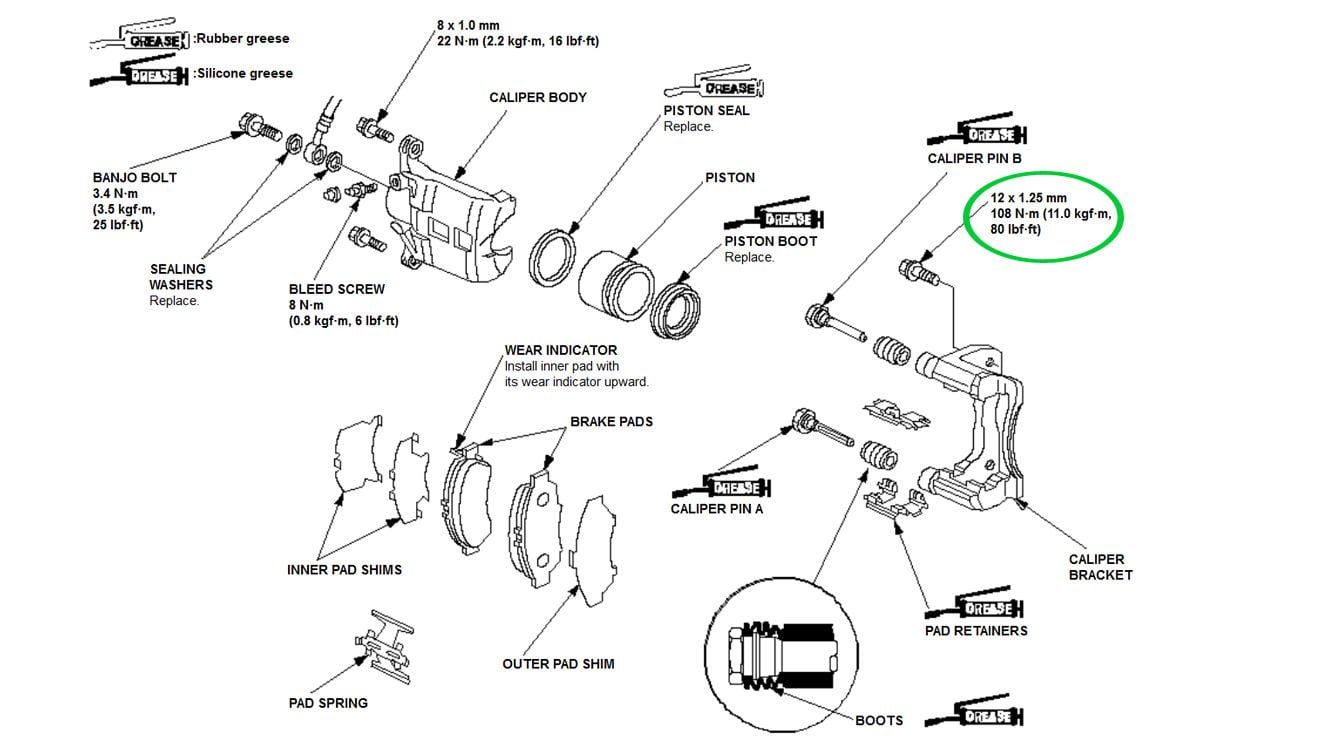

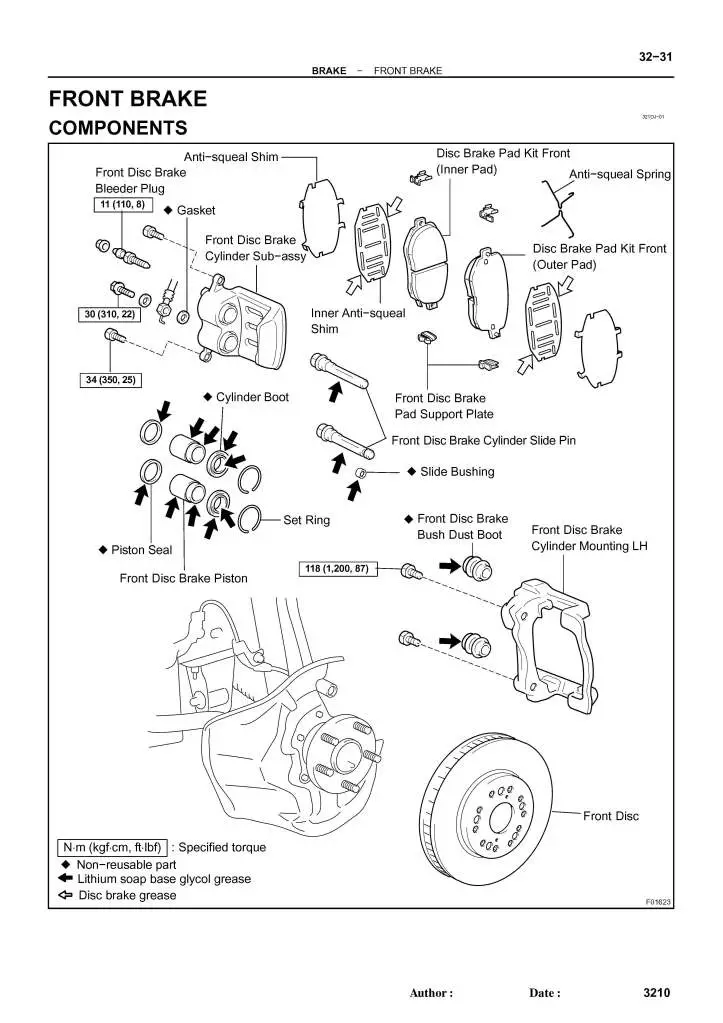

The brake caliper torque specs for your vehicle can be found in the manufacturer’s service manual. It’s important to use the specified torque to ensure proper brake system function and safety.

Ensuring the correct torque specifications for your brake calipers is crucial for maintaining the safety and performance of your vehicle. Proper torque helps prevent issues such as uneven brake pad wear, brake noise, and brake system failure. Additionally, using the manufacturer’s specified torque values helps maintain the structural integrity of the brake components, ensuring they function optimally under braking forces.

By following the recommended torque specs, you can help prolong the lifespan of your brake system and ensure reliable braking performance.

Credit: www.fitfreak.net

Contents

Why Are Brake Caliper Torque Specs Important?

Properly torqued brake calipers are essential for the following reasons:

1. Safety

Loose caliper bolts can cause the caliper to detach from its mount, which can lead to brake failure while driving. Over-torqued bolts can strip threads, leading to a weaker connection or difficulty removing the bolts in the future. Both under- and over-torquing present serious safety hazards.

2. Brake Performance

When calipers are not properly torqued, they can misalign with the brake rotors. This can lead to uneven wear on the brake pads, decreased braking efficiency, and increased stopping distances.

3. Preventing Damage

Over-torquing the caliper bolts can cause thread damage in the caliper mounting holes, leading to costly repairs. Under-torquing can cause excessive vibration or allow the caliper to move, leading to potential rotor and caliper damage.

4. Longevity

Correctly torquing the caliper bolts helps maintain the integrity of the braking system and extends the lifespan of brake components. Proper torque also prevents the need for re-tightening the bolts after installation.

How to Find the Correct Brake Caliper Torque Specs

Finding the correct brake caliper torque specifications is essential to ensure the safe and proper installation of brake components. Incorrect torque can lead to brake failure or damage to the brake system. Here’s how you can find the right brake caliper torque specs for your vehicle:

1. Owner’s Manual

The most reliable source for your car’s brake caliper torque specifications is the vehicle’s owner’s manual. It contains specific information for your vehicle, including torque specs for critical components like the calipers.

2. Service or Repair Manual

If the owner’s manual doesn’t provide enough detail, a service or repair manual for your specific make and model will have more detailed information, including torque specs for all brake-related components. These manuals are available through manufacturers, auto parts stores, or online.

3. Online Resources

Many online automotive forums, parts websites, and databases provide torque specifications for various vehicle models. Make sure to use reputable sources, such as manufacturer websites or trusted automotive repair databases like AllData or Chilton.

4. Torque Wrench

Once you have the correct torque specification, you’ll need a torque wrench to ensure that the caliper bolts are tightened to the specified value. A torque wrench measures the amount of force applied to the bolt, helping you avoid over- or under-tightening.

General Torque Specs for Common Vehicle Types

While specific torque values will vary depending on the vehicle’s make and model, here are some general guidelines for brake caliper torque specs by vehicle type:

1. Passenger Cars

For most standard passenger vehicles, brake caliper bolts are typically torqued between 20 and 40 lb-ft for the caliper slide pins and 70 to 90 lb-ft for the caliper bracket bolts. Always consult the vehicle’s manual for exact specifications.

2. SUVs and Light Trucks

Larger vehicles like SUVs and light-duty trucks often require higher torque settings due to their increased weight and brake system size. Caliper bracket bolts on these vehicles can be torqued between 90 and 120 lb-ft, while slide pins are usually tightened to between 25 and 45 lb-ft.

3. Heavy-Duty Trucks

For heavy-duty trucks, especially those with larger, heavy-duty brake systems, caliper torque specs can range from 100 to 150 lb-ft or more for the bracket bolts and between 40 and 60 lb-ft for the slide pins.

4. Performance Vehicles

High-performance cars often have specific torque requirements due to the use of specialized brake components like Brembo or Wilwood calipers. In these cases, the manufacturer’s torque specifications should be followed precisely, as high-performance brake systems can have very different torque requirements from standard systems.

5. Motorcycles

For motorcycles, brake caliper torque specs are usually lower than for cars and trucks. Front caliper bolts are typically torqued between 18 and 30 lb-ft, while rear caliper bolts may range from 15 to 25 lb-ft. It is always advisable to refer to the motorcycle’s service manual for accurate specs.

How to Properly Torque Brake Caliper Bolts

Properly torquing brake caliper bolts is crucial for the safety and longevity of your braking system. If the bolts are under-tightened, they may loosen over time, leading to brake failure. Over-tightening them can strip threads or damage the bolts. Here’s a step-by-step guide on how to properly torque brake caliper bolts:

1. Gather the Right Tools

To properly torque your brake caliper bolts, you will need:

- A torque wrench (calibrated for the correct range)

- A socket set to match the bolt sizes on your vehicle

- Anti-seize compound or thread locker (if recommended by the manufacturer)

2. Prepare the Vehicle

Ensure the car is safely elevated on jack stands and the wheel is removed, giving you clear access to the brake caliper and bolts.

3. Clean the Threads

Before installing or tightening the caliper bolts, clean the threads with a wire brush or compressed air to remove debris. This ensures proper torque application.

4. Apply Thread Locker (if applicable)

Some vehicles or manufacturers recommend applying a small amount of thread locker to the caliper bolts to prevent them from loosening over time. However, be cautious about using anti-seize on bolts unless specified, as it can affect torque accuracy.

5. Tighten to Spec

Using your torque wrench, slowly tighten the caliper bolts to the specified torque setting. Always follow the manufacturer’s recommended torque pattern, if provided, to ensure even pressure across the caliper.

Common Mistakes When Torquing Brake Caliper Bolts

When torquing brake caliper bolts, even small mistakes can lead to serious issues, including improper brake performance or damage to the braking system. Here are some common mistakes people make when torquing brake caliper bolts and how to avoid them:

1. Not Using a Torque Wrench: Attempting to guess the torque value or using a standard ratchet without a torque wrench can lead to improper tightening. A torque wrench is the only reliable way to apply the correct amount of force.

2. Over-Tightening: It’s easy to assume that tighter is better, but over-torquing can damage the threads on the caliper mounting holes or bolts, potentially compromising the brake system.

3. Ignoring Manufacturer Recommendations: Torque specs are specific to your vehicle, and ignoring them can lead to safety issues. Always use the exact values provided by the manufacturer for your make and model.

4. Using Worn or Incorrect Tools: Using an improperly calibrated or worn torque wrench can lead to inaccurate torque readings. Ensure that your tools are in good working condition before use.

Frequently Asked Questions

Here are some FAQs about brake caliper torque specs –

1. What happens if I don’t torque brake caliper bolts properly?

If caliper bolts are under-torqued, they can come loose over time, leading to brake failure or misalignment of the caliper. Over-torquing the bolts can strip the threads, making it difficult to secure the caliper properly and potentially causing damage to the brake system.

2. Can I reuse brake caliper bolts?

Some manufacturers recommend replacing brake caliper bolts every time the caliper is removed, while others allow for reuse if the bolts are in good condition. Always follow the manufacturer’s recommendations. If the bolts appear worn, corroded, or damaged, replace them to ensure a secure fit.

3. Do I need to use a thread locker on brake caliper bolts?

Some manufacturers specify the use of thread locker on caliper bolts to prevent them from loosening due to vibration. Always follow your vehicle’s service manual for guidance on whether to apply thread locker or anti-seize.

4. Can I tighten brake caliper bolts without a torque wrench?

While it’s possible to tighten caliper bolts without a torque wrench, it’s not recommended. A torque wrench ensures you apply the precise amount of force needed to secure the bolts properly, reducing the risk of under- or over-tightening.

5. How often should I check my brake caliper bolts?

Brake caliper bolts typically do not need frequent checking unless you’re performing brake maintenance or hear unusual noises like rattling or knocking near the brakes. However, it’s a good idea to inspect them whenever you service your brakes or rotate your tires.

Conclusion

Proper installation of brake calipers is important for the safety and performance of your vehicle. Adhering to the manufacturer’s recommended torque specifications is key to preventing issues such as brake drag or caliper failure. It’s important to consult your vehicle’s manual for the specific torque values and to use a torque wrench to ensure accuracy.

Neglecting to properly torque your brake calipers can lead to costly repairs and even dangerous situations on the road. So take the time to do it right and stay safe out there on the road.