Turning a crankshaft manually can be a daunting task, but it’s essential in some circumstances. Whether you’re checking the engine’s compression, replacing a timing belt, or rebuilding the engine, turning the crankshaft manually is necessary. In this article, we will discuss how to turn a crankshaft manually, the tools you need, and some safety precautions you should take.

Contents

What is a Crankshaft and Why do Need to Turn it Manually?

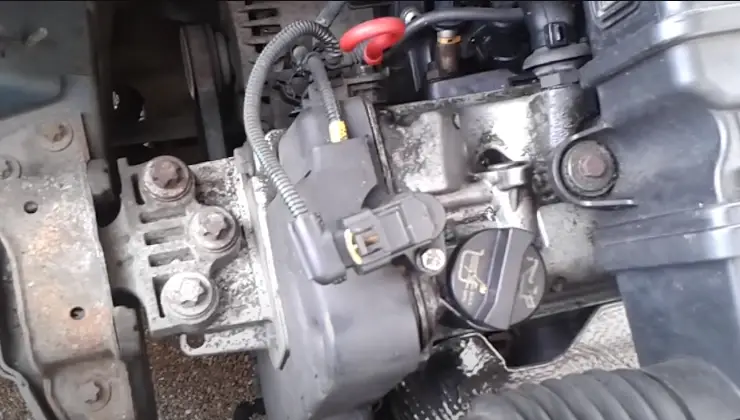

A crankshaft is a vital component of an engine that converts linear motion into rotational motion. It’s responsible for providing the power that propels the vehicle forward. Need to turn the crankshaft manually for various reasons, such as checking the engine’s compression, replacing the timing belt, or rebuilding the engine.

How to Turn a Crankshaft Manually: Step-by-Step Guide

Turning a crankshaft manually requires some preparation and care to avoid damaging the engine. Here’s a step-by-step guide on how to turn a crankshaft manually:

Step 1: Prepare the Engine

Before turning the crankshaft manually, you need to prepare the engine. Start by removing the air filter and disconnecting the battery to prevent the engine from accidentally starting. You should also remove the belts and accessories that may interfere with the crankshaft’s rotation.

Step 2: Remove the Spark Plugs

Remove the spark plugs to relieve the compression in the engine. This will make it easier to turn the crankshaft manually.

Step 3: Position the Engine Correctly

Position the engine correctly to access the crankshaft. You can use the service manual or consult with a mechanic to ensure that the engine is in the correct position.

Step 4: Use a Wrench to Turn the Crankshaft

Using a wrench, turn the crankshaft in the direction indicated by the service manual or the mechanic. You should work slowly and carefully to avoid applying excessive force that may damage the engine.

Step 5: Check for Proper Rotation

After turning the crankshaft a few times, check for proper rotation. The engine should turn smoothly and without any resistance. If you encounter any resistance, stop immediately and check for any potential issues.

Tips for Turning a Crankshaft Manually

Here are some tips that can help you turn a crankshaft manually more efficiently and safely:

Use a Crankshaft Turning Tool

Using a crankshaft turning tool can help you turn the crankshaft more easily and with less force. It also reduces the risk of damaging the engine.

Use a Socket Wrench with a Long Handle

Using a socket wrench with a long handle can provide you with better leverage and make it easier to turn the crankshaft.

Work Slowly and Carefully

Working slowly and carefully can help you avoid applying excessive force that may damage the engine. It also allows you to detect any potential issues before they escalate.

Use the Right Amount of Force

Using the right amount of force is crucial when turning a crankshaft manually. Applying too much force can damage the engine, while applying too little force can prevent the engine from turning.

Safety Precautions for Turning a Crankshaft Manually

Turning a crankshaft manually can be dangerous if proper safety precautions are not taken. Here are some safety precautions you should take:

Wear Protective Gear: Wear protective gear, such as gloves and safety glasses, to protect yourself from any potential injuries.

Ensure Proper Engine Positioning: Ensuring proper engine positioning can prevent the engine from accidentally starting, which can be dangerous.

Use the Correct Tools: Using the correct tools can prevent damage to the engine and ensure that the crankshaft is turned correctly.

Frequently Asked Questions

Here are some frequently asked questions about turning a crankshaft manually:

Q: Can You Damage an Engine by Turning the Crankshaft Manually?

A: Yes, applying excessive force or turning the crankshaft in the wrong direction can damage the engine.

Q: Is It Possible to Turn a Crankshaft Manually Without Removing the Engine?

A: Yes, it’s possible to turn a crankshaft manually without removing the engine. However, you may need to remove certain components, such as belts and accessories, to access the crankshaft.

Q: How Do You Determine the Direction to Turn the Crankshaft?

A: You can determine the direction to turn the crankshaft by consulting the service manual or a mechanic. The direction may vary depending on the engine’s make and model.

Q: What Happens If You Turn the Crankshaft in the Wrong Direction?

A: Turning the crankshaft in the wrong direction can damage the engine, especially if you apply excessive force.

Q: How Do You Check for Proper Rotation After Turning the Crankshaft?

A: You can check for proper rotation by turning the crankshaft a few times and checking for smooth and uninterrupted rotation. If you encounter any resistance, stop immediately and check for any potential issues.

Q: Can You Turn the Crankshaft Manually If the Engine is seized?

A: If the engine is seized, turning the crankshaft manually may not be possible. You may need to consult with a mechanic to diagnose and fix the issue.

Q: Do You Need Special Training to Turn a Crankshaft Manually?

A: While it’s not necessary to have special training to turn a crankshaft manually, it’s essential to follow the proper procedures and safety precautions to avoid injury or engine damage.

Conclusion

Turning a crankshaft manually is a necessary procedure when working on an engine. By following the proper procedures and safety precautions, you can turn the crankshaft safely and efficiently. Remember to consult with a service manual or mechanic and use the correct tools to prevent any potential issues.