warping, or missing dampening material. You may also notice misalignment, leading to the pulley wobbling when the engine is running, or hear unusual noises like squealing or grinding. These issues can cause engine vibrations and accessory failures, indicating that the pulley needs to be inspected and replaced.

The crankshaft pulley, often referred to as the harmonic balancer, is a crucial component in your engine’s operation. It plays a vital role in ensuring that your engine runs smoothly by reducing vibrations and providing the necessary drive to various accessories like the alternator, power steering pump, and air conditioning compressor.

Over time, like all mechanical components, the crankshaft pulley can wear out or fail. Understanding what a bad crankshaft pulley looks like and how to identify the symptoms is essential for maintaining your vehicle’s health and avoiding costly repairs.

Contents

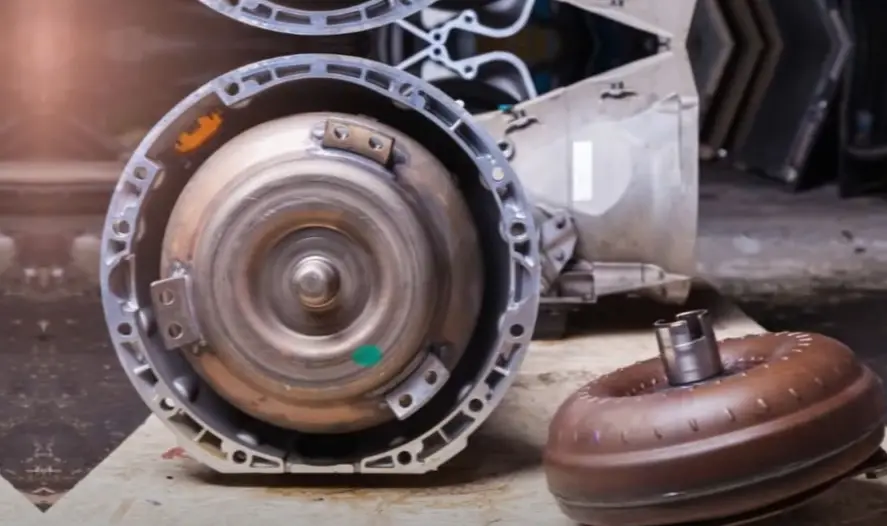

Crankshaft Pulley

Before diving into what a bad crankshaft pulley looks like, it’s important to understand its function. The crankshaft pulley is typically mounted on the front of the crankshaft and serves two primary purposes:

- Vibration Dampening: The crankshaft generates significant rotational force, which can cause vibrations. The crankshaft pulley helps dampen these vibrations to prevent engine damage and ensure smooth operation.

- Accessory Drive: The pulley is also responsible for driving the serpentine belt, which powers various engine accessories like the alternator, power steering pump, and air conditioning compressor.

Given these critical roles, a failing crankshaft pulley can lead to serious issues, both in terms of engine performance and the functioning of accessory systems.

Signs of a Bad Crankshaft Pulley

A bad crankshaft pulley can manifest in several ways. The following signs are indicative of a failing or damaged pulley:

- Visible Damage or Wear: The most obvious sign of a bad crankshaft pulley is visible damage. This may include cracks, chips, or warping on the pulley’s surface. If the rubber dampening material between the metal components of the pulley is worn, cracked, or missing, it indicates that the pulley is no longer effectively absorbing vibrations.

- Misalignment: A bad pulley may not sit flush against the crankshaft, leading to misalignment. This can cause the serpentine belt to slip off or wear unevenly. You may notice that the pulley wobbles or shifts when the engine is running, which is a clear sign of a problem.

- Unusual Noises: One of the early warning signs of a bad crankshaft pulley sound coming from the engine bay. These can range from a squealing or chirping sound to a more severe knocking or grinding noise. These sounds typically occur because the pulley is no longer aligned properly or the dampening material has deteriorated, leading to metal-on-metal contact.

- Vibration Issues: Since the crankshaft pulley’s primary function is to dampen vibrations, a failing pulley can lead to noticeable vibrations in the engine. These vibrations may be felt throughout the vehicle, especially at idle or during acceleration. Over time, excessive vibrations can cause further damage to the engine and other components.

- Accessory Failure: If the crankshaft pulley is no longer driving the serpentine belt effectively, you may experience failures in the accessories it powers. This could include issues with the alternator (leading to a dead battery), power steering problems, or the air conditioning not functioning correctly.

- Check Engine Light: In some cases, a failing crankshaft pulley can trigger the check engine light. This typically happens if the engine’s timing is affected, leading to misfires or other performance issues.

Causes of Crankshaft Pulley Failure

Understanding what causes a crankshaft pulley to fail can help in preventing issues and prolonging the life of this critical component. The following are common causes of crankshaft pulley failure:

- Age and Wear: Like any component, the crankshaft pulley is subject to wear and tear over time. The rubber dampening material can degrade, and the metal components can corrode or weaken with age.

- Exposure to Extreme Conditions: The pulley is exposed to harsh conditions under the hood, including extreme temperatures, oil, and debris. These factors can accelerate wear and lead to premature failure.

- Improper Installation: If the pulley was not installed correctly, it could lead to misalignment and uneven wear. This is especially common after engine repairs or replacements where the pulley needs to be removed and reinstalled.

- Defective Parts: In some cases, the pulley may fail due to a manufacturing defect. This is less common but can occur, especially in aftermarket parts that may not meet the same quality standards as OEM components.

- Engine Modifications: High-performance engines or engines that have been modified for increased power output can place additional strain on the crankshaft pulley, leading to premature failure.

How to Diagnosis Crankshaft Pulley Failing

If you suspect that your crankshaft pulley is failing, it’s important to have it inspected and diagnosed by a professional mechanic. Here’s what typically happens during an inspection:

- Visual Inspection: The mechanic will first perform a visual inspection to check for any obvious signs of damage, such as cracks, wear, or misalignment.

- Noise Diagnosis: If unusual noises are present, the mechanic may use a stethoscope or other diagnostic tools to pinpoint the source of the noise and confirm whether it’s coming from the crankshaft pulley.

- Vibration Analysis: The mechanic may also check for excessive vibrations in the engine. This can be done visually or with specialized equipment that measures the level of vibration.

- Belt Condition: The condition of the serpentine belt will also be checked, as a bad pulley can cause the belt to wear unevenly or slip off.

- Pulley Removal: In some cases, the pulley may need to be removed for a more thorough inspection. This allows the mechanic to check the condition of the dampening material and the fit of the pulley on the crankshaft.

How to Repair and Replace Crankshaft Pulley

If the crankshaft pulley is found to be faulty, it will need to be replaced. This is not a repairable component, as any damage to the pulley compromises its ability to function properly. The replacement process typically involves the following steps:

- Removing the Serpentine Belt: The serpentine belt must be removed to access the crankshaft pulley.

- Removing the Old Pulley: Remove Crankshaft Pulley. This may require a specialized pulley puller tool.

- Installing the New Pulley: The new pulley is installed, ensuring that it is properly aligned and seated on the crankshaft.

- Reinstalling the Serpentine Belt: The serpentine belt is then reinstalled, and its tension is checked to ensure proper operation.

- Final Inspection: After installation, the mechanic will perform a final inspection to ensure that the pulley is functioning correctly and that there are no abnormal noises or vibrations.

Frequently Asked Questions

Here are some FAQs about the bad crankshaft pulley –

1. How long does a crankshaft pulley last?

A crankshaft pulley can last anywhere from 100,000 to 150,000 miles, depending on driving conditions, maintenance, and the quality of the pulley.

2. Can I drive with a bad crankshaft pulley?

Driving with a bad crankshaft pulley is not recommended. It can lead to engine damage, accessory failure, and even complete engine shutdown.

3. What does it cost to replace a crankshaft pulley?

The cost to replace a crankshaft pulley can range from $200 to $500, depending on the make and model of your vehicle and labor costs.

4. How can I prevent crankshaft pulley failure?

Regular inspections, avoiding exposure to extreme conditions, and using high-quality parts can help prevent crankshaft pulley failure.

5. Can a bad crankshaft pulley cause engine misfires?

Yes, a bad crankshaft pulley can cause engine misfires if it affects the timing of the engine. This can trigger the check engine light and lead to performance issues.

Conclusion

A bad crankshaft pulley is a serious issue that can lead to various engine and accessory problems. Recognizing the signs of a failing pulley, such as visible damage, unusual noises, vibrations, and accessory failures, is crucial for timely repairs. Regular inspections and maintenance can help prevent pulley failure and ensure that your engine runs smoothly. If you suspect your crankshaft pulley is bad, it’s important to have it inspected and replaced by a professional mechanic to avoid further damage to your vehicle.