To determine the correct Holley power valve size, measure your engine’s manifold vacuum at idle using a vacuum gauge. Then, apply the “half-vacuum rule,” selecting a power valve with a rating approximately half of your measured idle vacuum (e.g., if your vacuum is 14 inHg, choose a 7.0 inHg valve). Testing and fine-tuning may be needed to optimize performance based on driving conditions.

For those familiar with carbureted engines, Holley carburetors are among the most popular and widely used. One of the essential components in these carburetors is the power valve, which plays a critical role in fuel delivery under heavy throttle or load. The power valve helps optimize the air-fuel ratio by delivering additional fuel when the engine requires it, particularly during acceleration.

However, selecting the correct power valve size is crucial for ensuring optimal engine performance and avoiding issues such as backfires or running too rich or too lean. In this post, we will explore how to determine the correct Holley power valve size, the factors influencing its selection, and why getting it right is so important.

Contents

What is a Holley Power Valve?

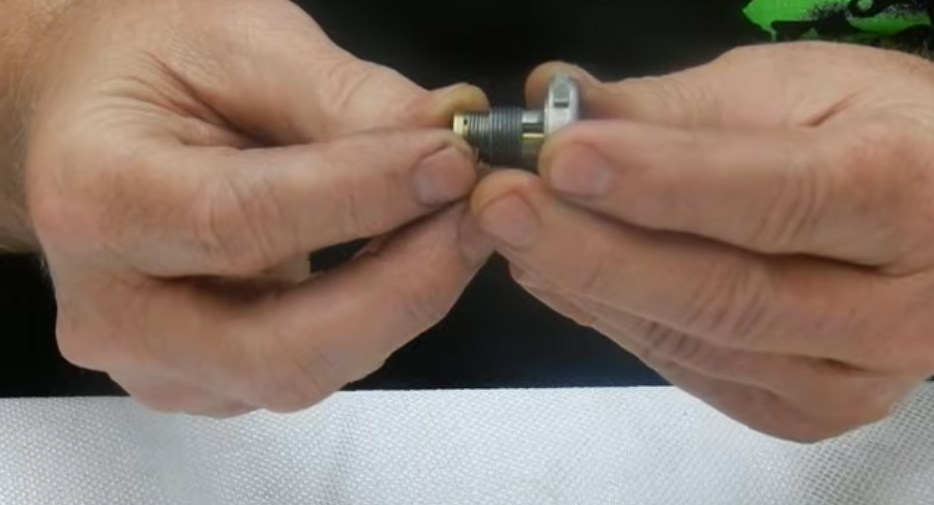

A power valve is a vacuum-actuated device located in the carburetor’s metering block. Its primary function is to regulate the flow of fuel into the engine when the engine is under load or in wide-open throttle conditions. At cruising speeds or light throttle, the power valve remains closed, preventing extra fuel from entering the system. However, when the engine encounters increased load, and vacuum drops below a specific threshold, the power valve opens, allowing additional fuel to flow into the carburetor.

This additional fuel is necessary for maintaining the correct air-fuel mixture during acceleration, avoiding lean conditions that could lead to engine damage. Thus, choosing the proper power valve size is crucial for maintaining engine performance and reliability.

Power Valve Ratings

Holley power valves are rated based on vacuum, typically expressed in inches of mercury (inHg). The rating refers to the vacuum level at which the valve opens. For instance, a power valve rated at 6.5 inHg will open when engine vacuum drops below 6.5 inHg. The power valve must be carefully matched to the engine’s vacuum characteristics to ensure proper fuel delivery.

There are two key factors to consider when choosing a power valve size:

- Engine Manifold Vacuum: This is the primary factor that influences the selection of the power valve. Manifold vacuum varies depending on engine load and throttle position. Power valves are usually selected based on the engine’s vacuum at idle in neutral or park.

- Engine Operating Conditions: The power valve should be chosen based on how the vehicle will be driven. For example, high-performance engines that frequently experience wide-open throttle or heavy load conditions may require a different power valve size than a daily-driven street vehicle.

How to Determine Holley Power Valve Size

To determine the correct size for your Holley power valve, follow these steps:

- Measure Manifold Vacuum at Idle:

- The first and most critical step is to measure the engine’s manifold vacuum at idle. Use a vacuum gauge to measure the engine’s vacuum while it’s running in neutral or park. Make sure the engine is fully warmed up and at operating temperature.

- For most street-driven vehicles, this reading will typically fall between 14 and 18 inches of mercury (inHg), depending on engine specifications and camshaft profile.

- Determine the Half-Vacuum Rule:

- Once you have the manifold vacuum reading, apply the “half-vacuum rule” to select the power valve size. The general rule is to choose a power valve rated at approximately half of your measured idle vacuum. For instance, if your engine’s vacuum at idle is 14 inHg, you would select a power valve rated around 7.0 inHg.

- This method ensures that the power valve remains closed during light throttle and cruising conditions but opens to supply additional fuel when the vacuum drops under heavy load or acceleration.

- Consider Special Conditions (Performance or Racing Engines):

- If your engine is highly modified or built for racing, you may need to deviate from the half-vacuum rule. High-performance or race engines typically have lower vacuum at idle due to aggressive camshaft profiles. In such cases, it’s essential to experiment with power valve sizes to find the one that best suits the engine’s performance characteristics.

- Additionally, high-performance vehicles that see wide-open throttle regularly may benefit from power valves with slightly lower vacuum ratings to ensure they open sooner during acceleration.

- Test and Fine-Tune:

- Once you have selected a power valve based on your vacuum reading, it’s crucial to test the vehicle under different driving conditions. Monitor engine performance, especially under heavy throttle or load, to see if the power valve is supplying enough fuel.

- If the engine feels sluggish, hesitates, or backfires under load, it may be an indication that the power valve is either opening too late (high vacuum rating) or not providing enough fuel. In this case, try a power valve with a lower rating (e.g., 6.5 to 5.5 inHg).

- Conversely, if the engine runs too rich or exhibits excessive fuel consumption at cruising speeds, the power valve may be opening too early. A higher-rated power valve may be required in this scenario.

Power Valve Selection Example

Let’s walk through an example of selecting a power valve size:

- Step 1: Measure Vacuum

Suppose you have a street-driven small-block V8 engine. After warming up the engine and measuring vacuum at idle, you find that it pulls 13 inHg. - Step 2: Apply the Half-Vacuum Rule

Using the half-vacuum rule, you would divide 13 inHg by 2, giving you a recommended power valve size of 6.5 inHg. - Step 3: Install and Test

You install a 6.5 inHg power valve and test the vehicle under various conditions, including cruising, light throttle, and heavy acceleration. If the engine runs smoothly under all conditions and does not hesitate or run rich, the 6.5 power valve is correctly matched to your engine.

However, if you notice any performance issues, further adjustments may be needed by testing different power valve sizes until the optimal one is found.

Why to Choose the Right Power Valve

Selecting the correct power valve size is crucial for ensuring proper engine performance and longevity. If the power valve opens too soon (low vacuum rating), the engine will run rich at cruising speeds, leading to poor fuel economy and potential fouling of spark plugs. If the power valve opens too late (high vacuum rating), the engine could run lean under load, risking engine damage due to inadequate fuel delivery.

By carefully measuring vacuum and choosing the right power valve, you can optimize your engine’s performance, improve throttle response, and ensure smooth operation under various driving conditions.

Frequently Asked Questions

Here are some FAQs about selecting the Holley power valve size –

1. What happens if the power valve is too big?

A power valve with too high a vacuum rating (e.g., 10.5 inHg) will open too late, potentially causing the engine to run lean during acceleration. This can result in poor throttle response and, in extreme cases, engine damage due to insufficient fuel delivery under load.

2. Can a power valve cause backfiring?

Yes, if the power valve is too small or fails to open when needed, the engine can run lean, leading to backfiring through the intake manifold or carburetor. This typically occurs when the air-fuel mixture is too lean under load.

3. How often should I check my Holley power valve?

Power valves do not typically require frequent maintenance, but it’s a good idea to inspect them during regular carburetor maintenance, especially if you notice performance issues like poor acceleration or backfiring.

4. What is the difference between a single-stage and two-stage power valve?

Single-stage power valves open at a specific vacuum level and allow fuel enrichment at once. Two-stage power valves, on the other hand, have two levels of enrichment and provide fuel in a more gradual manner, making them more suited for engines that require more precise fuel control during varying load conditions.

5. Can a faulty power valve affect fuel economy?

Yes, a faulty or incorrectly sized power valve can negatively impact fuel economy. If the valve opens too early, it can cause the engine to run rich, consuming excess fuel during normal driving conditions. Conversely, if it opens too late, the engine may run lean, which can affect overall performance and efficiency.

Conclusion

In conclusion, determining the correct Holley power valve size is essential for ensuring your engine operates efficiently under various load conditions. By measuring the engine’s manifold vacuum at idle and applying the half-vacuum rule, you can select a power valve that provides the right amount of fuel enrichment when needed.

Proper selection not only optimizes performance but also prevents potential issues such as running too rich or too lean. Testing and fine-tuning are crucial to achieving the best results, especially in high-performance or modified engines.