Yes, an incorrect pinion angle can cause vibrations in a vehicle’s drivetrain. When the pinion angle is misaligned, it can lead to uneven rotation of the driveshaft and increased wear on the U-joints, resulting in noticeable vibrations, especially at certain speeds. Correcting the pinion angle is crucial to ensure smooth operation and prevent potential damage.

Understanding the dynamics of a vehicle’s drivetrain is crucial for maintaining optimal performance and comfort, especially when it comes to managing vibrations. One critical aspect that often goes overlooked is the pinion angle. Improper pinion angle can be a major source of vibration issues, leading to discomfort and potential damage to your vehicle.

Contents

What is Pinion Angle?

Before diving into how pinion angle can cause vibrations, it’s essential to understand what pinion angle is and its role in a vehicle’s drivetrain.

- Pinion Angle Defined: The pinion angle refers to the angle between the pinion shaft (which drives the differential) and the driveshaft. In a typical rear-wheel-drive vehicle, the driveshaft connects the transmission to the differential. The pinion angle is crucial because it affects how the driveshaft and the universal joints (U-joints) operate as the vehicle moves.

- Universal Joint Operation: Universal joints are designed to accommodate changes in angle between the driveshaft and the pinion shaft as the suspension moves. However, for the U-joints to function smoothly, the pinion angle must be set correctly to minimize vibration and wear.

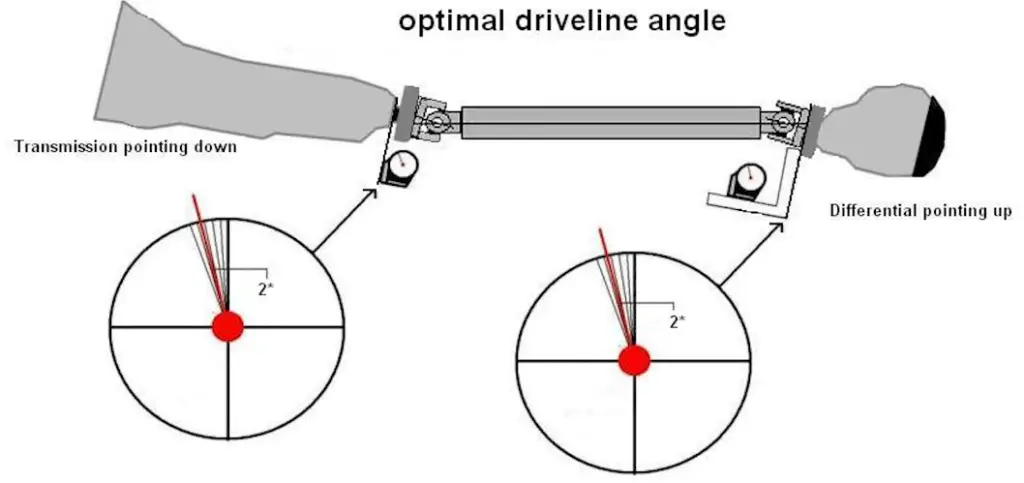

- Ideal Pinion Angle: The ideal pinion angle varies depending on the vehicle and its specific setup, but a general rule of thumb is that the angle of the pinion and the angle of the transmission output shaft should be equal and opposite. This alignment allows the U-joints to operate within their designed parameters, preventing unnecessary strain and vibration.

How Pinion Angle Causes Vibration

An incorrect pinion angle can disrupt the smooth operation of the drivetrain, leading to vibrations that can range from mildly annoying to severely damaging. Here’s how improper pinion angle contributes to vibration:

- U-Joint Phasing Issues: When the pinion angle is incorrect, the U-joints at either end of the driveshaft are forced to operate at different angles. This mismatch, known as out-of-phase U-joints, leads to uneven rotation of the driveshaft, causing vibrations. These vibrations can be felt throughout the vehicle, particularly at certain speeds when the angles exacerbate the imbalance.

- Increased U-Joint Wear: U-joints are designed to handle certain angles of operation. If the pinion angle is too steep or too shallow, it can cause excessive wear on the U-joints. This wear leads to looseness and play in the drivetrain, which in turn causes vibration.

- Driveshaft Harmonics: The driveshaft itself can resonate at certain frequencies, depending on its length, material, and speed of rotation. An incorrect pinion angle can push the driveshaft into a harmonic range that causes it to vibrate. These vibrations can be particularly severe at specific speeds, leading to a phenomenon known as “driveline shudder.”

- Axle Wrap and Pinion Angle Changes: In vehicles with significant torque, such as those with powerful engines or heavy-duty applications, axle wrap can occur. Axle wrap is when the axle housing twists under load, causing a temporary change in pinion angle. If the suspension is not designed to handle this twist, the changing pinion angle can cause vibrations during acceleration or under load.

- Impact on Other Components: An incorrect pinion angle can also place additional stress on other drivetrain components, such as the transmission, differential, and even the engine mounts. This extra stress can lead to accelerated wear and further vibrations as these components start to fail.

How to Identify Pinion Angle Vibrations

Vibrations can originate from various sources in a vehicle, so it’s important to accurately diagnose whether the pinion angle is the root cause. Here are some signs that your pinion angle might be causing vibration:

- Vibration at Specific Speeds: If you notice vibrations only at certain speeds, particularly during acceleration or deceleration, this could be a sign of a pinion angle issue. Vibrations that occur at highway speeds but disappear at lower speeds are often related to driveline angles.

- Changes After Suspension Modifications: If you’ve recently installed a lift kit, lowered your vehicle, or made other suspension modifications, and you begin to experience vibrations, the pinion angle may have been altered in the process. These changes can affect the driveshaft angle and lead to vibration issues.

- Driveline Shudder: A noticeable shudder in the vehicle, particularly when starting from a stop or during heavy acceleration, is a classic symptom of an incorrect pinion angle. This shudder is often due to the driveshaft operating at an improper angle, causing U-joints to bind and release unevenly.

- Visible Misalignment: In some cases, you can visually inspect the pinion angle by looking at the driveshaft and differential alignment. If the angles between the transmission output shaft, driveshaft, and pinion are visibly out of alignment, this could be the cause of your vibrations.

- Premature U-Joint Failure: If you find yourself replacing U-joints more frequently than expected, it’s worth checking the pinion angle. An incorrect angle can accelerate U-joint wear, leading to premature failure and increased vibrations.

Correcting Pinion Angle to Eliminate Vibrations

Once you’ve identified that an incorrect pinion angle is causing vibrations, the next step is to correct it. Here’s how you can go about adjusting the pinion angle:

- Measure the Current Pinion Angle: Use an angle finder or an inclinometer to measure the current pinion angle. You’ll need to measure the angle of the transmission output shaft and the angle of the pinion shaft. Compare these angles to determine if they are equal and opposite, as they should be.

- Adjusting the Pinion Angle: Depending on the type of suspension your vehicle has, there are different ways to adjust the pinion angle:

- Leaf Spring Suspension: On vehicles with leaf spring suspensions, you can use angled shims between the leaf springs and the axle to adjust the pinion angle. These shims tilt the axle housing, changing the angle of the pinion shaft.

- Four-Link or Trailing Arm Suspension: Vehicles with four-link or trailing arm suspensions allow for more precise adjustments by altering the length of the control arms. Adjusting the length of the upper or lower control arms will tilt the differential, changing the pinion angle.

- Coil Spring Suspension: Similar to the four-link suspension, coil spring setups can often be adjusted by changing the control arms’ length or using adjustable arms specifically designed for pinion angle correction.

- Rechecking the Angle: After making adjustments, re-measure the pinion angle to ensure it is within the recommended range. The exact angle can vary, but typically, the pinion angle should be within 1-3 degrees of the transmission output shaft angle.

- Test Drive: After adjusting the pinion angle, take the vehicle for a test drive. Pay attention to any changes in vibration, especially at the speeds where it was most noticeable before. If the vibration persists, you may need to fine-tune the angle further.

- Consider Professional Help: If you’re unsure about how to measure pinion angle, or if the vibrations persist despite your best efforts, it may be worth consulting a professional. An experienced mechanic or driveline specialist can accurately diagnose and correct the issue.

How to Prevent Pinion Angle Vibrations

To avoid pinion angle-related vibrations in the future, it’s essential to follow some best practices:

- Maintain Proper Suspension Geometry: When modifying your vehicle’s suspension, always consider how changes will affect the pinion angle. Lift kits, lowering kits, and other suspension modifications can all impact the drivetrain geometry, so make sure to compensate for these changes as needed.

- Regular Inspections: Periodically check your vehicle’s pinion angle, especially after making any modifications or if you notice any new vibrations. Regular inspections can help catch issues before they become severe.

- Use Quality Components: When adjusting the pinion angle or modifying the suspension, use high-quality components such as adjustable control arms, shims, and U-joints. Quality parts are less likely to wear out prematurely and will help maintain the correct angles.

- Understand Your Vehicle’s Specifications: Every vehicle has specific guidelines for pinion angles, especially under load. Refer to your vehicle’s manual or consult with a specialist to understand the recommended angles for your specific make and model.

- Monitor for Changes: Keep an eye on your vehicle’s handling and listen for any new noises or vibrations. Changes in the way your vehicle drives can be an early indicator of pinion angle issues.

Conclusion

Pinion angle is a critical factor in ensuring a smooth and vibration-free ride in any vehicle. An incorrect pinion angle can lead to significant driveline vibrations, causing discomfort and potential damage to your vehicle. By understanding how pinion angle affects the drivetrain, how to identify issues, and how to correct them, you can maintain optimal performance and extend the lifespan of your vehicle’s components.