Exhaust manifold torque specs refer to the specific amount of force required to tighten the bolts securing the exhaust manifold to the engine. Proper torque ensures a tight seal, preventing exhaust leaks and avoiding damage to the manifold or gasket. Following the manufacturer’s recommended torque values is essential to prevent over-tightening, which can lead to warping or broken bolts, and under-tightening, which can cause exhaust leaks.

When it comes to vehicle maintenance, ensuring that the exhaust manifold is properly installed is essential for the overall health and efficiency of your engine. One critical aspect of this is tightening the manifold bolts to the correct torque specifications. Incorrect torque can lead to exhaust leaks, warped manifolds, broken bolts, or damage to the gasket, all of which can severely impact engine performance.

Contents

What Are Torque Specs?

Torque specifications (torque specs) refer to the specific amount of force applied to a fastener, such as a bolt or nut, during tightening. Torque is measured in units such as pound-feet (lb-ft) or Newton-meters (Nm), and it’s critical to follow the manufacturer’s recommended torque settings to ensure that parts are securely fastened without causing damage.

In the case of exhaust manifolds, proper torque specs ensure a snug fit between the manifold, gasket, and cylinder head. This prevents exhaust leaks, ensures even distribution of heat, and reduces the risk of warping due to uneven pressure.

Why Exhaust Manifold Torque Specs Are Important

Tightening the exhaust manifold bolts to the correct torque specs is crucial for several reasons:

- Prevent Exhaust Leaks: Properly torquing the manifold bolts ensures that the gasket forms an effective seal between the manifold and the engine head. Under-torquing can lead to exhaust gases escaping, which can cause performance issues and increased emissions.

- Avoid Warping: Over-torquing the manifold can warp the metal, leading to uneven surfaces and future leaks. Warped exhaust manifolds can also create hot spots, leading to premature failure.

- Prevent Broken Bolts: Over-tightening can also result in broken or stripped bolts, which are difficult and time-consuming to repair. Using the correct torque settings avoids this risk and ensures a reliable fit.

- Heat Management: The exhaust manifold experiences extreme heat from the engine, which causes expansion and contraction. Bolts tightened to the right specs will hold the manifold securely through these temperature changes, preventing excessive stress on the manifold and gasket.

Common Exhaust Manifold Torque Specs

Torque specifications vary depending on the vehicle’s make, model, engine size, and the type of exhaust manifold. Below are some general torque ranges for common vehicles. Always refer to the vehicle’s service manual for the exact specifications for your particular model.

- General 4-cylinder engines: 18-30 lb-ft (24-40 Nm)

- V6 engines: 25-40 lb-ft (34-54 Nm)

- V8 engines: 20-35 lb-ft (27-47 Nm)

Different types of exhaust manifold bolts may have unique torque specs as well, depending on the material of the bolts and the manifold. Always follow the manufacturer’s recommendations closely to avoid issues.

How to Tighten Exhaust Manifold Bolts

Properly tightening exhaust manifold bolts is not as simple as using a wrench and tightening everything as hard as possible. There is a step-by-step process to ensure that the bolts are tightened correctly and evenly. Here’s a breakdown of how to do it:

1. Clean the Surface

Before installing the manifold, make sure both the engine head and the manifold surface are clean and free from debris. Any leftover gasket material or dirt can interfere with proper sealing and torque distribution.

2. Install the New Gasket

Place the exhaust manifold gasket in position between the cylinder head and the manifold. Ensure it aligns with all bolt holes and exhaust ports.

3. Insert the Bolts

Start by hand-threading the manifold bolts into place. This ensures they go in straight and reduces the risk of cross-threading.

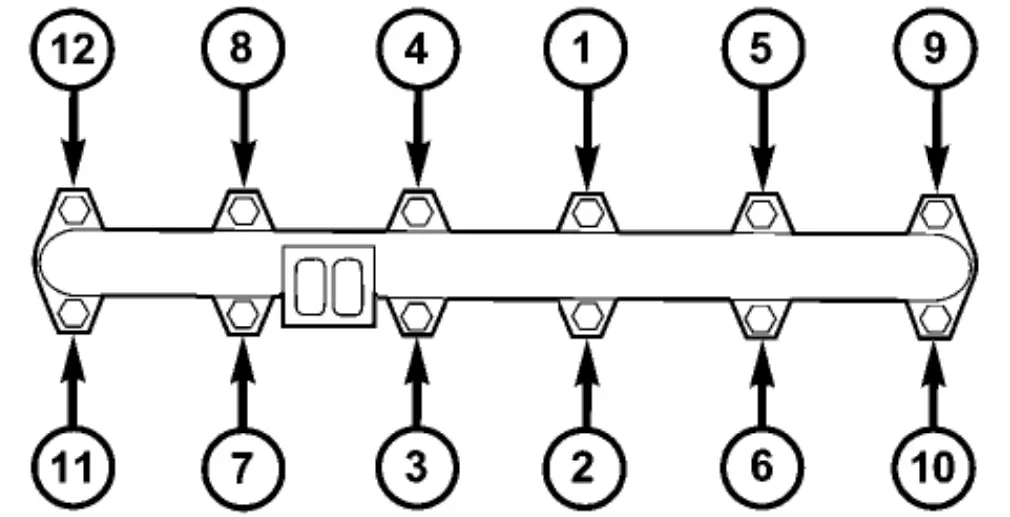

4. Follow a Bolt Tightening Sequence

To avoid warping the manifold, always follow the recommended bolt tightening sequence. This sequence typically begins with the center bolts and works outward in a criss-cross or spiral pattern. This ensures even pressure is applied across the entire manifold.

5. Use a Torque Wrench

Using a torque wrench is essential for getting the correct tightness. Set your torque wrench to the specified torque value for your vehicle and tighten each bolt in the sequence. Remember to check the torque settings periodically during the process.

6. Retorque After Heat Cycling

After the engine has run and the manifold has been exposed to heat, some settling may occur. It’s a good idea to retorque the manifold bolts after the first heat cycle to ensure that everything remains tight.

Factors That Influence Torque Specs

While torque specs for exhaust manifolds are provided by the vehicle manufacturer, a few factors can affect how these specs should be applied:

1. Material of Bolts and Gaskets: Different materials expand and contract at different rates. For example, a steel manifold expands less than a cast iron one. Similarly, copper gaskets may require different torque settings compared to composite gaskets. Always ensure that the torque specs you are using are specific to the materials in use.

2. Use of Anti-Seize or Thread Locker: In some cases, a mechanic might apply anti-seize compound to the threads to prevent bolts from sticking due to corrosion. However, anti-seize can alter the friction between the bolt and the cylinder head, potentially requiring lower torque settings. Conversely, using a thread locker might require slightly higher torque specs.

3. Engine Type: Engines with forced induction (such as turbochargers or superchargers) experience higher exhaust gas temperatures, which can affect the torque needed for exhaust manifold bolts. Turbocharged engines may require higher torque specs due to the increased thermal expansion.

4. Heat Cycles: Exhaust manifolds undergo constant heating and cooling cycles. Over time, bolts may loosen due to the expansion and contraction of the metal. For this reason, it’s important to follow up with a torque check after running the engine for the first time after the initial installation.

Signs That Exhaust Manifold Bolts Are Not Properly Torqued

Improperly torqued exhaust manifold bolts can lead to several performance and mechanical issues. Here are some signs to look out for:

- Exhaust Leaks: If the manifold bolts are not properly tightened, exhaust gases may escape through small gaps between the manifold and the cylinder head. This can cause a hissing or ticking sound, reduced engine performance, and increased emissions.

- Warpage or Cracking: Over-torquing the bolts can cause the manifold to warp or crack over time. This damage is often irreversible and may require replacing the entire manifold.

- Exhaust Manifold Gasket Failure: Insufficient torque can cause the manifold gasket to fail prematurely. This may result in an exhaust leak, loss of power, or an increase in engine noise.

- Broken or Stripped Bolts: Applying too much torque can cause bolts to break or strip, making removal and replacement more difficult.

Frequently Asked Questions

Here are some FAQs about exhaust manifold torque specs –

1. What happens if I don’t torque the exhaust manifold bolts correctly?

Incorrect torque can lead to exhaust leaks, warped manifolds, or broken bolts. If the bolts are under-torqued, gases can escape, leading to performance issues. If they are over-torqued, you risk damaging the manifold or the bolts.

2. Can I use a regular wrench instead of a torque wrench for exhaust manifold bolts?

While a regular wrench can be used, it’s not recommended. A torque wrench ensures you apply the correct amount of force, preventing over-tightening or under-tightening, both of which can lead to mechanical issues.

3. Do I need to re-torque the exhaust manifold bolts after installation?

Yes, after the manifold has gone through a heat cycle, the bolts may loosen slightly due to expansion and contraction. It’s recommended to re-torque them after the engine has cooled down following its first run.

4. Can I reuse exhaust manifold bolts?

It depends on the type of bolts used. Some exhaust manifold bolts are designed to be reusable, while others are torque-to-yield (TTY) bolts and must be replaced once removed. Check your vehicle’s service manual for recommendations.

5. What should I do if I break an exhaust manifold bolt while torquing it?

If a bolt breaks, you will need to extract it, which can be difficult. You may be able to use an extraction tool, but in some cases, it may require professional help. It’s essential to follow torque specs carefully to avoid breaking bolts.

Conclusion

Exhaust manifold torque specs are crucial for ensuring the proper functioning of your vehicle’s exhaust system. Following the correct torque values helps prevent exhaust leaks, warping, and damage to both the manifold and the engine. Always refer to the manufacturer’s guidelines, use a torque wrench, and retorque the bolts after the first heat cycle. Taking the time to tighten the bolts correctly will help ensure a long-lasting and efficient exhaust system, avoiding costly repairs down the road.