Brake calipers squeeze brake pads against the rotor to slow or stop the vehicle using hydraulic pressure. They come in two types: floating and fixed, and are essential for braking performance and safety. Regular maintenance ensures they work efficiently.

Brake calipers are a fundamental component in modern automotive braking systems. They play an important role in ensuring that your vehicle can slow down and stop effectively. While they might not receive as much attention as other parts of a car, brake calipers are essential for safety and performance.

In this article, we will delve deep into what brake calipers are, how they function, their types, the materials they are made from, and how they can affect the performance of your vehicle. We will also answer frequently asked questions to give you a clear understanding of this crucial component.

Contents

What are Brake Calipers?

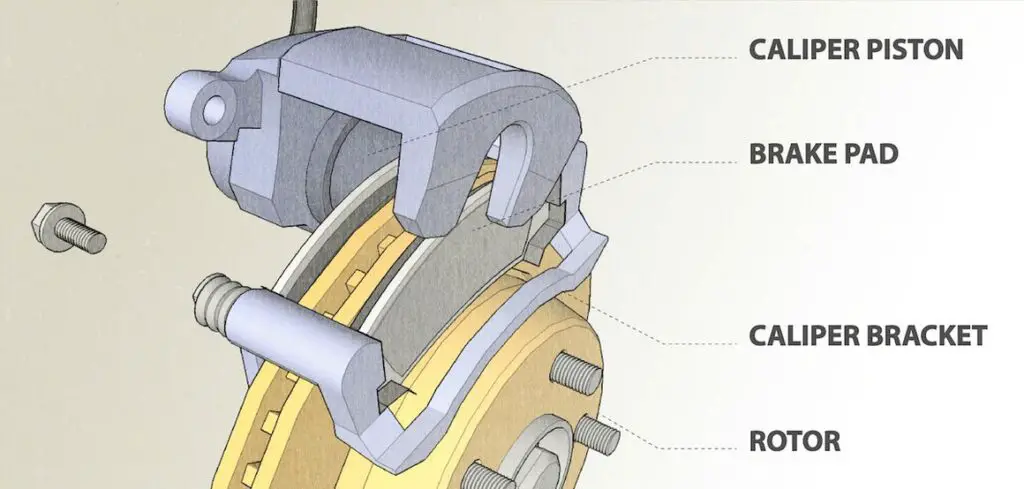

A brake caliper is a mechanical component of the disc brake system, responsible for squeezing the brake pads against the rotor (or disc) to create friction. This friction slows down the rotation of the wheels and, consequently, the vehicle.

Most modern cars use disc brakes on at least the front wheels, and brake calipers are the central part of this system. The caliper works as the “squeezer,” using hydraulic pressure to push the brake pads against the spinning rotor. As a result, the kinetic energy from the vehicle’s motion is converted into heat, which dissipates as the car slows down.

How Do Brake Calipers Work?

The brake caliper sits over the rotor like a clamp. The basic process of how it works is:

- Pressing the Brake Pedal: When the driver presses the brake pedal, the force is transferred through the brake lines to the brake caliper via hydraulic pressure, using brake fluid.

- Pistons in Action: Inside the caliper are one or more pistons. When hydraulic pressure builds up, these pistons push the brake pads outward.

- Friction on the Rotor: As the brake pads press against the rotor, the friction slows down the rotor’s rotation, reducing the vehicle’s speed.

- Releasing the Brake: Once the driver releases the brake pedal, the hydraulic pressure drops, and the pistons retract slightly. This allows the rotor to spin freely again without unnecessary friction from the brake pads.

Types of Brake Calipers

There are several types of brake calipers, each suited for different driving conditions and vehicle requirements. The two most common types are floating (or sliding) calipers and fixed calipers.

Floating (or Sliding) Calipers

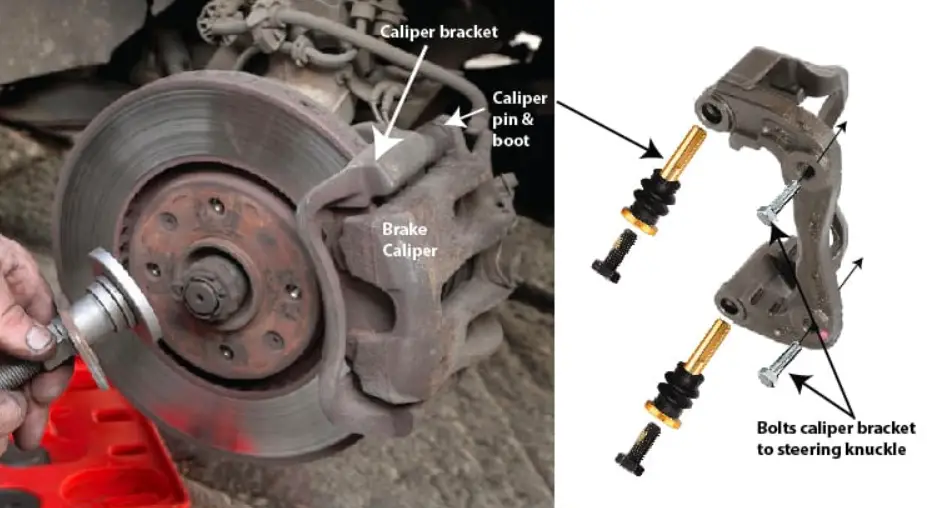

Floating calipers are the most common type found in vehicles today, especially in daily driving cars. They have a single piston on one side of the rotor and “float” on guide pins or bolts.

- How they work: When the piston pushes the brake pad on one side of the rotor, the caliper moves to push the opposite brake pad against the other side of the rotor.

- Advantages: They are lightweight, simple in design, and more affordable to produce. Floating calipers also provide adequate stopping power for most cars under typical driving conditions.

- Disadvantages: The movement of floating calipers can be less precise, which can lead to uneven brake pad wear over time. In high-performance or heavy-duty applications, they may not be as effective.

Fixed Calipers

Fixed calipers, as the name suggests, do not move relative to the rotor. Instead, they have pistons on both sides of the rotor, which press the brake pads simultaneously from both sides when hydraulic pressure is applied.

- How they work: When hydraulic pressure is applied, pistons on both sides push the brake pads against the rotor, providing balanced and consistent braking.

- Advantages: Fixed calipers provide better precision, better braking power, and reduced pad wear compared to floating calipers. They are often used in high-performance and sports cars.

- Disadvantages: Fixed calipers are more expensive, heavier, and complex to manufacture, making them less common in everyday vehicles.

High-Performance Calipers

In high-performance or racing applications, multi-piston calipers are often used. These can have anywhere from four to eight pistons. More pistons spread the braking force more evenly over the brake pads, increasing stopping power and reducing the risk of overheating.

- Advantages: More pistons result in better braking performance and more consistent pad wear. They are ideal for high-speed driving and track conditions.

- Disadvantages: They are significantly more expensive, heavier, and overkill for most daily driving needs.

Materials Used in Brake Calipers

Brake calipers need to withstand extreme conditions, from the high heat generated by friction to the constant exposure to the elements. Therefore, they are made from materials that offer strength, heat resistance, and durability.

Cast Iron

Cast iron is one of the most common materials used in brake calipers, especially in older models or heavier vehicles like trucks. It is known for its durability and heat resistance.

- Advantages: Cast iron calipers are robust and can handle high temperatures without warping or failing.

- Disadvantages: They are very heavy, which can affect the overall weight of the vehicle and reduce fuel efficiency.

Aluminum

Aluminum calipers are becoming increasingly popular, especially in modern cars and high-performance vehicles. They are lighter than cast iron, which helps reduce unsprung weight and improve fuel efficiency.

- Advantages: Aluminum calipers are lighter and provide a more responsive feel. They also dissipate heat faster, reducing the risk of brake fade.

- Disadvantages: They can be more expensive and may not be as strong as cast iron in extreme conditions.

Composite Materials

In some high-end or racing applications, composite materials like carbon-ceramic or titanium are used for calipers. These materials offer incredible heat resistance and weight savings but come at a much higher cost.

- Advantages: Composite calipers are extremely lightweight, resistant to corrosion, and can handle very high temperatures.

- Disadvantages: They are expensive and typically only used in specialized applications like racing or supercars.

Brake Caliper Maintenance

Regular maintenance of brake calipers is essential to ensure the safety and performance of your vehicle’s braking system. Some common maintenance tasks include:

- Inspecting for Wear and Tear: Over time, brake calipers can suffer from rust, corrosion, or damage to the seals that surround the pistons. It is important to check them regularly for signs of wear or leaking brake fluid.

- Lubricating Guide Pins: In floating calipers, the guide pins need to be lubricated to ensure smooth movement. If these become dry or corroded, it can lead to uneven pad wear.

- Replacing Brake Pads: Brake calipers are only as effective as the brake pads they push against the rotor. Ensure that your brake pads are replaced when worn to prevent damage to the rotors and maintain optimal braking performance.

- Bleeding the Brake Lines: Air in the brake lines can reduce the efficiency of the hydraulic system, causing a “spongy” brake pedal feel. Regularly bleeding the brakes to remove air ensures that the calipers operate effectively.

Frequently Asked Questions

Here are some FAQs about brake calipers explained

1. How long do brake calipers last?

On average, brake calipers last around 75,000 to 100,000 miles. However, this can vary depending on driving conditions, vehicle type, and maintenance. Regular inspection can help extend their lifespan.

2. Can I replace just one brake caliper?

It is possible to replace just one caliper, but it is generally recommended to replace both calipers on the same axle to ensure even braking performance and avoid potential safety issues.

3. What are the symptoms of a bad brake caliper?

Common signs of a failing brake caliper include pulling to one side when braking, uneven brake pad wear, a soft or spongy brake pedal, or leaking brake fluid.

4. Can I drive with a stuck brake caliper?

Driving with a stuck brake caliper is dangerous and can lead to further damage to the braking system, excessive wear on the brake pads and rotors, and even a potential loss of braking power.

5. Why do high-performance vehicles use multi-piston calipers?

Multi-piston calipers spread the braking force more evenly across the brake pads, which increases stopping power and reduces the risk of brake fade. This is particularly important in high-speed or performance driving conditions.

Conclusion

Brake calipers are an essential component of the braking system that play a critical role in your vehicle’s safety and performance. Understanding how they work, the different types available, and the materials used can help you make informed decisions when it comes to maintenance or upgrades. Regular inspection and maintenance will ensure that your brake calipers—and your entire braking system—function effectively for years to come.