Valve cover torque specs refer to the specific amount of force needed to properly secure the valve cover bolts. Applying the correct torque is crucial to prevent oil leaks, avoid damage to the gasket, and ensure a proper seal. Over-tightening can warp or crack the cover, while under-tightening can lead to leaks.

The valve cover is an essential part of an engine that protects the top portion of the cylinder head and prevents oil leaks by sealing the valve train area. When installing or re-installing a valve cover, proper torque specifications are crucial to avoid damaging the gasket or cover and to ensure a leak-free seal. Over-tightening or under-tightening the valve cover bolts can result in oil leaks, warped covers, or even damage to the cylinder head.

Contents

What is a Valve Cover Torque Spec?

The valve cover torque spec refers to the specific amount of force (measured in foot-pounds or inch-pounds) that should be applied to the bolts when securing the valve cover to the engine. Proper torque ensures that the gasket forms a tight seal between the valve cover and the engine without crushing or distorting it. Using the right torque prevents oil leaks and damage to the valve cover or cylinder head.

Each vehicle has its own specific torque specification, which is typically listed in the service manual or by the vehicle manufacturer. It is essential to follow these specifications to avoid costly repairs and maintain optimal engine performance.

Why is the Valve Cover Torque Spec Important?

The torque spec for the valve cover bolts is critical for several reasons:

1. Prevents Oil Leaks: Applying the correct torque ensures that the gasket is compressed evenly, which creates a proper seal. Over-tightening can crush the gasket, leading to premature failure, while under-tightening may result in oil leaks due to inadequate sealing.

2. Prevents Damage to the Valve Cover: Valve covers are often made of aluminum or plastic, which can be easily damaged by over-tightening. If the bolts are torqued too tightly, the cover can warp, crack, or deform, causing improper sealing and leaks.

3. Protects the Cylinder Head: The cylinder head is typically made of aluminum and is softer than the steel bolts used to secure the valve cover. Over-torquing the bolts can strip the threads in the cylinder head, leading to expensive repairs.

4. Ensures Proper Engine Performance: A loose or improperly installed valve cover can allow oil to leak onto the engine, which can cause performance issues such as oil burning, misfires, or even engine damage. Proper torque ensures the cover stays in place, protecting the engine.

How to Find the Correct Torque Spec for Your Vehicle

Finding the correct torque spec for your vehicle’s valve cover is essential before performing any maintenance. Here’s how to locate the information:

1. Consult the Vehicle’s Service Manual: The most reliable source of information is the vehicle’s service or repair manual. These manuals provide specific torque specs for each component, including the valve cover. They also include instructions for the correct tightening sequence.

2. Manufacturer’s Online Resources: Many vehicle manufacturers provide repair and maintenance information online. Websites and technical service bulletins (TSBs) from the manufacturer may list the correct torque specs.

3. Aftermarket Repair Manuals: Aftermarket repair manuals, such as those from Chilton or Haynes, often contain the torque specifications for common repairs, including valve cover torque specs.

4. Online Automotive Forums: Automotive forums and enthusiast groups for specific makes and models can be helpful resources for torque specs. However, always cross-check this information with official sources to ensure accuracy.

How to Properly Torque a Valve Cover

Now that you understand the importance of valve cover torque specs, here’s how to properly torque the bolts during installation.

Step 1: Prepare the Surface

- Clean both the valve cover and the cylinder head surface thoroughly. Remove any old gasket material or debris to ensure a smooth surface for the new gasket.

- If you’re replacing the valve cover gasket, ensure you use the correct type of gasket for your engine, whether rubber, cork, or a liquid gasket.

Step 2: Install the New Gasket

- Place the new gasket onto the valve cover or cylinder head. If your gasket requires adhesive or sealant, apply it as directed by the manufacturer.

- Ensure the gasket is properly aligned and seated in the gasket groove, if applicable.

Step 3: Place the Valve Cover

- Carefully position the valve cover over the cylinder head, ensuring it sits evenly and that the gasket remains in place.

Step 4: Hand-Tighten the Bolts

- Begin by hand-tightening all of the valve cover bolts to ensure the cover is evenly secured. Do not apply any significant force at this stage-just enough to hold the cover in place.

Step 5: Use a Torque Wrench

- Set your torque wrench to the specified torque (consult your vehicle’s manual for the exact torque specification). The torque wrench ensures you apply the precise amount of force required.

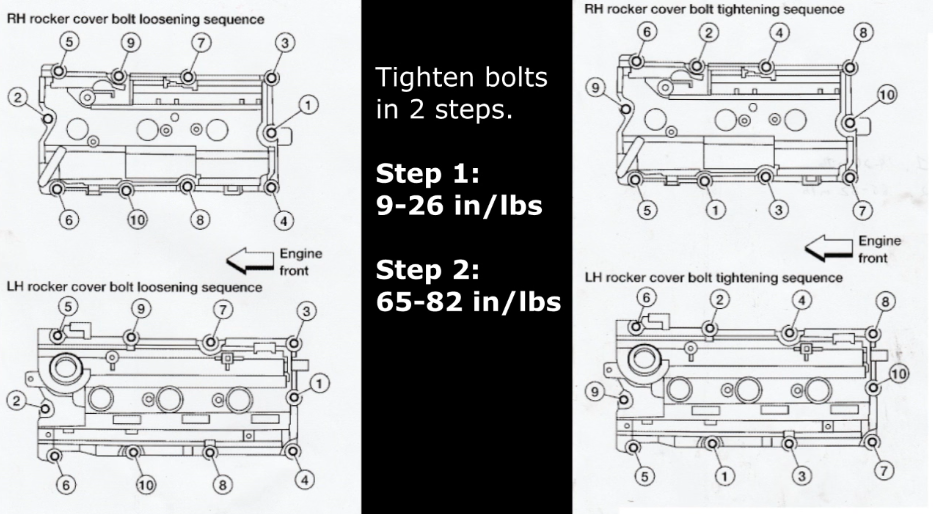

- Start tightening the bolts in a cross or star pattern to distribute the force evenly across the valve cover. This pattern prevents warping or uneven compression of the gasket.

Step 6: Tighten in Increments

- Gradually tighten the bolts in increments until you reach the final torque value. For example, if the torque spec is 8 ft-lbs, tighten all the bolts to 4 ft-lbs first, then go back and tighten to the final 8 ft-lbs. This ensures an even seal.

Step 7: Recheck After a Few Miles

- After driving the vehicle for a few miles or after the engine has been heated and cooled, recheck the torque to ensure the bolts remain properly tightened. This step is particularly important for gaskets that compress over time.

Common Valve Cover Torque Specifications

Torque specifications for valve covers vary by vehicle make and model, but here are some general guidelines for reference:

- 4-cylinder engines: Typically require 3 to 7 ft-lbs of torque.

- V6 and V8 engines: Typically require 5 to 10 ft-lbs of torque.

- High-performance engines: These may have specific requirements, so it’s critical to consult the manufacturer’s guidelines.

Always refer to your vehicle’s service manual for the exact specifications.

Common Mistakes to Avoid

Here are a few common mistakes people make when torquing valve covers and how to avoid them:

1. Over-tightening the Bolts: Over-tightening is a common mistake and can cause damage to the valve cover, gasket, or cylinder head. Always use a torque wrench and follow the recommended specifications.

2. Skipping the Cross-Pattern Tightening: Failing to tighten the bolts in a cross-pattern can result in uneven pressure on the gasket, leading to leaks. Make sure to follow the correct tightening sequence for your engine.

3. Not Rechecking the Torque: Gaskets can compress over time, which may cause bolts to loosen. Always recheck the torque after driving a few miles or after the first heat cycle of the engine.

Frequently Asked Questions

Here are some FAQs about the valve cover torque spec –

1. What happens if I over-tighten the valve cover bolts?

Over-tightening the valve cover bolts can crush the gasket, causing it to leak prematurely. It can also warp or crack the valve cover and strip the threads in the cylinder head, leading to costly repairs.

2. Can I hand-tighten the valve cover bolts without a torque wrench?

While it’s possible to hand-tighten the bolts, it’s not recommended. A torque wrench ensures you apply the precise amount of force needed. Hand-tightening risks under or over-tightening, both of which can cause leaks or damage.

3. Do I need to use sealant on the valve cover gasket?

In most cases, modern valve cover gaskets are designed to be installed without sealant. However, some vehicles may require a small amount of RTV (Room Temperature Vulcanizing) sealant at specific locations, such as corners. Always follow the gasket manufacturer’s instructions.

4. Can a loose valve cover cause oil leaks?

Yes, a loose valve cover will not provide a proper seal, allowing oil to leak from the engine. If you notice oil leaking around the valve cover, check the torque on the bolts and tighten them to the correct specification.

5. What torque should I use for a valve cover on a plastic valve cover?

Plastic valve covers require much lower torque values compared to metal covers, typically around 4 to 7 ft-lbs. Over-torquing a plastic valve cover can cause it to crack or warp. Always refer to the manufacturer’s specifications for the correct torque.

Conclusion

Properly torquing the valve cover bolts is essential for maintaining a leak-free engine and ensuring the longevity of your engine components. Always follow the specific torque specs provided by your vehicle’s manufacturer, and use a torque wrench to avoid over-tightening or under-tightening. By doing so, you’ll prevent oil leaks, damage to the valve cover and cylinder head, and ensure that your engine operates smoothly.