A car’s water pump circulates coolant through the engine to regulate temperature. It uses an impeller to push coolant from the radiator through the engine and back, ensuring the engine doesn’t overheat.

The water pump is a crucial component of a car’s cooling system, ensuring that the engine operates within a safe temperature range. Despite its importance, the water pump often goes unnoticed until it fails, leading to engine overheating and potential damage. This blog post will delve into how a water pump works in a car, its components, common issues, and maintenance tips to keep your vehicle running smoothly.

Contents

Water Pump’s Role in Engine Cooling

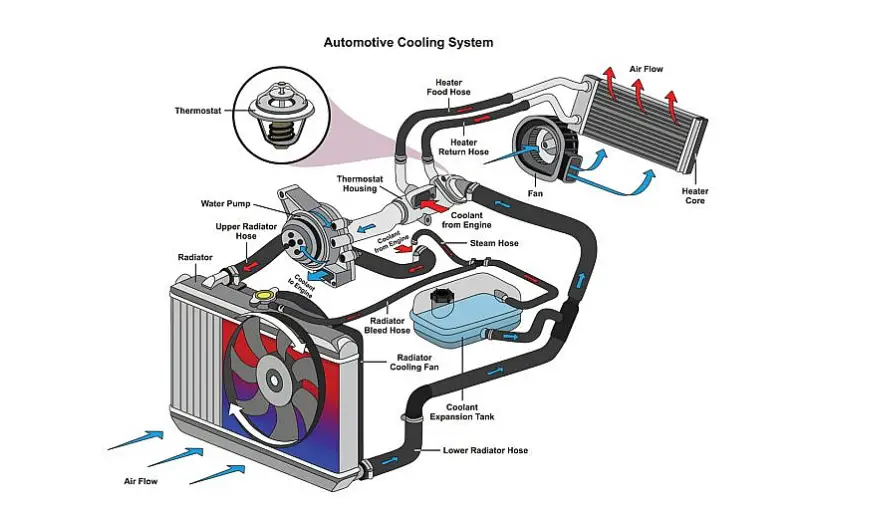

The internal combustion engine generates a significant amount of heat during operation. To prevent overheating, a cooling system circulates coolant—a mixture of water and antifreeze—through the engine. The water pump is responsible for driving this coolant through the engine block, cylinder head, radiator, and heater core, maintaining a constant flow to dissipate heat effectively.

The Cooling System Cycle

- Coolant Circulation: The water pump draws coolant from the radiator and forces it into the engine block and cylinder head, where it absorbs heat from the engine.

- Heat Dissipation: After absorbing heat, the coolant exits the engine and flows back to the radiator. Here, it is cooled by air passing through the radiator fins, typically assisted by the cooling fan.

- Return Flow: The cooled coolant is then returned to the water pump, and the cycle repeats.

This continuous cycle ensures that the engine temperature stays within the optimal range, preventing damage from excessive heat.

Components of a Water Pump

A typical car water pump is a simple but robust assembly designed to last thousands of miles. Understanding its components can help in diagnosing issues and performing maintenance.

- Impeller: The impeller is the heart of the water pump. It is a fan-like structure that spins to move the coolant through the system. Made of metal or plastic, the impeller’s design allows it to create a centrifugal force, pushing the coolant outward and into the engine block.

- Housing: The pump housing encloses the impeller and provides channels for coolant flow. It is usually made of cast aluminum or iron, offering durability and resistance to corrosion.

- Pulley: The pulley is connected to the engine’s drive belt system, which powers the water pump. When the engine runs, the pulley spins, driving the impeller.

- Bearing Assembly: The bearing assembly supports the impeller shaft, ensuring smooth rotation. Bearings are typically sealed to prevent coolant leakage and contamination.

- Seals and Gaskets: These components prevent coolant from leaking out of the water pump. Seals are placed around the impeller shaft, while gaskets are used between the pump housing and engine block.

How a Water Pump Works in a Car

The water pump operates through a simple yet effective mechanical process. When the engine starts, the drive belt-often called the serpentine belt-engages the water pump pulley. As the pulley turns, it spins the impeller, creating centrifugal force. This force pushes the coolant from the center of the impeller outward through the pump housing and into the engine’s cooling passages.

Detailed Operation Steps:

- Engagement: As the engine runs, the drive belt turns the water pump pulley, initiating the pumping action.

- Coolant Intake: Coolant is drawn into the pump from the radiator via a central inlet in the housing. This is usually done at the front of the engine block.

- Centrifugal Force Generation: The spinning impeller generates centrifugal force, pushing the coolant outward into the engine’s cooling passages.

- Coolant Distribution: The coolant flows through the engine block and cylinder head, absorbing heat as it moves. The heated coolant is then directed back to the radiator to be cooled before returning to the water pump.

- Continuous Cycle: This process continues as long as the engine runs, maintaining a consistent coolant flow and temperature regulation.

Types of Water Pumps

While the basic operation of water pumps is similar, there are different types used in vehicles, depending on the engine design and cooling requirements.

- Mechanical Water Pumps: These are the most common type, driven by the engine’s serpentine or timing belt. They provide a constant flow of coolant proportional to the engine speed.

- Electric Water Pumps: Found in some modern vehicles, these pumps are powered by an electric motor rather than the engine. They offer variable speed control, improving fuel efficiency and reducing emissions by providing cooling only when needed.

- Auxiliary Water Pumps: Some vehicles use an auxiliary pump to circulate coolant in specific conditions, such as cooling the turbocharger or ensuring cabin heat when the engine is off.

Common Water Pump Issues

Over time, water pumps can develop issues due to wear and tear. Identifying these problems early can prevent engine damage and costly repairs.

- Coolant Leaks: One of the most common signs of water pump failure is coolant leakage. This can occur due to worn seals or gaskets, leading to coolant pooling under the vehicle or around the pump housing.

- Noisy Operation: A failing water pump may produce a grinding or whining noise, often caused by worn bearings or a loose impeller.

- Overheating: If the water pump fails to circulate coolant properly, the engine may overheat, indicated by a rising temperature gauge or warning light on the dashboard.

- Steam or Smoke: In severe cases, steam or smoke may emanate from under the hood, signaling a serious cooling system problem.

- Corrosion and Erosion: Over time, the impeller and housing can suffer from corrosion or erosion, particularly if the coolant is not replaced regularly or if incorrect coolant is used.

How to Replace a Water Pump

If you suspect a water pump issue, it’s crucial to diagnose the problem accurately. Here’s a basic guide:

- Visual Inspection: Check for any visible leaks, corrosion, or damage around the water pump area. Look for coolant residue or pooling under the car.

- Listen for Noises: Start the engine and listen for unusual sounds from the water pump area. A high-pitched whine or grinding noise could indicate bearing failure.

- Check Coolant Levels: Low coolant levels can also hint at a leak, either from the water pump or another part of the cooling system.

- Test Coolant Pressure: Use a coolant pressure tester to check for leaks in the system, including the water pump.

If the water pump needs to be replaced, it’s a job that requires some mechanical expertise. The process generally involves:

- Draining the coolant system

- Removing the drive belt

- Detaching any components blocking access to the water pump

- Unbolting the water pump and cleaning the mounting surface

- Installing a new pump with fresh gaskets and seals

- Reassembling the components and refilling the coolant

After replacement, it’s important to bleed the cooling system to remove any air pockets, ensuring efficient coolant circulation.

Maintenance Tips to Extend Water Pump Life

Regular maintenance can significantly extend the lifespan of your car’s water pump. Here are some tips:

- Regular Coolant Changes: Follow the manufacturer’s recommendations for coolant replacement. Fresh coolant contains additives that prevent corrosion and lubricate the water pump.

- Check Belt Tension: Ensure that the drive belt is properly tensioned. A loose belt can slip and cause the water pump to operate inefficiently, while an overly tight belt can put undue stress on the pump bearings.

- Inspect the Cooling System: Regularly inspect the cooling system for leaks, cracks, or other signs of wear. Early detection of issues can prevent major problems.

- Use the Right Coolant: Always use the coolant type recommended by the vehicle manufacturer. Using the wrong type can cause chemical reactions that damage the water pump and other cooling system components.

- Monitor Engine Temperature: Keep an eye on the temperature gauge and address any signs of overheating immediately to avoid water pump and engine damage.

Conclusion

The water pump plays a vital role in maintaining your car’s engine temperature, ensuring that it operates efficiently and safely. By understanding how the water pump works and following regular maintenance practices, you can prevent common issues and extend the life of this essential component.