The crankshaft position sensor monitors the position and rotational speed of the crankshaft, providing critical data to the engine control module (ECM). This information is used to control ignition timing, fuel injection, and engine synchronization, ensuring optimal engine performance and efficiency. Without this sensor, the engine may misfire, stall, or fail to start.

The crankshaft position sensor (CKP) is a vital component in modern internal combustion engines. This small but crucial sensor plays an essential role in ensuring that your engine runs smoothly and efficiently. Without it, your vehicle would struggle to start, misfire, or even stall.

Contents

What is a Crankshaft Position Sensor?

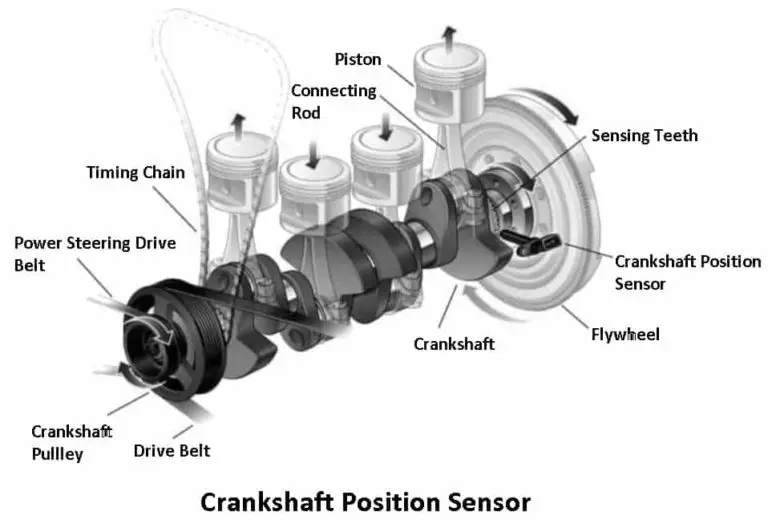

The crankshaft position sensor is an electronic device found in virtually all modern vehicles. It’s typically located near the crankshaft, either mounted on the engine block, the timing cover, or near the flywheel.

The sensor’s primary function is to monitor the position and rotational speed (RPM) of the crankshaft, which is the engine’s primary rotating component. The data collected by the CKP sensor is critical for controlling fuel injection, ignition timing, and other engine functions.

How Does the Crankshaft Position Sensor Work?

The crankshaft position sensor works by detecting the position and speed of the crankshaft as it rotates. There are different types of CKP sensors, including:

- Magnetic Sensors: These sensors use a magnetic field and a reluctor wheel attached to the crankshaft. As the reluctor wheel rotates, it disrupts the magnetic field, generating a voltage signal. This signal is then sent to the engine control module (ECM).

- Hall Effect Sensors: Hall effect sensors generate a digital signal as the crankshaft rotates. A magnetic field is altered by the rotating crankshaft, causing the sensor to produce a series of voltage pulses that correspond to the crankshaft’s position and speed.

- Optical Sensors: Although less common, optical sensors use a light-emitting diode (LED) and a phototransistor to detect the position of the crankshaft. As the crankshaft rotates, it interrupts the light beam, creating a signal that the ECM can interpret.

Regardless of the type, the sensor’s signal is sent to the ECM, which uses the information to calculate the exact position of the crankshaft at any given moment. This data is critical for determining when to inject fuel into the cylinders and when to ignite the air-fuel mixture.

Crankshaft Position Sensor Function

The crankshaft position sensor serves several essential functions in an engine:

1. Timing Control

One of the primary roles of the crankshaft position sensor is to provide precise timing information to the ECM. The ECM uses this data to control the timing of the spark plugs and fuel injectors. Proper timing ensures that the air-fuel mixture is ignited at the right moment, which is crucial for engine efficiency and power.

2. Fuel Injection Control

The CKP sensor also plays a vital role in controlling the fuel injection system. By knowing the exact position of the crankshaft, the ECM can determine the optimal time to inject fuel into each cylinder. This precise control helps improve fuel efficiency, reduce emissions, and maximize engine performance.

3. Engine Synchronization

The CKP sensor ensures that the engine’s components, such as the camshaft and crankshaft, are synchronized. This synchronization is crucial for the engine’s overall operation, as it ensures that the valves open and close at the correct times relative to the pistons’ positions.

4. Misfire Detection

The ECM relies on the CKP sensor to detect engine misfires. If the sensor detects irregularities in the crankshaft’s rotation, it can signal a misfire, which triggers the check engine light. This early detection helps prevent further engine damage and allows for timely repairs.

5. Engine Starting

The crankshaft position sensor is also critical during engine startup. The ECM needs to know the crankshaft’s position to initiate the first spark and fuel injection. If the sensor fails, the engine may struggle to start or fail to start altogether.

Source: theengineerspost.com

Importance of the Crankshaft Position Sensor

The crankshaft position sensor is integral to the overall operation of your vehicle’s engine. Here’s why it’s so important:

1. Engine Performance

Without accurate data from the CKP sensor, the ECM cannot properly control the timing of the engine’s components. This can lead to poor engine performance, including rough idling, stalling, and loss of power.

2. Fuel Efficiency

A properly functioning CKP sensor helps the ECM optimize fuel injection, leading to better fuel efficiency. A faulty sensor can cause the engine to run rich or lean, resulting in increased fuel consumption and higher emissions.

3. Emissions Control

The crankshaft position sensor plays a role in reducing vehicle emissions. By ensuring that the engine runs efficiently, the sensor helps minimize the production of harmful pollutants, making your vehicle more environmentally friendly.

4. Engine Longevity

Timely and accurate data from the CKP sensor prevents engine misfires and other issues that can cause long-term damage. This, in turn, helps extend the life of your engine by ensuring it operates within its designed parameters.

Frequently Asked Questions

Here are some FAQs about the function of crankshaft position sensor –

1. What happens if the crankshaft position sensor fails?

If the CKP sensor fails, the engine may not start, or it could stall while driving. You may also experience poor acceleration, engine misfires, and a check engine light.

2. Can I drive with a bad crankshaft position sensor?

It’s not recommended to drive with a bad CKP sensor. The engine may run poorly, and you risk stalling or experiencing a complete engine shutdown, which can be dangerous.

3. How much does it cost to replace a crankshaft position sensor?

The cost to replace a CKP sensor varies depending on the vehicle make and model but typically ranges between $100 and $300, including labor.

4. How long does a crankshaft position sensor last?

A crankshaft position sensor can last the lifetime of the vehicle, but it may wear out over time due to heat, vibration, and oil contamination. Regular maintenance can help prolong its life.

5. Can a crankshaft position sensor be cleaned?

In some cases, cleaning the CKP sensor can restore its function, especially if it’s contaminated with oil or debris. However, if the sensor is damaged, it will need to be replaced.

Related Article

How to Turn a Crankshaft Manually

Conclusion

The crankshaft position sensor is a critical component of your vehicle’s engine management system. It provides essential data that allows the ECM to control fuel injection, ignition timing, and other key functions. If you suspect your crankshaft position sensor is failing, it’s essential to address the issue promptly to keep your engine running smoothly.