Yes, fully counterweighted crankshafts are durable due to their superior balance and reduced vibration, which minimizes wear and stress on engine components. Their design enhances the longevity of the crankshaft, making them ideal for high-performance and heavy-duty applications. The use of high-quality materials and precision manufacturing further contributes to their durability.

A crankshaft is a critical component in an internal combustion engine, responsible for converting the linear motion of the pistons into rotational motion that drives the vehicle. The design and construction of a crankshaft significantly impact the engine’s performance, efficiency, and durability.

One of the key design elements in modern crankshafts is counterweighting. Fully counterweighted crankshafts, in particular, have gained attention for their potential benefits in performance and durability. But are they truly durable, and what advantages do they offer?

Contents

Counterweighting in Crankshafts

Before diving into the durability aspect, it’s essential to understand what counterweighting is and why it’s necessary. Counterweights are added to the crankshaft to balance the forces generated by the rotating and reciprocating components within the engine. These forces include the weight of the pistons, connecting rods, and the crankshaft itself.

Without proper counterweighting, these forces can cause excessive vibration and stress on the engine’s components, leading to premature wear and potential failure. Counterweighting helps to reduce these forces, improving engine smoothness and longevity.

Fully Counterweighted Crankshafts: What Are They?

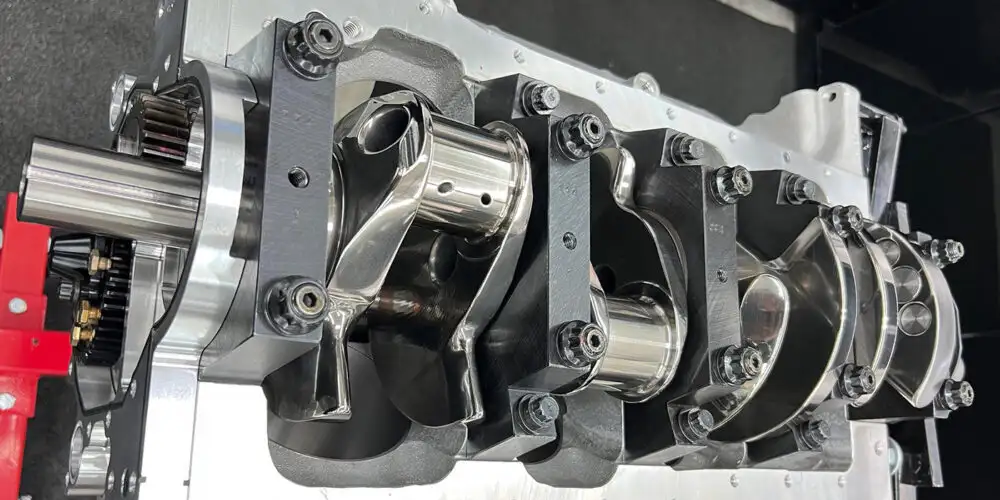

A fully counterweighted crankshaft is designed with counterweights on every crank throw. This design contrasts with partially counterweighted crankshafts, where only some of the crank throws have counterweights. Fully counterweighted designs are typically found in high-performance and heavy-duty engines, where the demands on the crankshaft are higher.

Advantages of Fully Counterweighted Crankshafts

Fully counterweighted crankshafts offer several advantages that enhance engine performance and longevity:

- Improved Balance and Reduced Vibration: Fully counterweighted crankshafts offer superior balance compared to their partially counterweighted counterparts. This improved balance reduces the engine’s vibration levels, leading to a smoother operation. Lower vibration not only enhances the driving experience but also reduces stress on other engine components, contributing to overall durability.

- Enhanced Durability: The reduced vibration and balanced forces in fully counterweighted crankshafts minimize the wear and tear on the engine’s internal components. This design reduces the risk of fatigue failure in the crankshaft itself, leading to a longer lifespan. The even distribution of forces also helps prevent crankshaft flexing, which can cause microfractures and eventual failure.

- Higher RPM Capability: Engines with fully counterweighted crankshafts can typically handle higher RPMs (revolutions per minute) without compromising stability. This capability is particularly beneficial in performance applications where engines are pushed to their limits. The reduced stress on the crankshaft at high RPMs ensures that the engine can operate reliably under demanding conditions.

- Increased Engine Efficiency: Fully counterweighted crankshafts contribute to improved engine efficiency. The balanced rotational forces reduce parasitic losses within the engine, allowing it to operate more efficiently. This efficiency translates to better fuel economy and potentially higher power output, depending on the engine’s design.

- Versatility in Engine Design: The durability and performance benefits of fully counterweighted crankshafts make them a versatile choice for various engine types, from high-performance sports cars to heavy-duty trucks. Their ability to withstand higher stresses makes them suitable for applications where reliability and longevity are critical.

Durability of Fully Counterweighted Crankshafts

The durability of a fully counterweighted crankshaft is influenced by several factors, including the material used, manufacturing process, and the specific engine application. However, in general, fully counterweighted crankshafts are known for their durability due to the following reasons:

- Material Strength: High-quality crankshafts are typically made from forged steel, a material known for its strength and durability. Forged steel crankshafts, particularly those with full counterweighting, can withstand the high stresses encountered in demanding engine applications. The forging process aligns the grain structure of the steel, enhancing its strength and resistance to fatigue.

- Reduced Stress Concentration: Fully counterweighted crankshafts distribute the forces more evenly across the crankshaft, reducing stress concentrations that can lead to cracks and failures. This even distribution of forces helps prevent localized stress points, enhancing the overall durability of the crankshaft.

- Improved Heat Dissipation: The design of fully counterweighted crankshafts allows for better heat dissipation, which is crucial in high-performance engines that generate significant amounts of heat. Efficient heat dissipation helps prevent thermal stress and the potential for heat-related failures, contributing to the crankshaft’s longevity.

- Precision Manufacturing: The manufacturing process of fully counterweighted crankshafts involves precision machining and balancing. This precision ensures that the crankshaft operates smoothly and reliably, with minimal wear over time. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, further enhance the durability of these crankshafts.

Applications of Fully Counterweighted Crankshafts

Fully counterweighted crankshafts are commonly used in high-performance engines, racing applications, and heavy-duty engines where durability and reliability are paramount. These applications include:

- High-Performance Sports Cars: In sports cars, fully counterweighted crankshafts provide the necessary durability to handle high RPMs and the increased power output. The reduced vibration and improved balance enhance both performance and longevity.

- Heavy-Duty Trucks: Heavy-duty trucks require crankshafts that can withstand the rigors of hauling heavy loads and operating under extreme conditions. Fully counterweighted crankshafts offer the durability needed to ensure reliable operation over long distances and extended periods.

- Racing Engines: In racing engines, where every ounce of performance is critical, fully counterweighted crankshafts provide the stability and durability required to handle high speeds and intense stress. These crankshafts are often used in engines that operate at the upper limits of their RPM range.

- Aviation Engines: Aviation engines, which demand the highest levels of reliability, often use fully counterweighted crankshafts to ensure smooth and dependable operation during flight.

Related Article

Crankshaft Journal Overlap

Are Crankshaft Bolts Reverse Thread?

What Does a Bad Crankshaft Pulley Look Like?

How to Remove Crankshaft Pulley Without Tool

Frequently Asked Questions

Here are some FAQs about the fully counterweighted crankshafts –

1. What is the main difference between fully and partially counterweighted crankshafts?

Fully counterweighted crankshafts have counterweights on every crank throw, providing better balance and reduced vibration, whereas partially counterweighted crankshafts only have counterweights on some throws.

2. Are fully counterweighted crankshafts more expensive?

Yes, fully counterweighted crankshafts are typically more expensive due to the additional material, complexity in design, and precision manufacturing required.

3. Can I use a fully counterweighted crankshaft in any engine?

Fully counterweighted crankshafts are best suited for high-performance or heavy-duty engines. They may not be necessary for standard passenger vehicles unless specific performance or durability needs are present.

4. How do fully counterweighted crankshafts affect engine performance?

They improve engine performance by reducing vibration, allowing for higher RPM capability, and enhancing overall engine efficiency.

5. Do fully counterweighted crankshafts require special maintenance?

No special maintenance is required beyond regular engine maintenance, but ensuring proper installation and balancing is crucial for optimal performance and longevity.

Conclusion

Fully counterweighted crankshafts are durable and reliable components that offer significant advantages in terms of engine balance, reduced vibration, and overall longevity. Their design makes them ideal for high-performance and heavy-duty applications where durability is essential. While the specific durability of a fully counterweighted crankshaft depends on factors like material and manufacturing quality, they are generally considered to be a robust choice for demanding engine applications.