Brake rotor turning is a process of resurfacing the brake rotor to remove imperfections and ensure smooth braking. It helps to extend the life of the rotor and improve braking performance.

Turning the rotor involves removing a small layer of metal from its surface using a lathe machine. This process is usually performed when the rotor becomes warped or develops grooves, causing vibration or noise during braking. It is an effective way to restore the rotor’s functionality without the need for complete replacement, saving time and money.

However, not all rotors can be turned, and it’s important to consult a professional mechanic to determine if this service is suitable for your vehicle.

Contents

What is Brake Rotor Turning?

Brake rotor turning, also called rotor resurfacing or machining, is a process where a thin layer of material is removed from the surface of the brake rotors. This is done to eliminate surface imperfections like grooves, glazing, or rust that can develop over time from constant contact with the brake pads. The goal is to restore the rotor’s smooth, flat surface, which improves brake pad contact and enhances braking performance.

Turning rotors involves using a lathe to shave off a minimal amount of metal from both sides of the rotor. The process restores the rotor’s surface to factory specifications, ensuring an even, flat surface for the brake pads to grip onto. However, it’s important to note that rotors have a minimum thickness limit. If they become too thin after turning, they’ll need to be replaced instead of resurfaced.

Why is Brake Rotor Turning Necessary?

Over time, your brake rotors undergo significant wear due to the friction generated when the brake pads press against them to slow down or stop the vehicle. This friction is necessary for braking, but it can cause the rotors to develop uneven surfaces, warping, or grooving. If the rotors become too uneven, it can lead to several issues:

- Reduced braking performance: Uneven rotors may cause the brake pads to lose proper contact with the rotor surface, leading to decreased stopping power.

- Brake pedal pulsation: Warped or uneven rotors can cause the brake pedal to pulse or vibrate when pressed, which affects the overall feel and response of the braking system.

- Noise and squealing: Grooved or damaged rotors can cause the brakes to squeal or make other noises, especially when coming to a stop.

- Increased brake pad wear: Damaged rotors can cause uneven brake pad wear, reducing the life of your pads and increasing the need for frequent replacement.

By turning the rotors, you restore a smooth, even surface, ensuring better brake pad contact, more effective stopping, and longer brake component life. However, rotor turning is only effective if the rotor still has enough thickness left after the process. If the rotor is too worn down, replacement is the safer and more viable option.

Is It Time to Turn Your Brake Rotors? Here’s How to Know

Knowing when to get your brake rotors turned is key to maintaining the safety and performance of your braking system. Here are some common signs that indicate it might be time for rotor resurfacing:

Brake Pedal Pulsation

If you notice pulsation or vibrations in the brake pedal when you press down, it’s often a sign of warped or uneven rotors. Rotor turning can smooth out the surface and eliminate the pulsation, resulting in a more consistent brake feel.

Squealing or Grinding Noises

Squealing, screeching, or grinding noises when braking are typically caused by worn brake pads, but if the pads are relatively new, the culprit could be uneven rotors. Rotor resurfacing can eliminate the grooves that cause these noises.

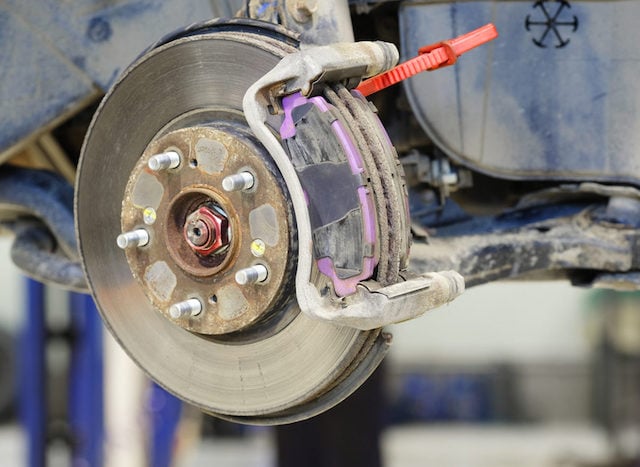

Visual Damage

When you inspect your rotors, look for visible grooves, scoring, or rust. If you notice these imperfections, it’s a sign the rotor’s surface is uneven, and resurfacing might be required.

Reduced Braking Power

If your vehicle’s stopping distance has increased or the brakes feel less responsive, uneven rotor surfaces might be preventing proper brake pad contact. Turning the rotors can help restore braking efficiency.

Brake Pad Replacement

If you’re replacing the brake pads, it’s a good idea to inspect the rotors at the same time. Even if the rotors aren’t showing obvious signs of damage, turning them during a pad replacement can ensure maximum performance and extend the life of your new pads.

Brake Rotor Turning vs. Brake Rotor Replacement

When your brake rotors show signs of wear or damage, you’ll need to decide whether to have them turned or replaced. Here’s a comparison to help you understand which option is better suited for your situation.

Brake Rotor Turning

Brake rotor turning, also known as resurfacing, is the process of machining the surface of the rotors to remove minor imperfections, such as grooves, scoring, and uneven wear. The goal is to create a smooth, even surface that ensures proper contact with the brake pads.

- Pros:

- Cost-effective: Turning rotors is usually cheaper than replacing them outright.

- Restores smooth surface: Rotor turning eliminates surface imperfections and improves braking performance.

- Prolongs rotor life: If the rotors are still within the manufacturer’s thickness specifications, turning them can extend their life.

- Cons:

- Limited by rotor thickness: Rotors can only be turned a certain number of times before they become too thin to be safe. If they fall below the minimum thickness, replacement is necessary.

- Temporary fix: Turning rotors is not a permanent solution. The rotors will eventually wear out again and need to be replaced.

Brake Rotor Replacement

Brake rotor replacement involves removing the old rotors and installing new ones. This option is necessary when the rotors are too damaged to be resurfaced or when they have worn below the manufacturer’s minimum thickness.

- Pros:

- Restores full performance: New rotors restore full braking performance and often result in quieter, smoother braking.

- Better for severely damaged rotors: If your rotors are cracked, severely warped, or too thin, replacing them is the safest option.

- Longer lifespan: New rotors will last longer than turned ones, as turning removes material and makes the rotors thinner.

- Cons:

- More expensive: Replacing rotors is more costly than turning them.

- Not always necessary: In some cases, rotor turning is sufficient, and replacement may not be required.

Ultimately, the decision to turn or replace your rotors depends on their condition and thickness. If they are still within safe thickness limits and show only minor surface imperfections, rotor turning is a cost-effective way to restore performance. However, if the rotors are excessively worn, warped, or cracked, replacement is the safer option.

The Process of Brake Rotor Turning

If your rotors need resurfacing, here’s what the process generally involves:

Step 1: Inspection

Before turning the rotors, the mechanic will inspect them for signs of wear, warping, scoring, and measure their thickness. The rotor must meet the manufacturer’s minimum thickness specification to be turned safely.

Step 2: Rotor Removal

The brake rotors are removed from the vehicle. This requires disassembling the brake caliper and sometimes the wheel hub, depending on the vehicle.

Step 3: Mounting on the Lathe

The rotors are mounted on a specialized lathe designed for brake rotor resurfacing. The lathe cuts a thin layer of metal off the surface of the rotor to remove imperfections and create a smooth, flat surface.

Step 4: Precision Cutting

The technician will take multiple light cuts to ensure that both sides of the rotor are evenly machined and any warping or scoring is removed.

Step 5: Reinstallation

Once the rotors have been resurfaced, they are reinstalled on the vehicle, and the braking system is reassembled.

Step 6: Testing

After the rotors are reinstalled, the mechanic will test the braking system to ensure everything is working correctly and the pedal feel is smooth.

How to Maintain Brake Rotors

To extend the life of your brake rotors and minimize the need for turning or replacement, regular maintenance is essential:

- Brake Pad Replacement: Replace the brake pads before they are completely worn down to avoid rotor damage.

- Drive Smoothly: Avoid harsh braking or riding the brakes for long periods, as this generates excessive heat and can warp rotors.

- Regular Inspections: Have your brakes inspected regularly, especially if you notice any changes in performance or unusual noises.

- Keep Rotors Clean: Rust and debris can accelerate rotor wear. If you live in an area with a lot of road salt or moisture, clean your rotors regularly to prevent corrosion.

Frequently Asked Questions

Here are some FAQs about brake rotor turning –

1. How much does it cost to get rotors turned?

Rotor turning typically costs between $15 and $30 per rotor, depending on your location and the shop you visit. This is generally cheaper than replacing rotors, which can range from $30 to over $100 per rotor.

2. How many times can rotors be turned?

Rotors can usually be turned 1-2 times before they reach the minimum thickness limit set by the manufacturer. Once they are too thin, they will need to be replaced.

3. Can I turn my rotors at home?

Turning rotors requires specialized equipment, such as a brake lathe, which is not commonly available for home use. It’s best to have a professional mechanic perform rotor turning.

4. How long do brake rotors last before needing turning or replacement?

The lifespan of brake rotors depends on driving habits, vehicle type, and rotor material. On average, rotors can last between 30,000 to 70,000 miles, but they may need turning or replacement earlier if they experience severe wear or damage.

5. Should I always turn rotors when replacing brake pads?

Not necessarily. If the rotors are in good condition and meet the thickness specifications, they may not need turning. However, turning the rotors can help ensure smooth contact between the new pads and the rotor surface.

Conclusion

Brake rotor turning is a cost-effective way to restore the smooth surface of your rotors and improve braking performance. However, it’s essential to monitor rotor thickness and overall condition to ensure safe operation. Regular brake maintenance, including pad replacement and rotor inspections, will keep your braking system in optimal shape, providing you with the peace of mind that your vehicle can stop safely when needed.