Magnesium valve covers are used primarily for their lightweight nature, which helps reduce overall vehicle weight, improving fuel efficiency and performance. They also offer good thermal conductivity, which aids in heat dissipation, and have vibration-damping properties that reduce engine noise. While magnesium is more expensive and requires special manufacturing processes, its benefits are valuable for high-performance and luxury vehicles.

When it comes to automotive engineering, material choice is a critical factor that significantly affects performance, efficiency, and durability. One such material that has been gaining traction for specific applications is magnesium. Known for its unique properties, magnesium is particularly useful in constructing various car components, including the valve cover.

Contents

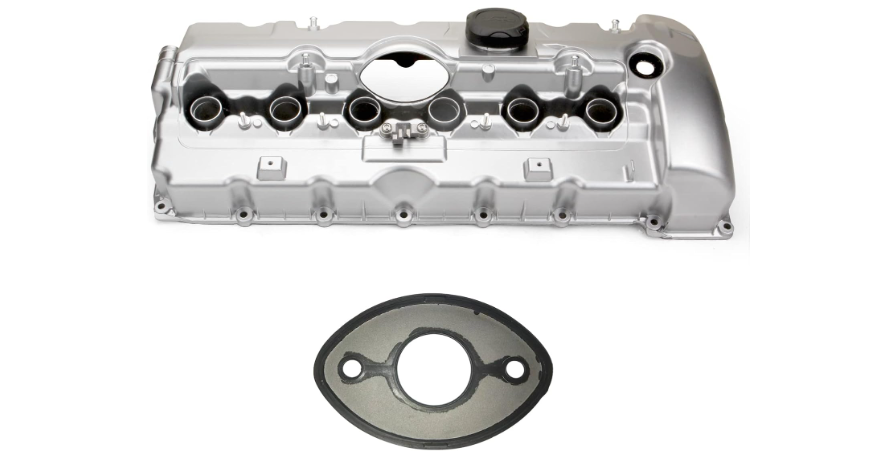

Why Make a Valve Cover Out of Magnesium?

Magnesium is the lightest of all structural metals, weighing about one-third less than aluminum. This lightweight characteristic makes magnesium an attractive option for automotive applications, especially when weight reduction is a priority. But the benefits of magnesium go beyond its lightweight nature:

- Weight Reduction and Performance

Magnesium’s density is about 1.74 g/cm³, significantly lower than that of aluminum (2.7 g/cm³) and steel (7.85 g/cm³). This low density contributes to substantial weight savings, which is crucial in high-performance and racing vehicles where every gram matters. A lighter valve cover means reduced overall vehicle weight, leading to improved fuel efficiency, better handling, and enhanced acceleration. - High Strength-to-Weight Ratio

Despite being lighter, magnesium exhibits an excellent strength-to-weight ratio. This property ensures that a magnesium valve cover can withstand the mechanical stresses and thermal cycles experienced by the engine. While magnesium is not as strong as steel, when properly alloyed, it can offer comparable performance to aluminum while maintaining a much lower weight. - Good Thermal Conductivity

Magnesium has superior thermal conductivity compared to many other metals used in automotive components. This property enables better heat dissipation from the engine, helping to maintain optimal operating temperatures and potentially prolonging the lifespan of the engine components. Efficient heat dissipation is particularly crucial in high-performance engines that generate a lot of heat. - Vibration Damping and Noise Reduction

Magnesium possesses intrinsic damping properties that help reduce vibrations and noise generated by the engine. This can contribute to a quieter and smoother running vehicle, enhancing overall driving comfort. For instance, in performance or luxury vehicles, minimizing noise, vibration, and harshness (NVH) is a critical aspect of design, and magnesium components can play a significant role in achieving these goals. - Corrosion Resistance

With the addition of specific alloys and surface treatments, magnesium can offer good corrosion resistance, comparable to or even better than aluminum. Magnesium alloys often undergo treatments such as anodizing or coating to enhance their resistance to environmental factors like moisture, road salt, and chemicals. A magnesium valve cover, therefore, can have a long service life even in harsh conditions. - Recyclability and Environmental Impact

Magnesium is a highly recyclable metal, with a lower carbon footprint during production compared to other metals like steel. Using magnesium in automotive applications aligns with the industry’s push toward sustainable materials and practices. Additionally, recycling magnesium consumes less energy than producing it from ore, making it an environmentally friendly choice.

Applications of Magnesium Valve Covers

Due to the benefits outlined above, magnesium valve covers are commonly used in:

- High-Performance Sports Cars: Magnesium’s lightweight and high strength make it ideal for sports cars where every bit of weight reduction contributes to better performance. Cars like the Porsche 911 GT3 and various Ferraris have used magnesium components, including valve covers, to optimize performance.

- Luxury Vehicles: The noise reduction and vibration-damping qualities of magnesium can enhance the driving experience in luxury cars. Brands like BMW and Mercedes-Benz have experimented with magnesium valve covers to minimize engine noise and vibrations.

- Aviation and Motorsports: In racing cars and airplanes, magnesium valve covers are often employed for their lightweight properties, contributing to overall weight reduction and improved performance metrics such as acceleration and fuel economy.

Challenges of Using Magnesium for Valve Covers

While magnesium offers many advantages, there are some challenges and limitations associated with its use:

- Cost

Magnesium is generally more expensive than aluminum or steel. The cost of raw materials, along with the need for specialized manufacturing processes and treatments, can make magnesium valve covers a pricier option. However, for applications where performance outweighs cost concerns, such as motorsports or luxury vehicles, the benefits often justify the investment. - Manufacturing Challenges

Magnesium requires careful handling during manufacturing due to its flammability in powder or molten form. Specialized casting and machining techniques are necessary to prevent ignition, which can increase production costs. Additionally, magnesium can be more challenging to work with than aluminum or steel, requiring manufacturers to adapt their processes and tooling. - Lower Ductility

Magnesium is less ductile than aluminum, which means it is more prone to cracking under certain stress conditions. Engineers must take this into account during the design process to ensure that magnesium components can withstand the operational loads without failure. - Surface Treatment Requirements

To enhance corrosion resistance and durability, magnesium components often require additional surface treatments, such as anodizing or coating. These treatments can add complexity and cost to the production process. Without proper treatment, magnesium can corrode quickly, particularly in environments with high moisture or salt exposure. - Limited Availability and Supply Chain Issues

Magnesium is less abundant than other metals like aluminum, and its production is concentrated in certain countries, leading to potential supply chain vulnerabilities. Fluctuations in availability and pricing can pose challenges for manufacturers relying on a steady supply of magnesium.

Frequently Asked Questions

Here are some FAQs about the Magnesium valve covers –

- Why are magnesium valve covers used in performance cars?

Magnesium valve covers are used in performance cars due to their lightweight properties, which contribute to weight reduction, better handling, improved acceleration, and increased fuel efficiency. - Are magnesium valve covers durable?

Yes, magnesium valve covers are durable when appropriately treated. They offer good corrosion resistance and can withstand the mechanical stresses and thermal cycles of engine operation, particularly when alloyed and coated correctly. - What are the challenges of using magnesium for valve covers?

Challenges include higher costs, manufacturing difficulties due to flammability and lower ductility, and the need for specialized surface treatments to prevent corrosion. - How do magnesium valve covers help with noise reduction?

Magnesium has intrinsic damping properties that help reduce engine vibrations and noise, contributing to a quieter and smoother vehicle operation. - Is magnesium environmentally friendly?

Yes, magnesium is considered environmentally friendly due to its recyclability and lower carbon footprint compared to other metals like steel. Recycling magnesium requires less energy than producing it from raw ore.

Related Article

Can Valve Cover Gasket Have Low Oil Pressure

Can Valve Cover Gasket Cause Oil in Coolant

Why Do Valve Cover Gaskets Go Bad?

What Does a Valve Cover Gasket Look Like?

Conclusion

Magnesium valve covers offer a range of benefits that make them an attractive choice for high-performance, luxury, and specialty vehicles. With their lightweight nature, excellent thermal conductivity, vibration damping properties, and recyclability.

As the automotive industry continues to evolve, with a growing emphasis on performance, efficiency, and sustainability, magnesium may play an increasingly important role in the future of vehicle design. For now, magnesium valve covers remain a specialized choice, reserved for applications where their unique properties offer a clear advantage.